So the beam ends weren't sitting flush with the heel board. But on closer inspection, the heel board angles outward on the top section of the flat panel. I think you can make out the gap. I'll take the beam out and "reprofile" the upper middle mounts so they match the angle to the heel board. The main mounts at the left right ends of the beam should then pull in tight.

Heel board drilled for the subframe. Took a while to satisfy myself it was lined up. An OCD trigger as these shells are not square. Then a little scuffing, wipe with degreaser then a dust of etch them some left over white primer. Top coat later this week

Fabricating the feet for the roll hoop/spaceframe and doing some fit and finish to the heel board surface as it was a bit uneven. The feet pick up the rear subframe mounting bolts that come through the heel board.

Hoop feet (which also double as strengthening plates for the rear subframe finally in place. Took a while to get them to sit square and level as the grp was uneven (as I'd repaired and rebuilt those areas). Final job will be to lay in a thin layer of CSM and bolt them in, so the metal has a perfectly flat bed.

Thin first coat rolled on tonight. I'll leave this for a few weeks then give it another coat.

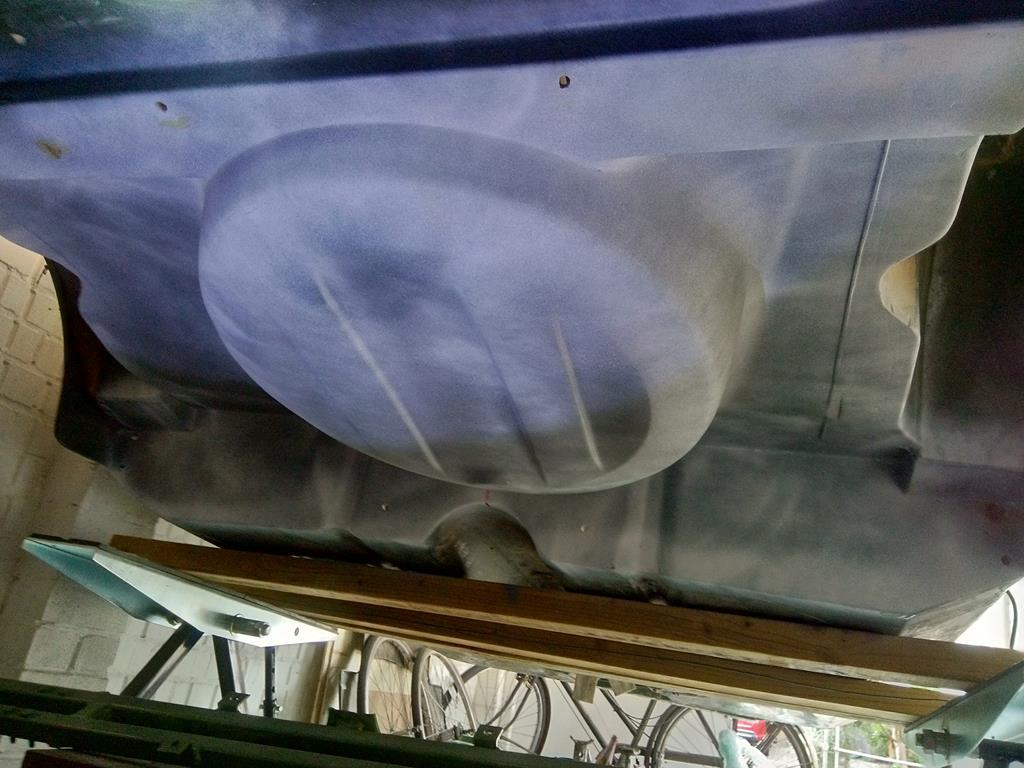

Needed to put some stiffeners in the rear panel as its flexes in the middle. Fabbed a crude mould with a quids worth of offcuts from my local hardware shop. cover it in wide sellotape and coat on some carnuba wax to help it release. 3 layers of glass tissue get one these. Marked up the panel and glued them in with epoxy then will lay over the whole panel some woven roving and CSM. For stiffening but also to make that panel nicer to look at as its got some naff glass work from a PO and also all the repair work where i had to patch up the holes in the panel.

Dug out the bracketry from the powdercoating box and cleaned up the thread to fit them to the subframe. Next up will be refurbing the radius arms and getting those bolted to the subrame. This is so i can get the frame back on the car and bolt up the rear coilovers to check the coilover to chassis clearance. the GAX coilovers have an offset top pin mount but the springs can run close to the inner arch. With the coilover in place, I can fab the spaceframe/rollhoop which i'll send off for seam welding.

Had to use the modified slide puller to knock out the inner needle bearing which I'd left in when sent for powder coating. New radius arm pin kit fitted, but as this is a custom race arm, it uses a needle bearing at both ends for quick swaps. Normal mini arms have a needle bearing at one end and solid bronze surface Bush at the other (which needs to be reamed)

Handbrake quadrant refitted with a new stainless long neck bolt.

Drivers radius arm bolted in so the coilover could be fitted. Confirmed that the coilover, using the existing mounting hole, is not perfectly vertical. Top mounting hole will need to move inwards so I'll have to fabricate some grp box section to turret the arches.

This is the coilover topmount from inside the cabin. Bolted in using the existing hole, which confirms my suspicion that the hole is too far out. Hole needs to move about 10mm to the right. But the coilover will be right into the arch skin.

After reviewing the other rear arch, I've decided it doesn't need turreting. The drivers side is slightly out of tolerance (as you expect for a grp shell). I've redrilled the arches for the damper top pin and they run close (just like a steel mini shell), just that the drivers side is a few mm tighter. That can be sorted with a bit of grinding back (seems that has already been done by a PO)

So first steps was to add a few layers of csm and woven on the inside/cabin side of the arches , just to beef up the arches. Then make the steel brackets for the spaceframe.

My small welder is struggling with the thick steel so hoping the tacks will hold

Rear hubs going back together.