No pics sorry, but it is simple enough,

fuel from pump goes to the large pipe on rail, medium is return and small needs to go to the ITBs after the butterflies, (where it will get vacuum)

For the idle solenoid one air pipe goes before the throttle bodies, but after the filter so its clean air, the other goes after the butterfly on all the ITBs so each gets more idle air.

Can draw pics if you need any more info

Ed,

That sounds fine, I'm not sure yet where to connect the idle, If I put it into the old Yamaha injector positions, I can make a manifold up for it. That leaves the original 4 vacuum connections on the TBs for the Megasquirt connection. I can then cut a thread in the manifold for the Servo connection. I'm a bit concerned that with the brake servo coming off no 1 and the Megasquirt coming off all 4 that the servo vacuum will affect the megasquirt... does it need non-return valves in there somewhere ? Or doesn't

The alternative would be to take the Servo off No 1 and the Megasquirt off No4 only, with non-return valves in the idle connection. Its all a bit of a puzzle

FYI

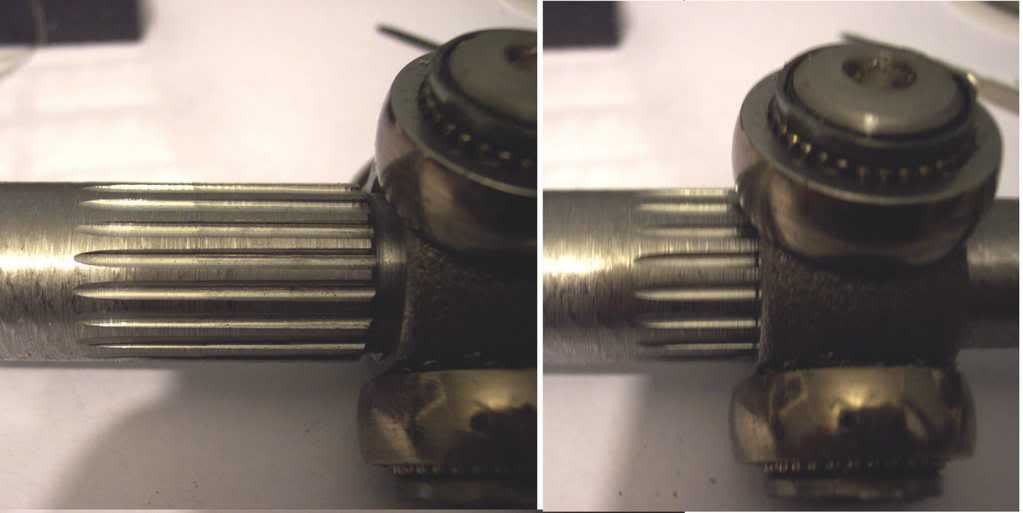

I looked at the setup for the injectors in more detail, the resistance of the standard Suzuki injectors puts them right at the limit of what the megasquirt will run, I think we will put some resistors in series with the injectors, I have some 6.8 Ohm 10 watt, so doubling up that will give 3.2 Ohms 20 Watt or 2.3 Ohms 30 Watt with three for each injector.. If it runs OK with them in, it will help reduce the load on the output of the megasquirt.

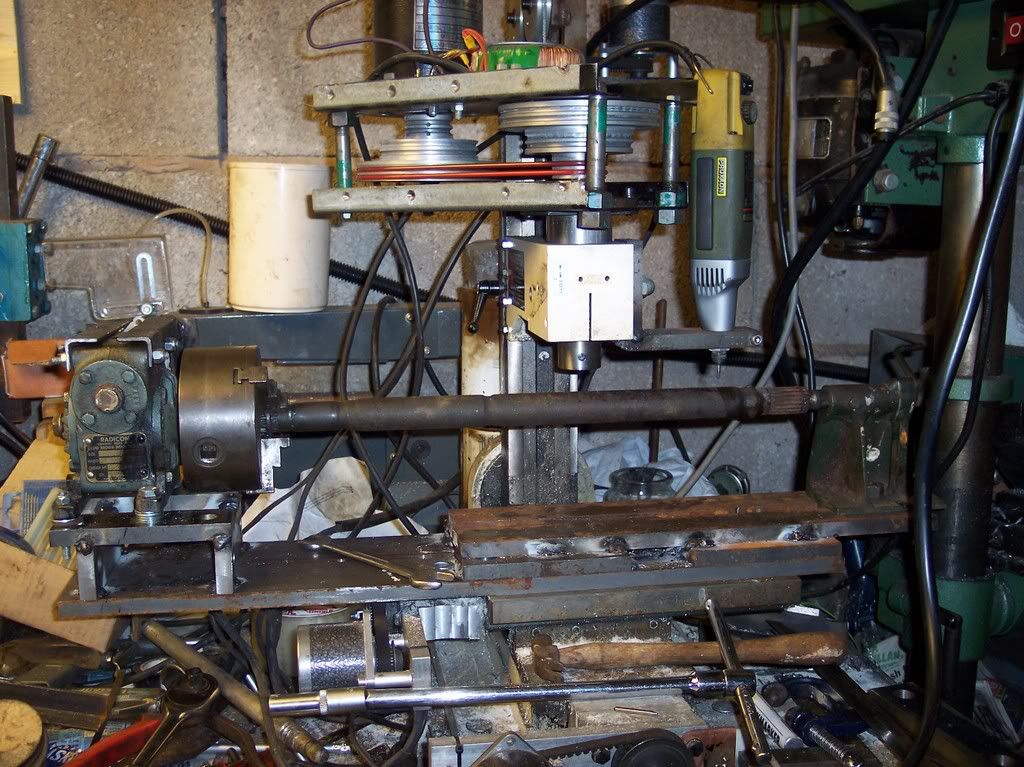

We are leaving the double crankshft pulley on and welding the trigger wheel to the outside of that so that maybe (once the car has been driven for a while and if it's safe) we can use it to drive a supercharger, the ones fitted to the BMW Mini seem to be about the right size, and look as though they will fit above the current inlet manifold. We would have to drop the compression ratio, if we can't find the right pistons, we could CNC a spacer plate with two head gaskets.

Has anyone built a Minuki with a supercharger ?

so much to do and so little time... but making progress... Trigger wheel sensor on tomorrow

)

Chris (iamcabbaged's Dad)

Edited by spiyda, 17 January 2008 - 01:15 PM.