Morris, The Mini Moke! - 56k Warning

#16

Posted 19 February 2008 - 04:27 PM

#17

Posted 19 February 2008 - 04:40 PM

The removal of the both subframes has happened, and through this job i have never had to break/shear/crack or saw soo many nuts and bolts. The subframe mountings on the body are all rotten and need completely re-making. The moke has been stripped of everything including the Gear Change, The Sub frames, The seats, the windscreen, the guiding poles for the canvas roof and the petrol tank. The petrol tank should have been an easy job of removing some bolts and dropping the cover However the Under seal is actually a tar used on wooden stumps and made all the bolts and nuts seize to one another. Also some of these bolts have been bent out of place, it funny actually, the bent bolts follow a line of destruction along the bottom of the car, starting with bent body work, dented Extension box and scratched underseal. Now everything is off, its a case of getting it up to the Coachworks for the welding to commence. I rang them Monday of Last week, and they were meant to have the builders in that week, and to ring back next week (Today). I rang today and have been told the builders are in this week, and to ring on Friday to see were we stand. This is a huge Knock for the deadline of May 18th.

That not me!

Edited by liirge, 19 February 2008 - 04:42 PM.

#18

Posted 19 February 2008 - 04:40 PM

So glad to get rid of that ugly strip of metal to protect the electrics, SOO ugly!

#19

Posted 19 February 2008 - 04:45 PM

Just got off the Phone to the Coachworks and there STILL having building work done!! GGGGRRRRRRRR. So another week added to the build time, its gonna be tight getting this done by London 2 Brighton!!

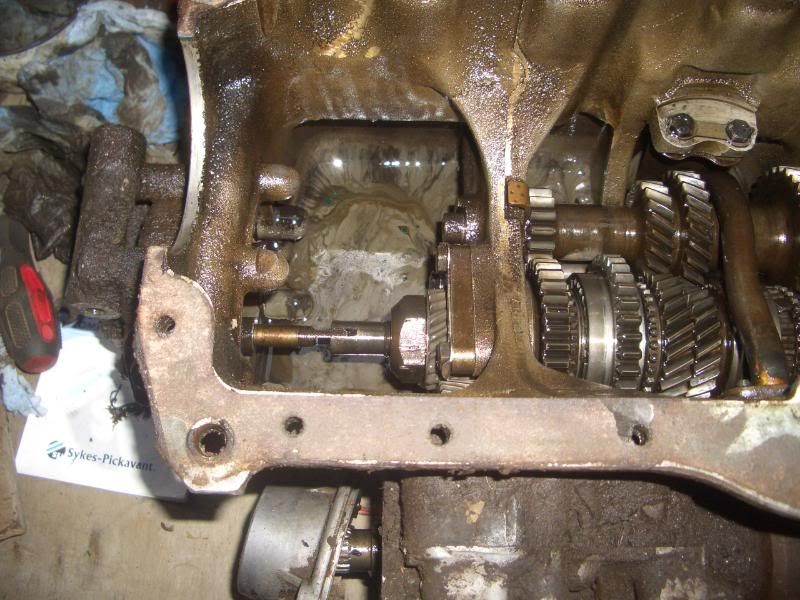

I've actually separated the Transmission and Clutch from the engine, which was a bit of a job.

#20

Posted 19 February 2008 - 04:49 PM

Just had Mr,Seymour, A good friends father who's ex British Leyland, round to have a look at the Moke, specially the engine, he was extremely helpful and am very thankful for his advise and time. It's pretty good news! the engine is fine apart from a couple of tweaks, couple of oil seals, Need to emery paper part of the crank shaft to get rid of some bumps from a moving flywheel. The drain plug needs replacing as the current one is pretty poor!

The arm that comes out of the bell housing, has seized up, and probably due to poor adjustment. An incorrect nut was on the end as well. All in all he seemed very happy with the condition of the car and engine.

He looked at under the pistons and they were fine, and was impressed with how good nick the bores are in. He also checked the oil pressure relief valve, and that was fine. Im very happy with the outcome of the visit!! he also offered to help with the petrol pump and the Dynamo!

#21

Posted 19 February 2008 - 04:50 PM

Rang the coachworks again, and they still have the builders in!!!! Tim told me to ring back in 2 weeks and if im lucky it'll be done. This has really shortened the time available till London to Brighton.

Worked out, that i will need to get the whole car reassembled once back from the coachworks, in 2 weeks.

#22

Posted 19 February 2008 - 04:51 PM

New parts arrive today, including the cylinder head, it looks gorgeous!

#23

Posted 19 February 2008 - 04:53 PM

Taken apart the clutch arm, and the plunger throwout plate still wont budge. The Clevis pin was also stuck solid, so that needed some "Gentle Persuasion" but finally moved!!

The Plunger is now over at Nick Seymours Avon engineering works, were they are going to press it out with Hydraulics!

Did six little jobs yesterday that have been on my mind a little. Manged to get the remains of the knuckle joints out of Upper suspension arms the arms them selves look good, just do with a clean up, file down and a little paint. Removed the Balls from the rear trumpets, they were harder than the front ones.

Decided although only oneof the differential oil seals were leaking i was going to replace both for preventative measures. Lucky i did, as i took the other housing off the oil seal had actually split in half!

Removing the oil seals from the output drives, was just a case of pure brute strength! but finally i managed to pop them out, and with a sigh of relief i can tell you!

#24

Posted 19 February 2008 - 04:54 PM

The Plunger is back they managed to press it out.

I have just spent another 300 odd quid at mini spares on new parts i've worked out there's over 110 new parts going on the moke!! Yikes!

#25

Posted 19 February 2008 - 05:03 PM

all he had was a Nissan micra

#26

Posted 19 February 2008 - 05:04 PM

why didn't my grandfather have something interesting to drive

all he had was a Nissan micra

Yer i have one of those aswell!

#27

Posted 19 February 2008 - 09:32 PM

#28

Posted 19 February 2008 - 10:27 PM

Oh im determined to have her done by london to Brighton, so sure i've bought my ticket!!Great Rebuild! I can't believe how good the body work looks and the lack of severe rust to say it was used on a farm for 25 years!! Be great to see it finished.

It'll be fantastic to get another mini back on the road, every mini counts!

#29

Posted 21 February 2008 - 05:09 PM

Really good news, had absolutely loads of new parts arrive today. important parts for the suspension and all the new seals and gaskets for the engine.

I have also put an order in for several pains and products to bring the Cast iron back to standard!

The coachworks have finally got rid of the builders, and the moke if all goes to plan should have work started on Wednesday morning.

Things are starting to move on.

Feeling a little bit better about the getting her ready for London to Brighton!

#30

Posted 22 February 2008 - 08:01 PM

Im currently doing up my portugues moke, which had some big rust holes in the floor! Fred Flinstone Styleee!

Its just gone off for painting, and I am currently just painting some of the small bits.

Keep going with it! it is definatly worth it, driving it on a warm summers day is sooo much fun!

good luck!

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users