Hi

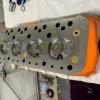

I have been practising head work on, what was sold as scrap, a 12G940 cylinder head, however since cleaning it up, it seems to be free of the normal damaged that would declare a head scrap, e.g. cracks between the valve seats etc. It does have a couple cracks at the bases of the rocker stud holes though.

I am doing this myself with minimal tools, I have just picked up a SH Neway Cutter Set, which came with a Neway 285 - 46 degree cutter and a 7mm adjustable guide, among some other bits.

I have access to a Warco Hobby Lathe and Pillar Drill.

I also have a DTI gauge and Magnetic Stand (Used for setting the engine timing)

I now need some advice in a couple of things:

Valve Seat cutting:

1. How do you ensure that the valve seats are at the same height?

2. Can you use a hand cutter in a battery powered drill (without a flexi drive)?

3. Can you use a hand cutter in a Pillar Drill?

4. If using a pillar drill, could I use a DTI gauge to get the seats at the correct heights

5. What tooling could I use to enlarge to ports to use 35.6mm inlets as opposed to 33.3mm valves?

What tooling could I use to cut a recess around the valve seat area to a specific height, this is to use as a guideline when raising the chamber roof? (similar to the recess that you see around the valve seat on a stock head.

Also:

6. If installing manganese bronze valve guides, where can I get the correct reamer to ensure the correct tolerance with the valve stems? Are these turned by hand or can I use the TailStock chuck on the lathe?

7. Without a hydraulic press, what is the best way of installing valve guides and getting the correct height?

Many thanks