Back at it today after not having much motivation to do much.

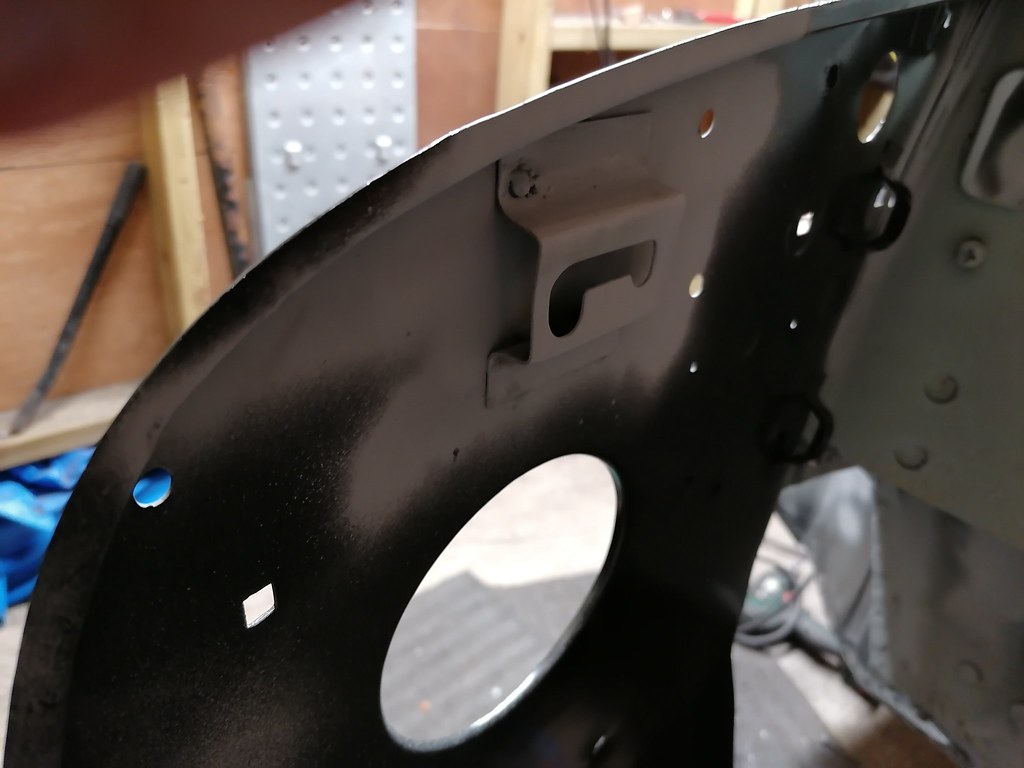

Decided to try and get inner wing full fitted, but first had to close off end of bulkhead cross member.

Once that was done I offered up the inner wing and clamped it all in position. Then scribed the inside to mark where I needed to drill for plug welds, the got on with drilling.

Didn't feel right drilling into a new panel

I went 8mm for the holes, but think I could have done them 6mm, would have been quicker to fill.

Took it nice and slow with the dressing down as to not put too much heat into the welds, a few pin holes here and there but overall I'm happy, feels like it's fully secured. Ran out of time to dress off the last of the welds, so cleaned them up and gave them a coat of zinc primer til I can finish them.

I took a look at the engine during the week, took off clutch cover, lots and lots of clutch dust build up, lots of crud lying at the bottom of the housing too so will need a good clear out before digging deeper. Stripped down the head ready for cleaning, very pitted around thermostat housing, I have a spare head of the same CAM4810 so will use that as it looks in better condition.

Valves have F and H stamped on them, any ideas?