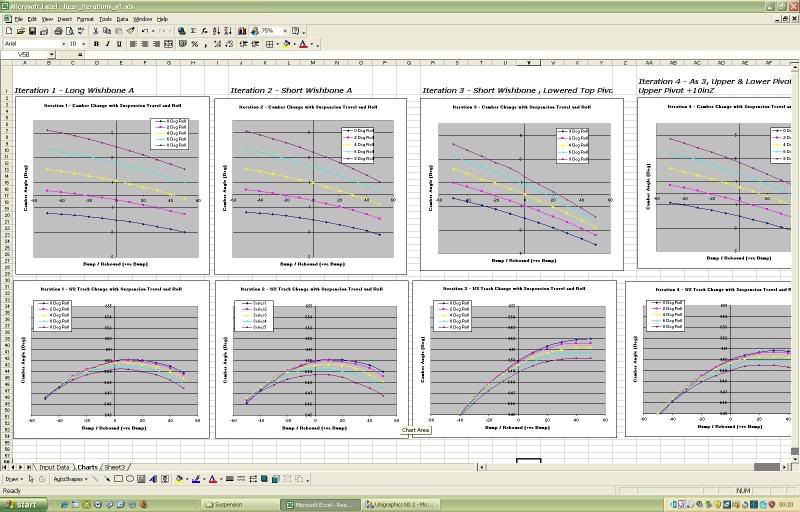

Well, not much to show for the progress this week other than a few more graphs and lots more thought.

Its been kind of mentioned in another thread that its best to "get out in the garge and do it! instead of doing loads of bla bla!", and I don't know if that was actually directed at me or not, but either way man didn't walk on the moon without some prior preperation, engineering thought and planning so I'll carry on as I am and try to make the best design possible before cutting metal. Others can attempt to imitate Z cars or whatever (this forum abounds with people trying to copy them), but to do something original I don't believe the first steps should involve the angle grinder. Also - if you are going to invest several thousand pounds of your own money into producing a vehicle, I'd rather stretch my brain before my biceps. I am a professional automotive engineer too, so its not my culture to not think about things first.

Anyway, there rests the case for the defence!

It was supposed to be a field trip today. I have a friend who gets involved in the garage work (or has on previous projects) and we had planned to go to the Donington Motor Museum yesterday to have a look at suspension construction etc on all of the old F1 cars etc that are there (

Some photos from the web). These days the techniques used to make uprights / wishbones etc are far beyond the capabilities of a home engineer - but back in the 60's and 70's they were mostly fabricated steel so it would be a useful trip I think. Unfortunately, Matt (my assistant) has been taken with some bug that's going round so its been postponed until next week.

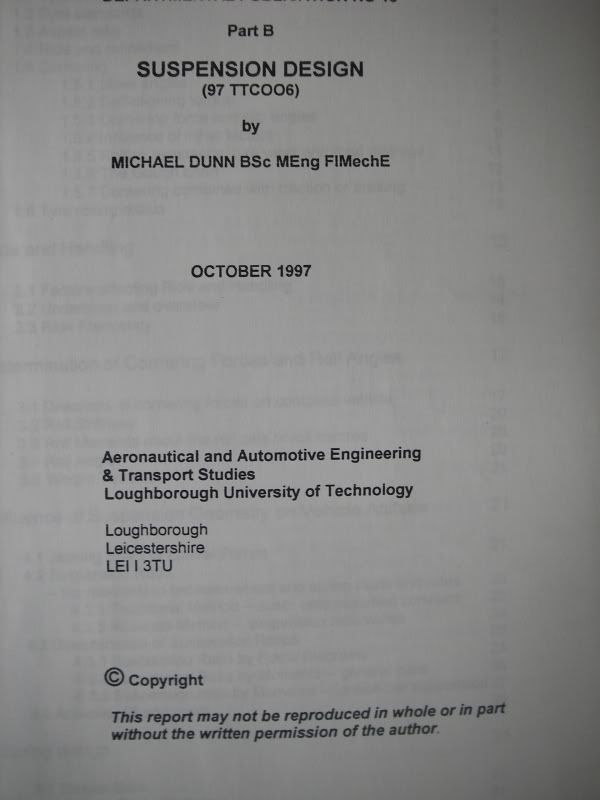

Instead of going to Donington, I decided to clear out my spare room and loft. A long overdue exercise. It proved to be a good thing, because I came across some notes from University I thought were long lost. Amongst them these:

Which should really help, as there are some worked examples with actual numbers for roll etc in them. Mike Dunn (the lecturer) was chief engineer for Ford on the Sierra project, so he should talk some sense.