Monty the Rwd R1 engined tarmac eating Minus

#451

Posted 02 October 2007 - 07:55 AM

#452

Posted 03 October 2007 - 04:07 AM

#453

Posted 11 October 2007 - 05:37 PM

I have cut the allegro lower section to suit my extra low coloumn position and started to make a sleeve for it so I can weld it back together straight.

Then I cut this much off the mini outer column, in order to use the top section of the allegro inner coloumn as it is shorter than the mini inner column. But this meant cutting off the bit of the outer column that holds the bush. Luckily I had a metro (k series) bottom arm poly bush kit lying around, so I made a polybush fit by grinding away a bit of it's circumference, until it fit snug.

#454

Posted 11 October 2007 - 05:42 PM

#455

Posted 11 October 2007 - 05:44 PM

#456

Posted 25 October 2007 - 09:09 PM

How much bigger did you have to make the side windows?

I'll double check but think it was about half inch.

Got my arse in gear and welded and painted the collapsable part og the new column.

#457

Posted 25 October 2007 - 09:30 PM

#458

Posted 26 October 2007 - 10:34 AM

#459

Posted 29 October 2007 - 04:47 PM

#460

Posted 02 November 2007 - 08:48 PM

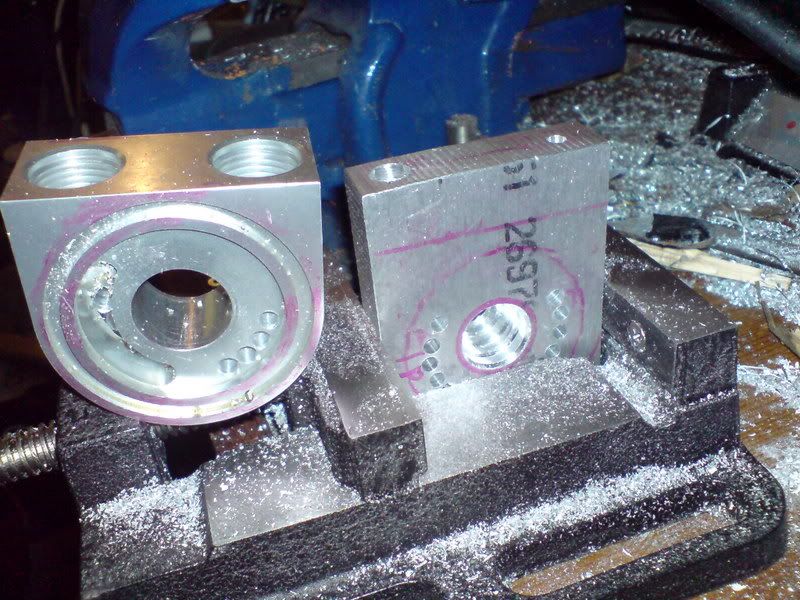

I thought I'd been clever and solved a big problem today. R1 motorbikes don't have any oil pressure or temperature guages, therefore the engines have no senders either. I thought I could solve this problem easy. I got an oil cooler sandwhich plate and drilled straight through it a couple of times so Oil would always be passing through it.

Then fitted a 1/2 to 3/8 bsp (male/female) and a 1/2 to 1/8 bsp (male/male) adapters to it so I could run a mechanical split oil temp and pressure guage via a length of braided hose for the pressure and the standard sender for the temp.

This was great until I realised that the oil filter has been spaced out so far that it touches the exhaust manifold.

I could just tap and thread a 1/8 bsp into this bolt in the water cooled oil cooler and get my oil pressure but then I can't use my split guage,

so I'm gonna bug some mates with acces to machine shops and make up a new sandwhich plate that only has the 3/8 and 1/8 holes in it so I can make it alot thinner.

Edited by Alburglar, 02 November 2007 - 08:49 PM.

#461

Posted 03 November 2007 - 07:19 PM

p.s its coming together now buddy how many hours do you think the column took to build?

Edited by dean_chad, 03 November 2007 - 07:20 PM.

#462

Posted 04 November 2007 - 03:48 PM

#463

Posted 06 November 2007 - 10:22 PM

I had the same problem. I had to turn the plate down so it didnt fowl on the engine rib and also make it thinner, As i was only using 1/8th fittins the block could be turned down a considerable amount.

p.s its coming together now buddy how many hours do you think the column took to build?

Assembling all the bits and bobs took ages, but it didn't take very long to actually put together...

...but I did swear alot when trying to line up the two cut parts of the allegro joint...and then be brave enough to start welding it properly. Lol

#464

Posted 06 November 2007 - 10:31 PM

can you not run a remote filter?

Yeah, but I've already paid out for all my bits now, so wanted to use what I had. Plus, it's one of those jobs that you only ever have to do once, and will look neat.

I did as much as I could with it, but am now farming it out to various friends and relatives. My friend john had the taps at work to thread the 3/8 and 1/8 bsp holes and so that should be done now. Then it's going to my cousin max, as he, hopefully has access to a machine shop to get the recessed bits done.

#465

Posted 18 November 2007 - 05:56 PM

Hopefully there will be enoughe clearance now.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users