Nissan Micra Engine Transplant

#586

Posted 23 October 2010 - 07:16 AM

Muy bonito:)

[url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02146.jpg"]http://i789.photobucket.com/albums/yy180/h...ed/DSC02146.jpg[/url] [/ img]

[Img] [url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02144-2.jpg"]http://i789.photobucket.com/albums/yy180/h.../DSC02144-2.jpg[/url] [/ img]

[Img] [url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02145.jpg"]http://i789.photobucket.com/albums/yy180/h...ed/DSC02145.jpg[/url] [/ img]

[/ Quote]

It looks very clean and tidy, I have a project micron cbr engine and carbs and I'm interested in knowing how to solve the issue of the distributor, that distributor I can use?, Bigchief, I think using one of micra k10 right?. In your project appears to be mini Lucas65dm4 ok?.

I see you use a piece of aluminum to adapt to micro engine, you can make a sketch, so I do the same.

The distributor uses bigchief not need adaptation

[url="http://img188.imageshack.us/my.php?image=77148725.jpg"][img]http://img188.images...65/77148725.jpg[/url]

#587

Posted 23 October 2010 - 01:38 PM

Hi Miilor.[Nombre citan fecha = 'reglas de plástico' = '22 de octubre 2010, 22:37' post = '1959849 ']

Muy bonito:)

[url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02146.jpg"]http://i789.photobucket.com/albums/yy180/h...ed/DSC02146.jpg[/url] [/ img]

[Img] [url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02144-2.jpg"]http://i789.photobucket.com/albums/yy180/h.../DSC02144-2.jpg[/url] [/ img]

[Img] [url="http://i789.photobucket.com/albums/yy180/harejspeed/DSC02145.jpg"]http://i789.photobucket.com/albums/yy180/h...ed/DSC02145.jpg[/url] [/ img]

[/ Quote]

It looks very clean and tidy, I have a project micron cbr engine and carbs and I'm interested in knowing how to solve the issue of the distributor, that distributor I can use?, Bigchief, I think using one of micra k10 right?. In your project appears to be mini Lucas65dm4 ok?.

I see you use a piece of aluminum to adapt to micro engine, you can make a sketch, so I do the same.

The distributor uses bigchief not need adaptation

[url="http://img188.imageshack.us/my.php?image=77148725.jpg"][img]http://img188.images...65/77148725.jpg[/url]

Yes the distributor is from a late Mini (1995 I think) I have fitted the dizzy with highlowmar (sealant) and dont really want to strip it all down again to measure it.

Basically the bore of the collar is the diameter of the mini dizzy +0.001". The diameter of the bit that fits into the head is the same diameter as the original distributor. The overall diameter is 40mm and the width off the collar on the outside of the engine(so the distributor shaft does not hit the camshaft) is 13mm. Hope that makes sense. The nissan key ( bit that drives off the camshaft) needs to be bored out slightly to fit the mini shaft. The mini key also has to be machined to reduce the thickness so the nissan key can fit onto the shaft far enough. Another point is make sure when you drill through the shaft to fit the pin that secures the key that it is in the right position to the rotor arm( pointing at the correct pole on the cap when number one cylinder on firing stroke) Sounds a bit complicated but when you get started its not too bad. If you are getting someone to do the machining it would be best to show the guy what you are doing rather than just giving him drawings. He might think of an easier way to do it.

Good luck Jim

Edited by harespeed, 23 October 2010 - 01:40 PM.

#588

Posted 24 October 2010 - 07:09 AM

#589

Posted 01 November 2010 - 08:05 PM

Excuse my crappy english. I am from Sweden.

I have a Clubman that I will fit a Micra engine in.

#590

Posted 30 November 2010 - 11:54 PM

#591

Posted 01 December 2010 - 05:55 PM

we have been lookin at this conversion for the past few months and decided last week to make the move. I am making the first subframe for another club member who wont be stressing it as much as i will so we can see areas that we can improve it.

Was delighted to see someone running the engine on the cbr600 carbs as i am also goin to do the same. Hope to post some photos soon, but if i m not bac posting i would like to say to everyone who has contributed to this topic, very well done and congrats on such an informative and conprehensive build tread.

#592

Posted 02 December 2010 - 01:52 PM

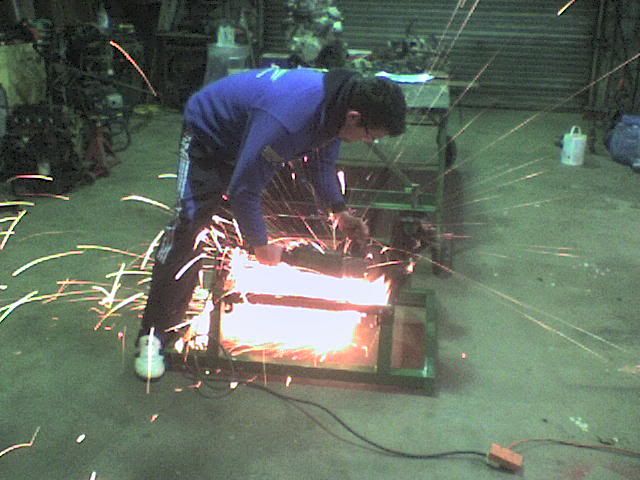

Just a few pics of what we have done so far.

Firstly the boss man built a jig for the subframe, to ensure the whole thing would remain straight throughout the construction.

The sides were removed,

Donkey engine fitted for size, CG10,

Engine removed and then the frame was built up, first tacked in place and then welded.

Cross member added and here is what we had.

Electric hoists are very handy.

Snug fit.

We are waiting on Land Rover engine mounts to arrive so we can make up the mounting brackets, we also need to get a Micra CV joint to see where we are space wise between the CV and the subframe tower.

Also tight on the water pump side too.

Can't do too much now until the post man get's here with the mount.

If anyone has suggestions or comments, please feel free to offer them, all criticism or praise welcomed.

#593

Posted 02 December 2010 - 03:06 PM

Is that you Neil?

#594

Posted 02 December 2010 - 03:37 PM

#595

Posted 02 December 2010 - 06:27 PM

We plan to add strengthening gussets or box to reinforce the sides somewhat. Joe is worried about a potential weakness in case of a frontal collision.

The cone still fits in the turret, it's just that in Drummerian's photo , his engine seems to be much further forward than ours for some reason.

Check out the gap on the left. Ours is almost touching at this point.

#596

Posted 02 December 2010 - 06:36 PM

What do ye think, is this goin to be strong enough to take serious abuse, i m afraid it will fail under the stress

#597

Posted 02 December 2010 - 07:55 PM

I usually build with 10mm of clearance

looking a good start though

#598

Posted 02 December 2010 - 08:36 PM

Very much noted though, is there much give in the Landrover mounts from side to side?

#599

Posted 02 December 2010 - 08:58 PM

I'm hopefully going to be starting mine soon. I picked up a 98 1.3 Micra with 60k on the clock and more rust than most Minis for £150. So far I've made almost half that back selling bits just through word of mouth so I reckon by the time I've pulled the bits I want off I should be easily able to advertise some easily seperatable and saleable items (wing mirrors, bonnet, doors, bootlid etc.) and get the bits I'm using for free.

One question relating to the differences between bigchief's conversions and most of those on here..... Bigchief's fits inside the existing sides of the subframe and ours won't because the gearbox is bigger. But most of those shown are extending both sides of the subframe - does this mean that the engine on these conversions is sitting further to the right? Would there be any mileage in us putting the engine in the same position as Bigchief and having a larger extension just on the one side of the frame? Looking at TMG's pics I'm thinking maybe the pot joints would prevent this.

I've got a slightly different situation to these as it's going in a GTM instead so I don't have a bulkhead behind the engine but I do have one in front of it so I'll need to be a bit careful to keep the exhaust clear of the bulkhead in front of the engine. Also means I don't have to worry so much about interfering with steering.

Iain

#600

Posted 02 December 2010 - 11:31 PM

However, as it s -10 in the shed at the min i m sittin beside the fire for the time being, but i thought of another piece i could make to give even more strenght.

As this subframe is being made for TMG for his estate, i m happy enough it ll be able for his style of driving but i m goin to start mine tomorrow which is the early 4 bolt subfrace for my 76 gt retro rally car. Already i ve seen areas i recon i could double the strenght of the frame.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users