#706

Posted 30 December 2009 - 11:51 PM

i need to stop being lazy and get working on the mk2... lol!

leave the drums as they are i say!

#707

Posted 31 December 2009 - 12:54 AM

Cheers

Andy

#708

Posted 31 December 2009 - 02:08 PM

#709

Posted 28 January 2010 - 09:30 PM

Rusty closing panel.

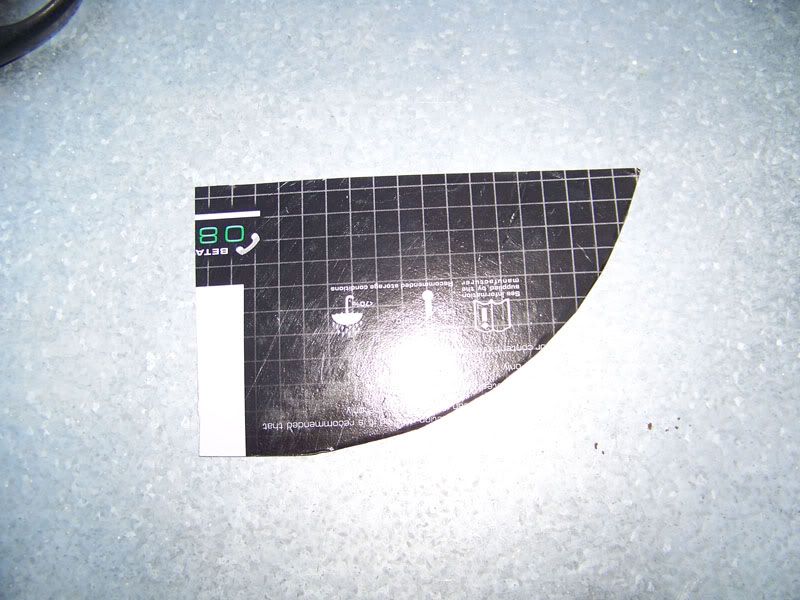

Cardboard template made to record the shape.

Choppy choppy.

From the inside.

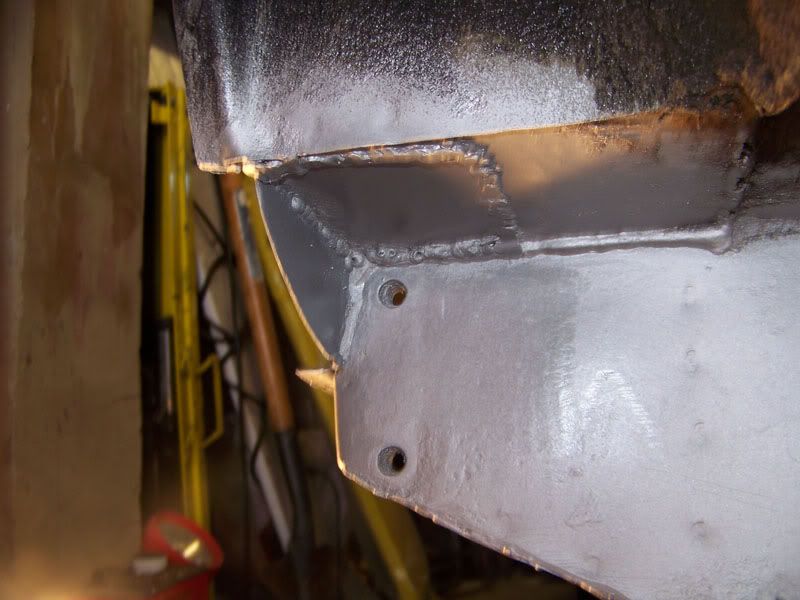

Started the repair.

Quater that needs work.

That was it for that day, this was done before I had to go to Uni for a lecture so not bad!

Now here is the todays update.

What I had to work with.

Another piece let in and both seam welded.

Beneath.

Welds ground back roughly.

Beneath.

Bit of filler work.

Zinc primer.

Beneath, again.

Bit of high build.

Looks ok, still needs a bit more work to get it smooth enough for paint but there is plenty of time for that while I work on the welding.

Thanks for looking guys and girls, sorry for the really scattered updates!

#710

Posted 29 January 2010 - 03:04 PM

#711

Posted 29 January 2010 - 03:48 PM

Thankyou sirLooking good mate

If the weather stays good I'm going to head round and do some more work on her tomorrow.

#712

Posted 03 February 2010 - 04:54 PM

Anyone who's read the Bingley thread in the Events section will know on my way back from Bingley, the front driver side wheel bearing on my daily drive seized (while doing 70MPH on the M6), which made for a bit of a concerning experience which basically has left me a bit apprehensive about driving Minis. Especially as the wheel bearing was looked at by a garage in December and they deemed it to be fine.

Anyway, as a result of this I've decided that despite the cost, I'm going to do the following on Elliot's mechanical bits:

- Get radius arms professionally reconditioned

- New rear wheel bearings, both sides

- New front wheel bearings, both sides

- New ball joints, both sides

- New callipers

- New brake shoes

- New brake pads

- New copper brake lines

- New braided brake hoses

- New rear brake cylinders

- New brake shoes (and springs)

- New knuckles (front and back)

- New bushes all round

I was contemplating replacing the rear subframe as well, but there is a good few years of life left in this one yet, and at £300 a pop, it's best to get the most out of it. I'll be giving the car a thorough once over every few months when it's on the road anyway. I love Minis and I intend to keep driving them

Edited by Deathrow, 03 February 2010 - 04:59 PM.

#713

Posted 03 February 2010 - 10:51 PM

Anyone who's read the Bingley thread in the Events section will know on my way back from Bingley, the front driver side wheel bearing on my daily drive seized (while doing 70MPH on the M6), which made for a bit of a concerning experience which basically has left me a bit apprehensive about driving Minis. Especially as the wheel bearing was looked at by a garage in December and they deemed it to be fine.

I wouldn’t be surprised if the garage just torqued up the wheel bearing a bit more with the old windy gun to remove any pay. The only problem is that then over loads the bearings, heats them up and you know the rest...

#714

Posted 03 February 2010 - 11:00 PM

Well he told me that the squeaking from the wheel (that's what I took it in for) was because some crud had got behind some seal or something so he said he'd had it apart, cleaned it and re-greased it. This did solve the squeaking, which then returned shortly before the bearing failed!Anyone who's read the Bingley thread in the Events section will know on my way back from Bingley, the front driver side wheel bearing on my daily drive seized (while doing 70MPH on the M6), which made for a bit of a concerning experience which basically has left me a bit apprehensive about driving Minis. Especially as the wheel bearing was looked at by a garage in December and they deemed it to be fine.

I wouldn’t be surprised if the garage just torqued up the wheel bearing a bit more with the old windy gun to remove any pay. The only problem is that then over loads the bearings, heats them up and you know the rest...

Sigh!

Anyway, having none of that again so I'm replacing all Elliots consumables like that, wheel bearings, ball joints, suspension knuckles. Just to be safe and secure.

#715

Posted 04 February 2010 - 03:56 PM

How I left it last week.

Outer lip tacked in place.

Underside, all sprayed with weld through primer.

Thought I'd make a start cleaning this mess up while I waited for the primer to dry.

I didn't get very far, I did a good job of welding this to everything in the local area haha.

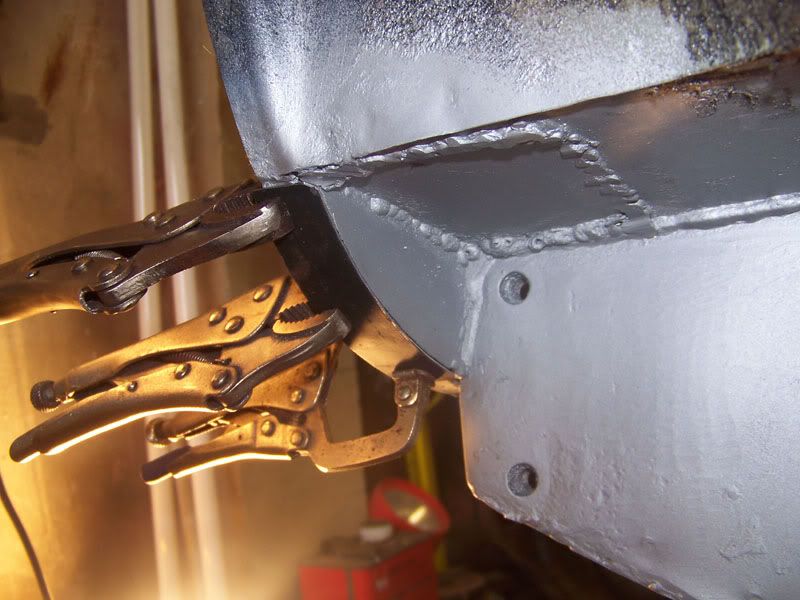

Lipped part of the closing panel repair offered up and clamped in place.

View from the underside.

This is when it started raining unfortunatly. Only one more patch to cut out and tack in place and I can finalise all the welding in that area and start cleaning it all up. I'm working on some mechanical bits and bobs in my Uni room to get that side of the project under way so it'll be completed sooner.

Thanks for looking

#716

Posted 04 February 2010 - 08:21 PM

i miss minis so much....

#717

Posted 04 February 2010 - 08:31 PM

#718

Posted 04 February 2010 - 09:05 PM

Do do do!Top work!

i miss minis so much....may do some work on mine this weekend as im off up home...

I was dissapointed not to see you about at Bingley Ed. I asked Bec if you'd been for your badge and she said you came and got it and legged it! Haha. Next time I'm going to come equipped for Ed hunting.

Cheers sir! It's not very pretty, but it's strong which is what's important. I will be happy when there is no more welding to do though!.your welding is cracking! makes me want to play with my mig in the shed, will keep an eye on this one

#719

Posted 04 February 2010 - 09:06 PM

I'm going to attempt my rear end first, so your photos are brilliant reference

#720

Posted 04 February 2010 - 09:16 PM

Welder: Clarke 130ENWhat settings is your welder on? & what thickness wire are you using?

I'm going to attempt my rear end first, so your photos are brilliant reference

Settings: 1,MIN (Lowest)

Wire: 0.8 gasless.

Wire feed: Can be anywhere between 3 and 6.

My wire speed varies alot depending on what and where I am welding. Like you increase your wire feed if you're welding in to a corner like an L shape. I don't go by setting so much, I try a little bit and if it's not feeling right I'll fiddle until it is feeling right.

Brave man! I hate the rear end, it all seems like such an afterthought, it just doesn't go together as easily or nicely as the front stuff does. Valance closing panels are my worst enemy!

Edited by Deathrow, 05 February 2010 - 01:21 AM.

Also tagged with one or more of these keywords: roundnose

Projects →

Mini Saloons →

Mini Cooper Project - Finally StartsStarted by piphatch , 08 Jan 2025 |

|

|

||

Projects →

Mini Saloons →

1965 Austin Mini Restoration - Canadian Mk1Started by DoubleEh , 14 Nov 2022 |

|

|

||

Projects →

Mini Saloons →

Project Joe - 1991 Mini Mayfair 998Started by Eggers , 02 Jun 2022 |

|

|

||

Projects →

Mini Saloons →

Mpi Dashboad ProblemStarted by mikeprez , 22 Dec 2021 |

|

|

||

Projects →

Mini Saloons →

1978 Oew - Willy The MiniStarted by smalltreegrower , 11 Nov 2021 |

|

|

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users