73 fast road mini

#31

Posted 09 November 2007 - 10:15 PM

#32

Posted 09 November 2007 - 11:10 PM

I haven't bolted it in yet as I need to do just a little bit more reconstructive work on the drivers side floor right where the front cage mounts, should get that churned out this weekend so I can get everything all square, the cage bolted in and the door bars cut to fit. Then I just need to pull it back out and paint it

#33

Posted 10 November 2007 - 04:05 AM

If you ever need anything else shipped from abroad, let me know, my brother is a licensed customs broker and has shipped a bunch of stuff for me from the UK, NZ and others for my various Mini projects.

Cheers,

Aric

Thanks, the cage is just a Safety Devices front and rear cage with a harness bar and door bars. got it off minisport in a package deal, then bought the harness bar so the total came out to around 550 pounds, not including the ridiculous shipping ordeal I had with customs, but i guess that comes with living in America.

I haven't bolted it in yet as I need to do just a little bit more reconstructive work on the drivers side floor right where the front cage mounts, should get that churned out this weekend so I can get everything all square, the cage bolted in and the door bars cut to fit. Then I just need to pull it back out and paint it.

Edited by Monte Busa, 26 December 2007 - 05:22 AM.

#34

Posted 10 November 2007 - 06:23 AM

On another note, flipped the car around and pulled of the drivers side sill, which was in decent shape besides the fact that it was an mk1 sill

It's amazing what you can do when you work for 6 hours non-stop...

#35

Posted 10 November 2007 - 06:51 AM

under drivers sill. Pretty good, as far as I am concerned. just a few patches to be done.

hour of work right here. easy.

Where i fixed the floor:

hoping to have it done by this weekend, except for the sill which I just ordered.

#36

Posted 11 November 2007 - 05:30 AM

I am going to need to cut out the section and weld a new flat piece of sheet in its place. Does anyone know how the brackets actually mounted? (Just the two bolts?) I seem to be at a loss here.

#37

Posted 13 December 2007 - 08:27 PM

Maganged to do a bit of work though.

the panels for the rear bumper lip never lined up, and i test fitted it with the bumper and realized that the holes farthest from the body are the ones that fit. so today i begain fixing this little issue. not entirely satisfied, and still needs some filler work but it should look decent when i am done.

also am in the process of mating the innner and outer skins of the bootlid:

in other news, gave up on trying to fit the fiberglass front end. what a waste of money. where it met the scuttle panel the angle was completely different. anybody want it? shipping from califorinia might be a bit... haha

steel 2 piece flipper anyone?

got these guys as well:

and the chassis black paint i got from eastwood is fantastic. the more i use it, the more i like it. here is a saple of it on a radius arm in the sun:

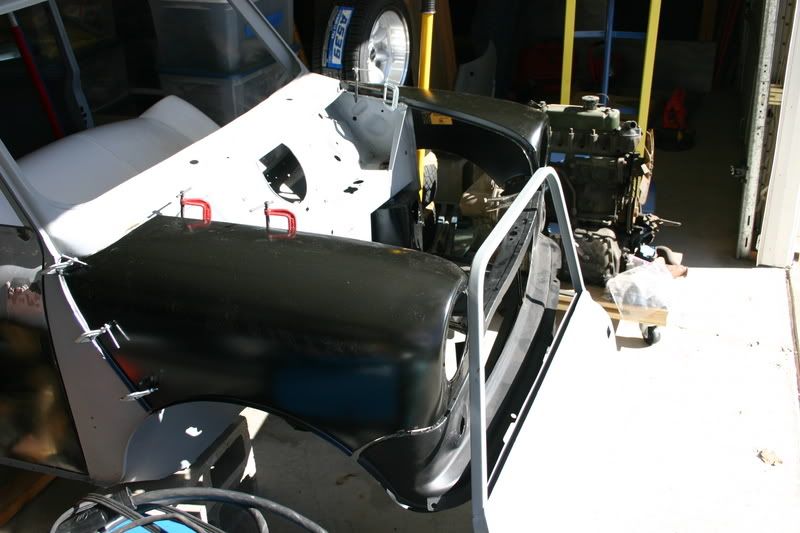

and this picture just for good measure:

#38

Posted 25 December 2007 - 02:17 AM

I figured i wasn't angering the purists enough.

130 horsepower and complete reliability sound good to me...

(P.S. request for this to be moved to non mini engined projects)

#39

Posted 25 December 2007 - 05:08 AM

#40

Posted 25 December 2007 - 05:40 AM

and thank you for moving the thread

#41

Posted 25 December 2007 - 05:50 AM

no probs on moving the thread

#42

Posted 25 December 2007 - 06:50 AM

#43

Posted 25 December 2007 - 07:16 PM

#44

Posted 25 December 2007 - 10:31 PM

Should go like stink!

#45

Posted 26 December 2007 - 04:28 AM

It's a 1500 cc japanese-spec D15B, which makes 130 bhp at 5800 rpm. from what I have heard the 160 bhp B16A2's spin the tires up into forth gear, so i think that i will probably be able to get a little excitement out of it

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users