Hmmm no replies since last time when I had the turbo visible for the first time - thought someone would have noticed!!

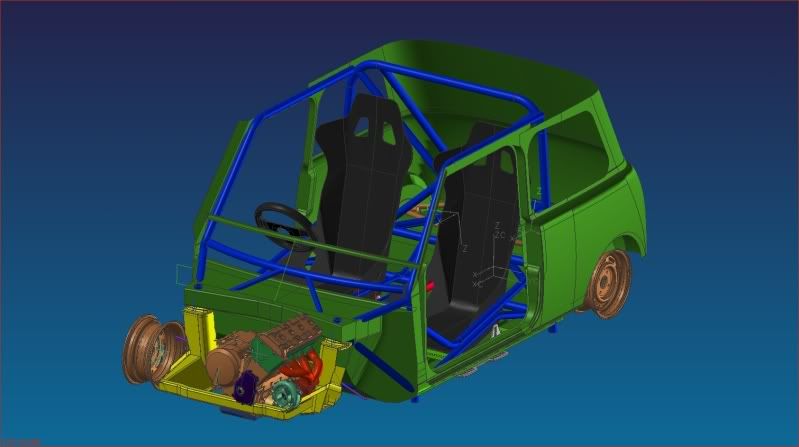

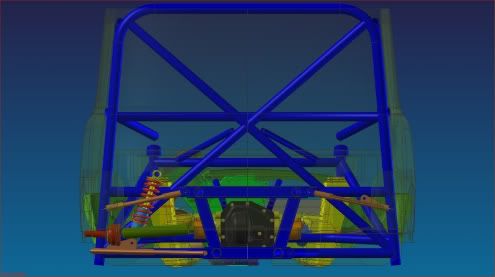

Anyway, I have been busy again this week, and I reckon the thing is starting to look like a car now. I have some concern over the rollcage weight though. According to the computer, at the moment I am just shy of 70Kg for the added structure. Seems a bit heavy to me, but at the same time I have gone a little bananas with it in places (trans tunnel for one) so there is the possibility of removing some weight there perhaps. I am working on a spreadsheet with all the component masses etc and their locations on the car to give me a theoretical final weight, COG height and weight distribution so when thats a bit more advanced it might be time to get the axe out and try to take some weight out of the design. Its not been possible to fully populate this spreadsheet up until now because I didn't really know enough information, but thats changing as I design bits and decide whats what.

One good thing - I finally found out an all up steel body weight - with boot, bonnet and doors the body weighs 155Kg apparently. I now need to weigh the door and front panel I still have off the red mini and the bonnet / boot to get an idea of the total monocoque weight. I'll guess what the wings weigh... With that done I'll know how close to my target I am (in theory). I guessed about 70Kg a while ago, and I might not have been too far off, perhaps a little under.

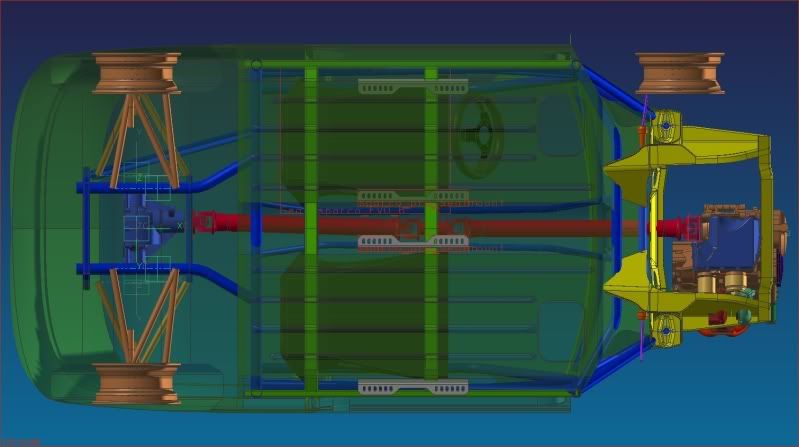

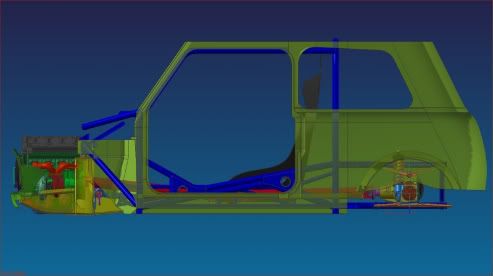

This week started out with the engine installation - trying to tie that down properly, and I then moved onto the rear suspension design and the structure required for the pick up points. Exhaust fits front to back, and the exhaust manifold clears the suspension tower of the standard subframe (JUST!). I know where the intercooler is going, and how I'm going to plumb to it from the turbo. Airbox is gonna be a bit of a pain mind - probably draw air from the LH wheelarch (should be nice and cool there). Got as far as I want go with that right now, so I moved on and I'm now working on the rear suspension etc.

Going on the current accepted best practice of using the longest wishbones possible, and using some first guesses of KPI and camber etc for the rear end, I ended up with a first scheme as shown. Before its possible to tie this down properly I need to model in the front suspesion so I can determine roll moment distribution etc... Can't do one end inpendently of the other as thats not how they work! Its now also time to get some brake calipers into the machine and think about rear wheel bearing setup to allow an upright to be designed. This is going to be what determines my outer wishbone pivot positions, and therefore in turn my inner ones - so its important to move the rear of the car along.

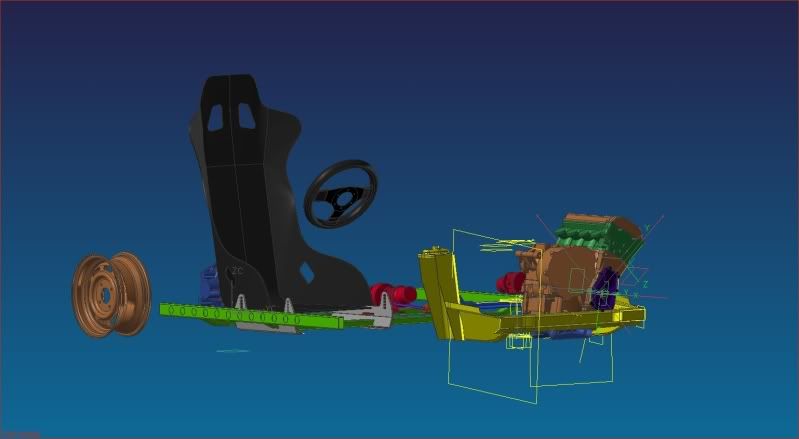

Anyways - enough waffle - here's a couple more images:

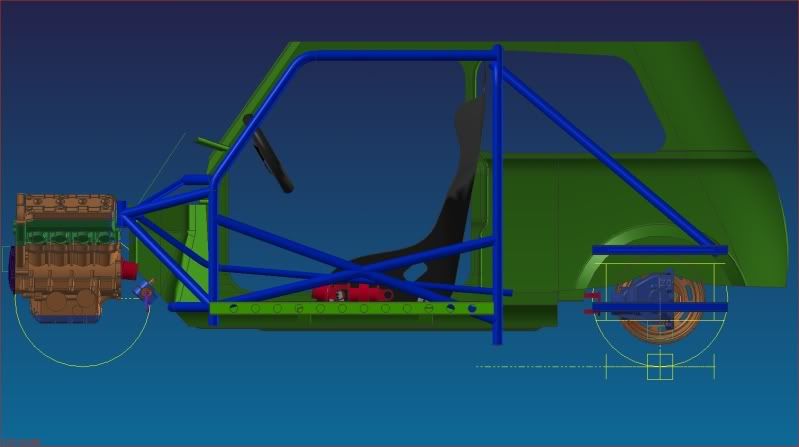

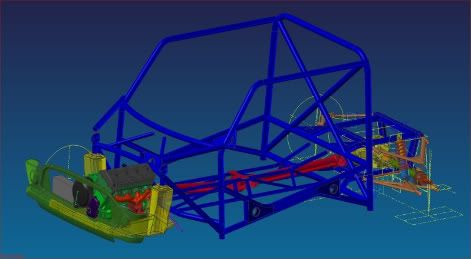

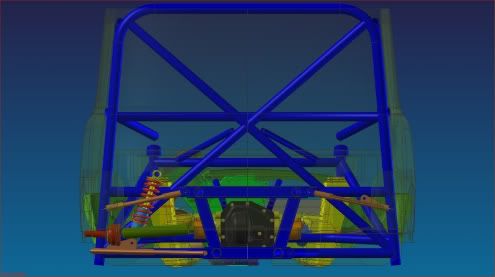

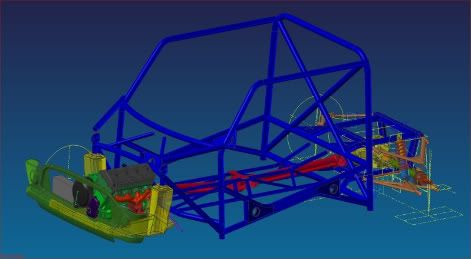

Nakid

There are members missing from the back of the rollcage that run up to the main hoop - before anyone mentions it. I've been moving the pick ups about so much at the back I just deleted them for now.

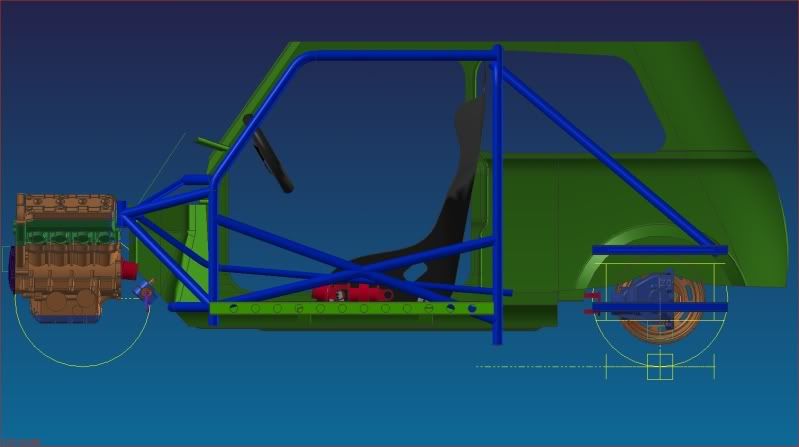

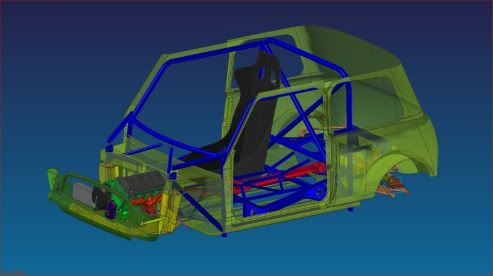

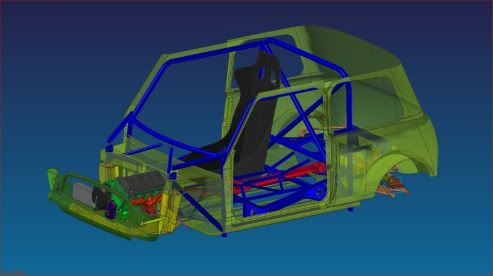

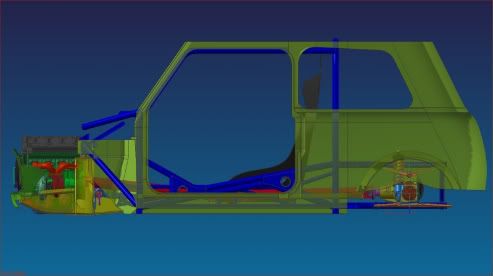

Clothed

As part of the work on the front end I've started to detail the front of the rollcage more. You can see this in the fact that there are a couple of members floating in space! As a concession to manufacturing ease I have changed the way the front subframe pick ups are triangulated a little, but not got round to moving those errant tubes just yet.....!

Rear End layout...

Edited by SukiDawg, 20 June 2009 - 05:06 PM.