73 fast road mini

#166

Posted 05 January 2010 - 01:01 AM

#167

Posted 05 January 2010 - 06:12 AM

Finished the bottom of the drivers door, needs a little bit of filler since the non-genuine panel doesn't quite have the same profile as the ridge in the door, but it came out pretty good.

I also lowered the edge of the floorpan where the throttle pedal meets, you can see in some of the other pictures how the depression for your feet in the floor of the car didn't line up with the pedal. Figured I might as well take care of it. I also took the opportunity to mount the throttle pedal lower, so that it was at the height it was designed to be mounted.

Fit, cut and welded the door bars:

#168

Posted 05 January 2010 - 09:45 AM

#169

Posted 11 January 2010 - 06:14 AM

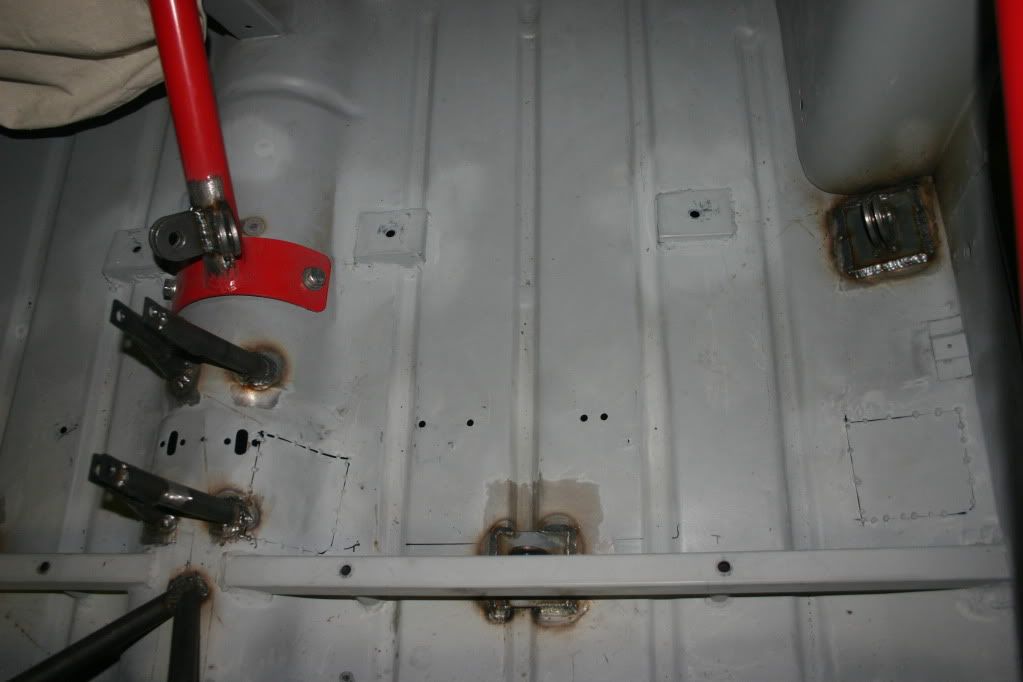

But for now, a quick shot of the completed harness mounts and handbrake mount:

#170

Posted 20 January 2010 - 09:06 AM

Ok Chris, that looks like an awesome job you're doing, i'll be sending my mini over to you on the boat for the same treatment!!! Lol!Thanks guys.

Finished the bottom of the drivers door, needs a little bit of filler since the non-genuine panel doesn't quite have the same profile as the ridge in the door, but it came out pretty good.

I also lowered the edge of the floorpan where the throttle pedal meets, you can see in some of the other pictures how the depression for your feet in the floor of the car didn't line up with the pedal. Figured I might as well take care of it. I also took the opportunity to mount the throttle pedal lower, so that it was at the height it was designed to be mounted.

Fit, cut and welded the door bars:

#171

Posted 22 January 2010 - 08:37 AM

No real interesting updates, stripped the car down to the bare shell and flipped it up on it's side to finish all the welding. The underside has been seam sealed and rubbed down, I'm just waiting for the rain to stop before I partition off the garage and start spraying. Also pulled apart the engine wiring loom, to find that 2 major connectors have been hacked off, as well as a decent length of wiring. Awesome. I've enrolled in a welding class, so I've been putting in work with a TIG machine. Maybe I'll make some parts later...

I'll post pictures when something cool happens.

#172

Posted 29 January 2010 - 06:01 AM

After:

Closeup:

The undercoat is sprayed thicker under the trunk and in the wheel wells.

Subframe:

Parting shot:

#173

Posted 28 March 2010 - 09:15 AM

The car is back on all four wheels and rolling around:

Dash version 2.0 is coming together, courtesy of my dad:

Sweet new Odyssey battery, half the weight and less than half the size of a conventional battery:

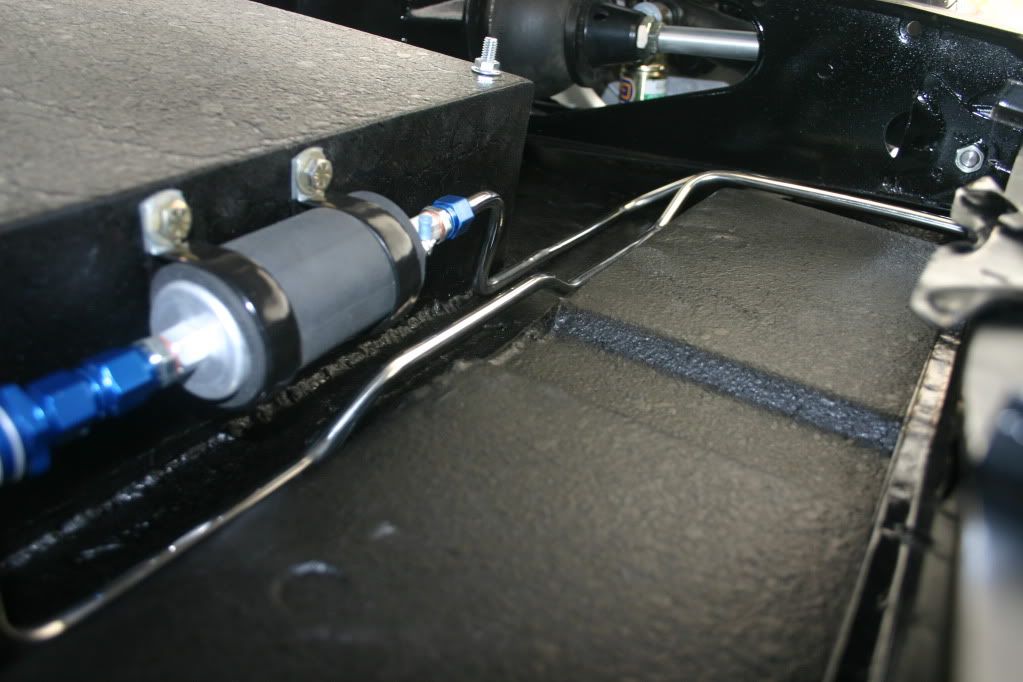

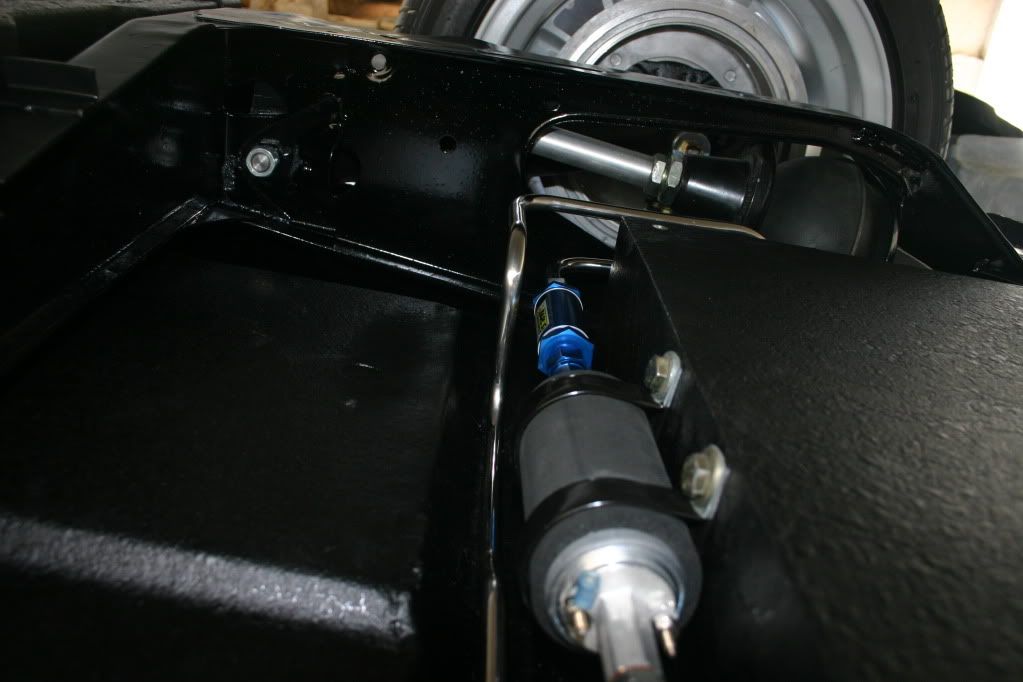

Fuel system 80% plumbed, all stainless AN6 hard lines which I went about polishing:

Muffler scored off of ebay for a price that was impossible to refuse, it's the left hand Yoshimura can from a 2008 R1. Stainless midpipe and carbon can:

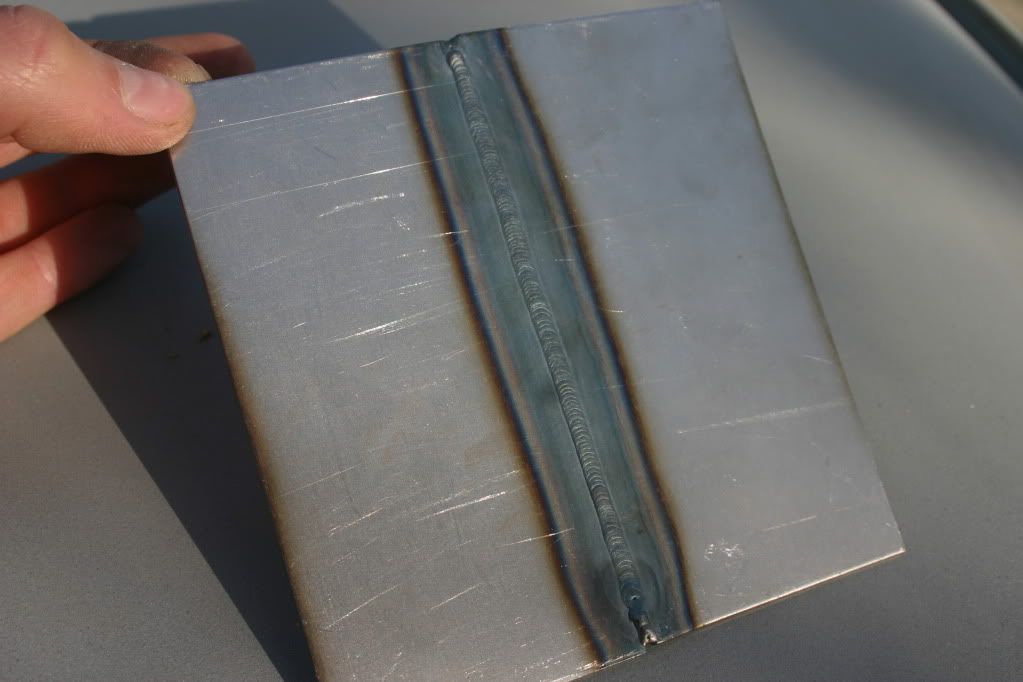

Outside of the mini, I'm trying to become an aerospace welder, and just to show that I'm not slacking, 0.060 sheet butt welded with a 1/16th inch gap between the plates:

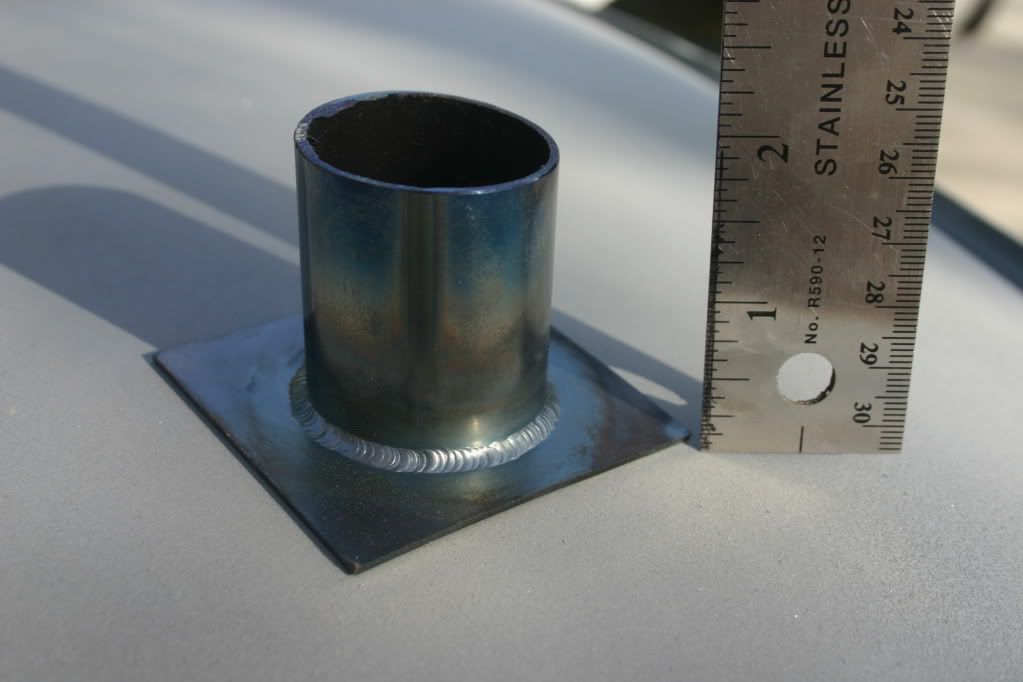

And a little piece I welded on a turntable:

#174

Posted 28 March 2010 - 09:27 AM

Edited by Teapot, 28 March 2010 - 08:44 PM.

#175

Posted 28 March 2010 - 09:30 AM

#176

Posted 28 March 2010 - 07:18 PM

#177

Posted 28 March 2010 - 07:25 PM

#178

Posted 28 March 2010 - 07:46 PM

#179

Posted 29 March 2010 - 10:13 AM

#180

Posted 30 March 2010 - 07:50 PM

I really appreciate all the kind words from you all, it really means a lot to me.

miniQ,The undercoat is from Eastwood, it has to be sprayed in a ton of really thin coats though otherwise it clumps up and pulls apart, leaving cracks.

http://www.eastwood....osol-18-oz.html

PJN, I requested a quote from Hagerty Insurance, which is a classic/modified/exotic car specialty insurance company, and even with me being a young guy it'll be around a grand a year. full coverage, $0 deductible.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users