This is another one of those areas where I've made changes and I wanted to compare with the standard to setup to see if there's anything that needs remedying. What I found surprised me quite a bit.

Previously when I was running standard steel wheels on 8.4" disk brakes at the front and 1" spacer drums at the rear I always noticed that the threads in the wheel nut do not engage entirely with the stud as the stud isn't long enough. It never concerned me as obviously it was enough or the wheels would have fallen off the car long ago.

I'm changing over to 10" Exacton wheels which use a different style of nut and I wondered what the thread engagement was like with these nuts as opposed to the stock steels and their nuts.

Before viewing what I found it's worth noting that I have converted to Cooper 'S' brakes on the front and as such I'm using the studs that came fitted to the 7.5" disks.

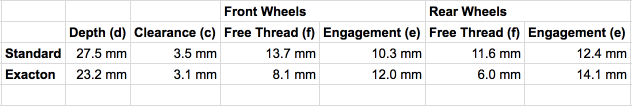

Here are my findings:

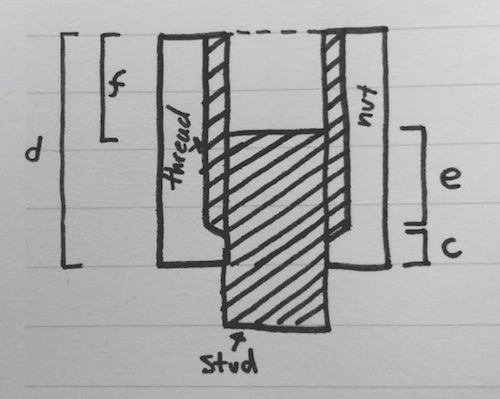

Here is a diagram to help describe each measurement:

Now is it just me or does that seem like quite a small amount of thread engagement?

I'm imagining it must be fine as with the new nuts the engagement front and back is better than the old nuts on the rear which is the standard fitment from the factory.

Wheel Nut Thread Engagement

#1

Posted 06 July 2017 - 01:35 PM

#2

Posted 06 July 2017 - 02:18 PM

A good general rule for all types of threaded fixings is that the minimum depth of engagement should be 1.5 x bolt diameter.

#3

Posted 06 July 2017 - 03:30 PM

Without going into it too much, you basically need enough thread that the stud will snap before the threads strip.

Using the link will show you the calculations required for this (http://www.roymech.c...read_Calcs.html).

They basically say that 0.8x the screw diameter is sufficient to ensure the bolt/ stud will be the weakest link, and this is how most standard nuts are designed (M10 nuts are 8mm thick, M5 are 4mm etc.)

On tapped holes the recommendation is 1.5x the diameter as not all threads will be properly formed. If one material is weaker than the other then you shouldn't use these rules of thumb.

Mini wheel studs/ nuts are 3/8" which is ~9.5mm, so you would be looking for a minimum of around 8mm thread engagement, but obviously is it better to err on the side of caution with things like this but I think the 10.3mm & 12mm engagement you have should be fine as this is an extra two and four threads respectively.

http://www.roymech.c...read_Calcs.html

#4

Posted 06 July 2017 - 07:18 PM

as you may know there are only two short lengths listed for the Mini and this length may not correspond with the amount of stud out of the mounting face.

there are others.

#5

Posted 07 July 2017 - 06:32 PM

A good general rule for all types of threaded fixings is that the minimum depth of engagement should be 1.5 x bolt diameter.

The wheel studs and nuts are mission critical and also highly stressed.

3/8 UNF, torqued up to 45 lb-ft, that's the same size and torque as cylinder head nuts.

#6

Posted 11 July 2017 - 09:40 AM

Basically you need to find out all that you can about the nuts. Also it us normal to have any thread protrude through its nut by at least one full turn, mostly to ensure that the nut is engaging only on fully formed threads.

I would strongly recommend longer studs from the most reputable supplier that you can find.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users