Camshaft End Thrust/play

#1

Posted 24 February 2018 - 05:27 PM

Weve had to rebuild the engine again and were at the point of measuring the camshaft end play.

Weve got an 848 block with a PIPER BP255 cam (with a slot drive oil pump) and a new thrust plate and new 6 hole cam sprocket.

When we measure the end float with a DTI its 0.44mm and the spec says it should be 0.076mm to 0.178mm what can we do to minimise what weve got?

Cheers for any help or suggestions,

Ben

#2

Posted 24 February 2018 - 06:10 PM

#3

Posted 24 February 2018 - 06:32 PM

If the Cam is ground correctly, as long as there's at least 0.004", it doesn't other wise matter.

#4

Posted 24 February 2018 - 07:14 PM

Nut torqued up? Needs to be

Torqued to 70 lb ft.

#5

Posted 24 February 2018 - 07:16 PM

If the Cam is ground correctly, as long as there's at least 0.004", it doesn't other wise matter.

So were ok?

#6

Posted 24 February 2018 - 07:40 PM

Is the cam wheel seating properly onto end of camshaft, and is new thrust plate same thickness as original?

#7

Posted 24 February 2018 - 08:27 PM

If the Cam is ground correctly, as long as there's at least 0.004", it doesn't other wise matter.

So were ok?

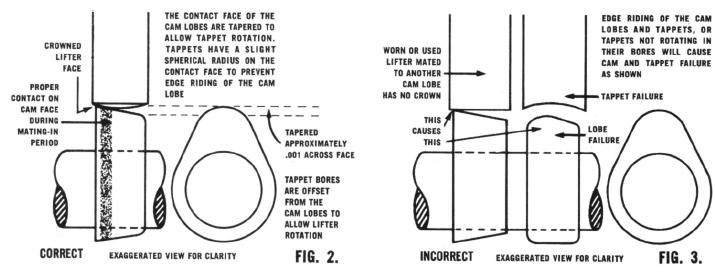

Read up on post 39 in this thread

http://www.theminifo...am lobe taper

#8

Posted 25 February 2018 - 12:08 AM

Ac

#9

Posted 25 February 2018 - 10:13 AM

I think Moke is alluding to the taper ground onto the lobes ( or should be anyway!) this along with a "crown" ( radius of about 40" crond on the face of the follower) causes the follower to rotate so wear is distributed.

personally i would be looking to keep the endfloat down to near tolerance it its easy to do.

Edited by mini13, 25 February 2018 - 10:13 AM.

#10

Posted 25 February 2018 - 01:28 PM

Edited by Sprocket, 25 February 2018 - 01:30 PM.

#11

Posted 25 February 2018 - 05:53 PM

Excess camshaft endfloat could also affect timing chain alignment, I think the chainwheels are meant to be exactly in line (to within a few thou).

Seem to recall that in the 60's the factory set up the chainwheel alignment on the works engines by machining the camshaft sprocket, eliminating the shim washers on the crank.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users