Cheers guys.

Weather finally calmed down abit today. Still really windy but not raining sideways like it has been all week.

I've started grinding out the shock mounts ready for some fresh metal to be welded in by a mobile welder.

Still deciding whether or not to have one thick plate welded in or have 2 thinner ones put in on top of each other like it would be as standard. Also not sure whether or not to keep cutting all the way down the panel, it'd be easier but would mean i'd need to bend a lip into the repair patch.

With the broken studs (on the other side to the pic below) I just used a punch and a mallet to knock them through and snap the threaded block off the inside of the wing. So now i'll just be using 2 nuts and bolts to hold the top of the shock mount on, as you can get to the back of the holes.

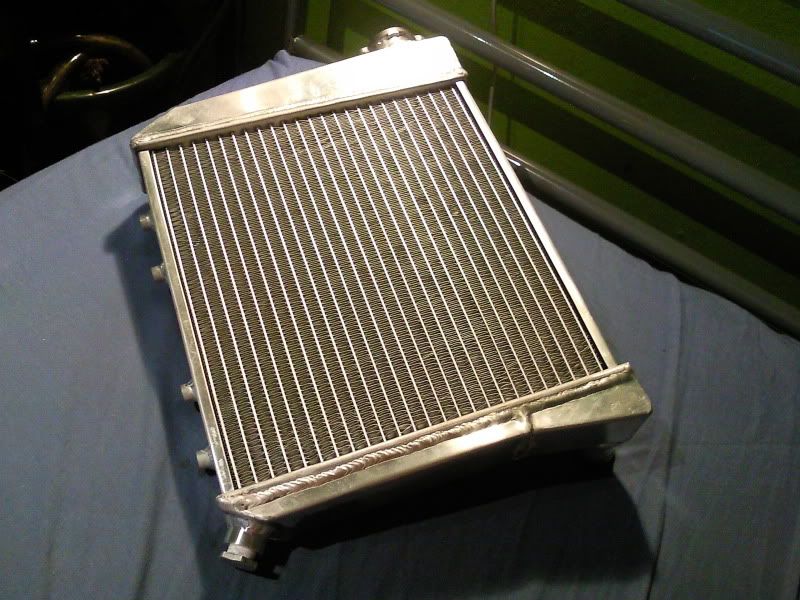

Also fitted the rad today. It fitted pretty easily, just as easy as a standard rad so thats good. I also flushed out the cooling system, just connected one of the heater tubes to the garden hose and left that running for a few mins to blast some of the crud out. I've filled it back up with some clean water and some holts rad flush. So i'm supposed to let the engine fast idle for 10 minutes to let that stuff wash out inside the engine. I had the engine running for a few mins but noticed abit of smoke - Turns out a load of crud that'd flicked off the wire brush from the underside of my car had stuck to the exhaust and was starting to burn. So need to scrape that off before I try again.

Only other thing to say about the rad is that its sitting too close to the fan. The very edge of the fan blades is rubbing on the outer metal of the rad, its no so much of a problem, but obviously needs abit of clearance. So i'll probably just file the holes in the rad housing abit wider to get the rad sit a few mil further out. Also cut about 2cm off the top hose in an attempt to get it to fit better and not kink. Its still got a very slight kink but as good as its going to get.

Couple of pics of rad/engine: