Please ignore this convoluted story:

Bought a '1380' engine kit second hand, turned out to be an old school effort of a 1380 which basically entailed some pistons from a triumph spitfire requiring a 73.7 bored block. The problem being that I wanted a all singing all dancing 1380, so when i came to upgrade the pistons to omega 7cc offset dish's... they were loose in the bore - New block time.

Intended spec:

73.5mm crosshoned bore A+ block, steel centre main strap, decked 20thou with new core plugs and cam bearings

X-drilled, wedged crank heat treated & balanced

Omega cast 7cc offset dish pistons on S-rods

Kent 286 slot drive scatter cam with high capacity oil pump, kent followers, 1:5:1 rockers - undecided on make

MED 19cc chamber big valve head with 240lb double valve springs

Straight cut box with 4 pin diff, undecided on 4 or 5 speed & make - guessworks on 4 speed thats for sure

Vernia duplex lightened timing gears

Ultralight steel flywheel, racing clutch & orange diaphram

Vandervell bearings all round (AE thrusts)

Praying for 100bhp & 100lbft at the wheels

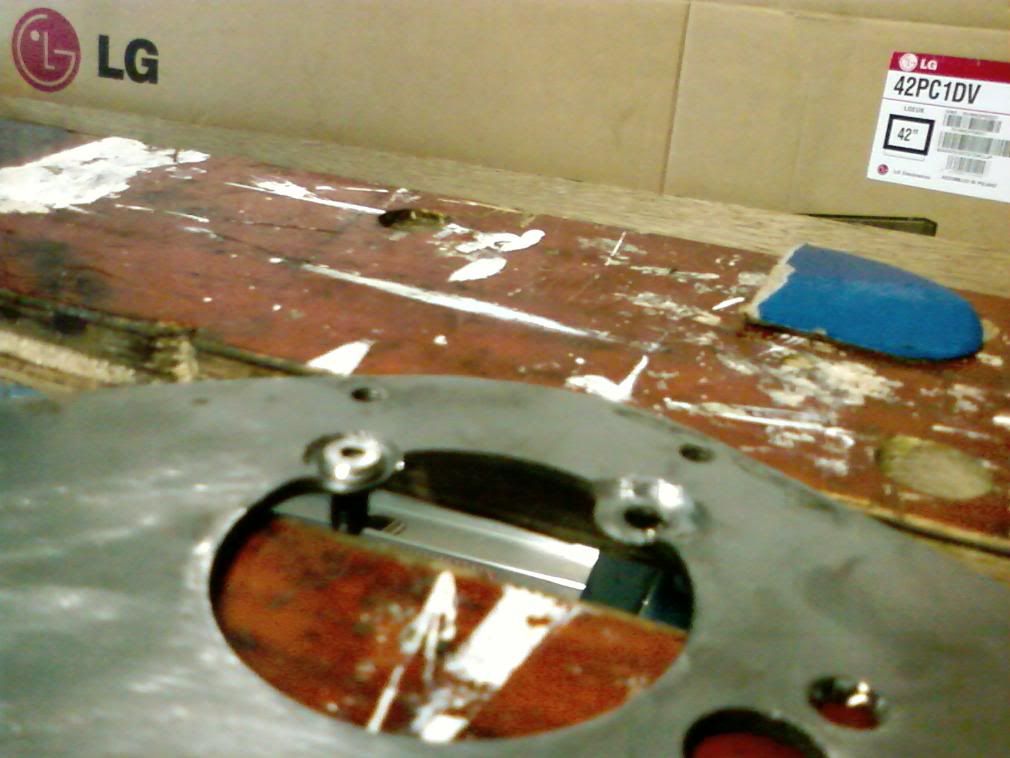

Piccies so far - waiting on AP rod bolts before i go any further... and i know that plastic sheet looks dirty but i assure you its the other side thats bad, its clean as a whistle! engine stand is also on its way.

Kept the res low on the less important piccies

Block

SP_A0108.jpg 25.89K

50 downloads

SP_A0108.jpg 25.89K

50 downloadsCrank

SP_A0109.jpg 21.38K

34 downloads

SP_A0109.jpg 21.38K

34 downloadsOmega on rod

SP_A0110.jpg 24.66K

29 downloads

SP_A0110.jpg 24.66K

29 downloadsTodays work: (picked up decked block & skimmed head - bought a nice new tool box for all my new tools too)

Fitted crank, nice and smooth... nicely oiled up bearings first and offered crank carefully. made sure main caps went back on in same orientation from whence they came

SP_A0113.jpg 101.88K

47 downloads

SP_A0113.jpg 101.88K

47 downloadsThis was a little worry for me, the oil hole doesnt quite line up with the block

Sorry about the quality on this pic, my camera phone isnt the greatest..

SP_A0111.jpg 71.38K

28 downloads

SP_A0111.jpg 71.38K

28 downloadsIll be doing pistons at the weekend hopefully, just waiting on AP rod bolts. Ill get some piccies of the head too whilst im at it.