Just looking at that photo makes me worried about the bigger cars all around such a nice mini, you have to drive proper careful now buddy, defensive as hell, esp with big cars like that, one 'i didnt see you, you're too small' and thats your rear end taken out

I'm sure the cars quick enough to evade that though

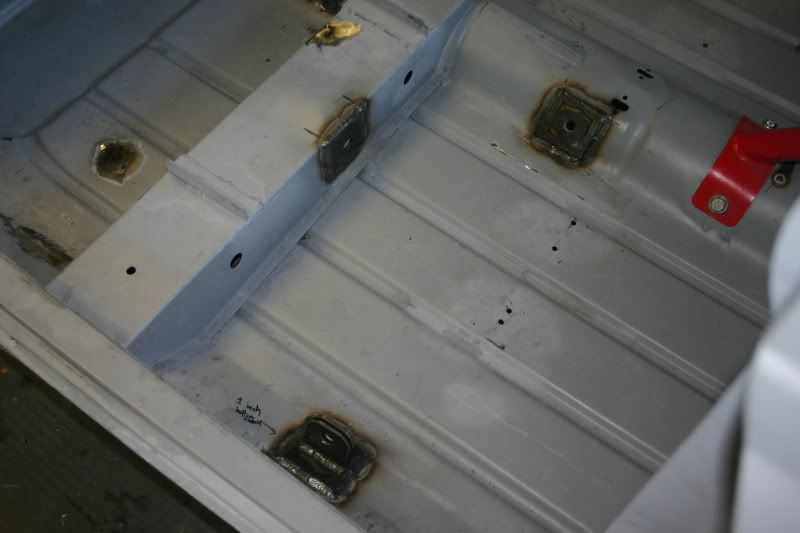

So imagine how his father is going to worry... Vehicles the size of that Toyota truck are the norm around here (sorry to say). That's why the full roll cage, racing seats, 5 point harnesses, relocated fuel tank and dual 118db Hella horns were all agreed to early on in the project.

I'm not at all worried about Chris remembering to drive defensively, not because of any personal sense of the danger (he's 18 after all). I know he will be extremely careful because 1) he's a good driver (OK a little heavy on the gas....) but more importantly by the time this project is done he will have poured so many hours and so much sweat into creating it that he simply will not allow anyone to get close enough to damage his baby!

He's almost done with the flip front and he's done a hell of a good job with it. I'm sure pictures will follow before long.

--------------------------------------------------

Chris: I was just about to post this when you posted your message. Did you make it to Berkely OK or are you wi-fi on the road?