Monty the Rwd R1 engined tarmac eating Minus

#421

Posted 06 August 2007 - 01:29 PM

I thought chris was supplying the gripper diff?

Is the bearing carriers easy to remove from the diff as im replacing my diff soon?

Cheers

#422

Posted 07 August 2007 - 08:18 AM

The diff wasn't too taxing to remove, but it is a bit awkward. I removed the offside trailing arm in order to pop the drive shaft out, but you coould try removing the inside bolt and loosening the outside bolt enough to swing the arm away. This might give enough clearance to get the shaft out the hub without removing the whole arm. You can then support the diff (in my case with my knees and some bubble wrap on removal and then I used a ratchet strap either side of the sporcket and over the top roll cage bar to put it back on) and undo the four carrier bolts. When replacing the diff be sure to put the chain on the sprocket BEFORE you bolt it all back together. The bearing carriers are easily removed with a couple of taps from a soft faced mallet.

#423

Posted 08 August 2007 - 04:21 PM

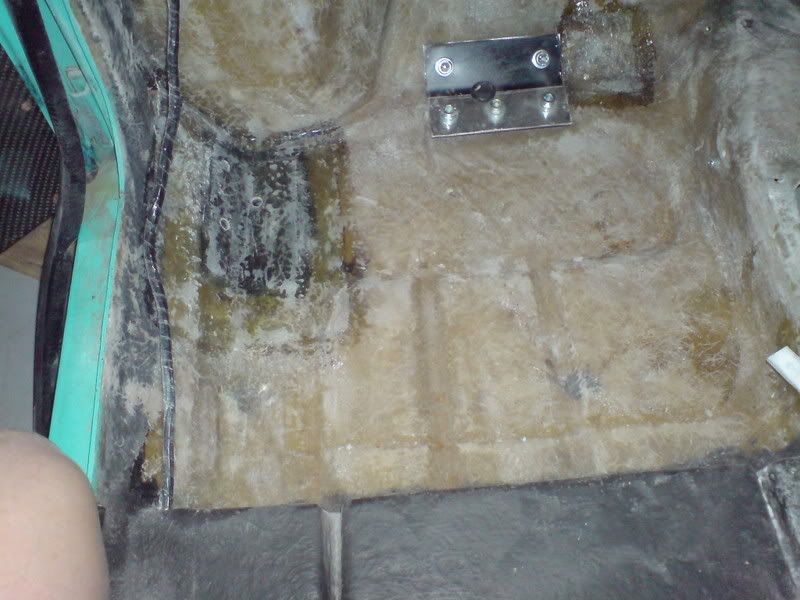

I have finished the restoration of the front floor pans and layed some grp over the painted steel. I then sanded everything, I've just got a few awkward bits around the pedal box to finish ready for paint.

#424

Posted 09 August 2007 - 07:19 PM

Is it going to be ready for the ring Al?? only 20 days YIPPEEEEEEEEEE (kye ehy mother trucker)

#425

Posted 10 August 2007 - 02:23 PM

#426

Posted 13 August 2007 - 09:20 PM

#427

Posted 21 August 2007 - 06:18 PM

And I have fitted the speed sensor for the digi dash. The sensor picks up a signal from a magnet passing it, the magnet is bonded to what's left of the front drive shaft, with a chemical metal type product.

#428

Posted 23 August 2007 - 11:07 PM

#429

Posted 24 August 2007 - 11:39 PM

#430

Posted 25 August 2007 - 02:04 AM

#431

Posted 12 September 2007 - 12:20 AM

It is surplus now so I've binned it...

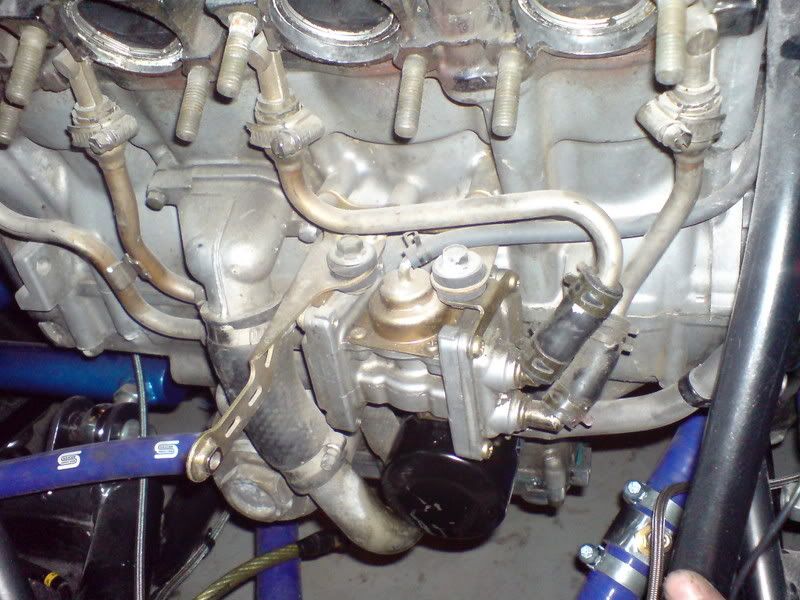

...but it has left these little fittings next to each exhaust port, question is - Has anyone come up with a neat way to blank these off with out re-tapping the hole in order to block off with a bolt?

- Are the fittings an interference fit? ie Willl they just pull out of the head?

Edited by Alburglar, 12 September 2007 - 12:28 AM.

#432

Posted 12 September 2007 - 12:26 AM

... I've managed to make a neat job of the water pipes, which is important as they run pretty close to the exhaust manifold.

and fitted a water temp sender

#433

Posted 12 September 2007 - 12:46 AM

like where the line for the clutch slave cylinder runs under the steering rack.

I also made up a bracket with riv nuts in as I couldn't get a spanner on here either

#434

Posted 12 September 2007 - 12:47 AM

Edited by Alburglar, 12 September 2007 - 11:14 AM.

#435

Posted 12 September 2007 - 03:03 AM

The holes left are a perfect fit for a M10 tap. Tap them out with a vacuum for the swarf and insert M10 x 10 grub screws with locktight.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users