#991

Posted 02 September 2010 - 10:31 PM

My advice though, either cover them in oil/wd40 now or degrease them and get them etched and primed. The raw metal took like 24 hours to show surface rust where my finger prints were.

#992

Posted 03 September 2010 - 08:10 PM

Closing bracket was showing signs of rust so I thought I'd replace it while I was down here, I'd done the other side so I figured I might as well.

Found the outer lip was full of holes too so I chopped it out.

Cut out a repair.

Welded, dressed and red oxide applied.

Began making the card template for the floor/sill patch. I had marked it out on to steel as well but I don't have a picture of that.

Tomorrow, get that floor section welded in, repair the flange on the back of the companion bin and then the heelboard repair section will be going on. I'm hoping I can get that done and have time to start cutting out the other side ready to start repairing next week. If I really go for it now, I can have her ready for paint in a fortnight.

#993

Posted 03 September 2010 - 08:14 PM

#994

Posted 04 September 2010 - 07:18 PM

More work done today:

Repaired the spot weld flange on the bottom of the companion bin.

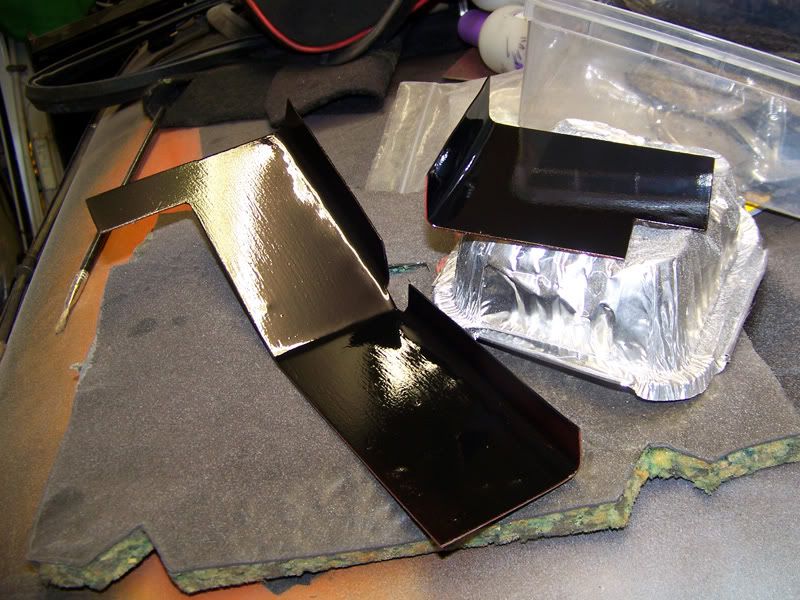

Made up the floor/inner sill patch, the magnets aren't holding it in place very well, it fits quite nicely.

Rubbed down and primed.

Made a patch for the remaining part of the inner sill. Is there supposed to be a spot weld flange on the back of this like this? How does the original inner sill attach to the heelboard, other than with the heelboard reinforcing bracket?

Rubbed down and primed.

Quick splsh of paint to protect them once welded in.

I'm going to go down tomorrow and see about getting those repairs welded in place ready for the heelboard panel to go on.

Thanks for looking

#995

Posted 04 September 2010 - 10:18 PM

EDIT: i cant spell!

Edited by tedmcedd, 04 September 2010 - 10:20 PM.

#996

Posted 04 September 2010 - 11:53 PM

I maintain that I think the end of my inner sill is wrong though, I don't think it should have a flange for spot welding. I think the end of the sill is supposed to be seam welded to the heelboard from inside the companion bin, alot of fun that will be to do!

#997

Posted 05 September 2010 - 10:42 AM

#998

Posted 05 September 2010 - 11:40 AM

#999

Posted 05 September 2010 - 12:09 PM

#1000

Posted 05 September 2010 - 05:21 PM

Repair sections tacked in place. I offered the heelboard repair up to check they were in the right place.

Seam welded up.

Welds dressed.

All welded in.

Subframe used to offer up heelboard repair. Needs to be shortened a little bit to fit in the right place.

I'll whip the heelboard section back out tomorrow, shorten it and drill the holes needed for plug welding.

Thanks for looking

1000th reply!

#1001

Posted 05 September 2010 - 05:41 PM

Do you think I'll have problems with strength as I don't have the rear bins anymore?

And are you plug welding the whole way around?

#1002

Posted 05 September 2010 - 05:54 PM

I'll be plug wedling all round except on the left where the patch meets the heelboard, that'll be seam welded. Basically I'll be welding it back in as original.

#1003

Posted 05 September 2010 - 07:05 PM

#1004

Posted 05 September 2010 - 11:31 PM

JR

#1005

Posted 06 September 2010 - 12:21 AM

Cheers JR, I'll have to spot weld it as I just can't get access to the back of it to seam it to the heelboard.Looking good! On my Estate there was no flange on the back edge of the floor extension which fits up to the heelboard - just seam welded, but it may be slightly different on the saloon. In any case the repair you have made is at least as strong as the original,

JR

I imagine the majority of the stress at that point will be transferred from the heelboard to the inner sill via the strengthening brackets joining them.

More tomorrow...well today, if I go to bed!

Also tagged with one or more of these keywords: roundnose

Projects →

Mini Saloons →

Mini Cooper Project - Finally StartsStarted by piphatch , 08 Jan 2025 |

|

|

||

Projects →

Mini Saloons →

1965 Austin Mini Restoration - Canadian Mk1Started by DoubleEh , 14 Nov 2022 |

|

|

||

Projects →

Mini Saloons →

Project Joe - 1991 Mini Mayfair 998Started by Eggers , 02 Jun 2022 |

|

|

||

Projects →

Mini Saloons →

Mpi Dashboad ProblemStarted by mikeprez , 22 Dec 2021 |

|

|

||

Projects →

Mini Saloons →

1978 Oew - Willy The MiniStarted by smalltreegrower , 11 Nov 2021 |

|

|

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users