I have fitted slave cylinder with a slightly different return spring setup than before. Looks much nicer this way.

just got to fit rubber dirt guard,

also welded bracket for return springs to adjustable arm. just need to paint it now.

Posted 24 August 2010 - 05:15 PM

Posted 30 August 2010 - 09:08 AM

Posted 31 August 2010 - 04:02 PM

Posted 30 October 2010 - 05:04 PM

Posted 10 April 2011 - 04:36 PM

Edited by Alburglar, 10 April 2011 - 04:36 PM.

Posted 11 April 2011 - 06:26 PM

Posted 19 April 2011 - 04:26 PM

Posted 19 April 2011 - 04:32 PM

Posted 19 April 2011 - 04:37 PM

Posted 19 April 2011 - 04:39 PM

Edited by Alburglar, 19 April 2011 - 04:43 PM.

Posted 20 April 2011 - 08:50 PM

Posted 21 April 2011 - 07:44 PM

Edited by Alburglar, 21 April 2011 - 07:48 PM.

Posted 21 April 2011 - 10:02 PM

Posted 25 April 2011 - 07:16 PM

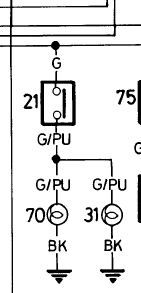

The brake light switch has 2 terminals that are isolated from the switches body,the earth is from the brake lights.

Posted 26 April 2011 - 01:45 PM

Edited by cptkirk, 26 April 2011 - 01:46 PM.

0 members, 1 guests, 0 anonymous users