How Do I Make Wired Edges?

Started by

Frost Auto

, Feb 09 2017 07:21 AM

5 replies to this topic

#1

Posted 09 February 2017 - 07:21 AM

Step 1

Mark out edge to be wired, with approx 8mm extra for making the wired edge. Use G104 Aviation Snips to cut to the 8mm line.

Step 2

Using Swage fit the jenny wheels to throw up an edge along the marked line (about 45 degrees).

Step 3

Use the wiring wheels to form a U shape along the crease previously formed, the work piece will have to be tipped to so as to come down the face of the top wheel.

Step 4

Insert the wire in the U and trap it by using a hammer on the open edge at approx 150 mm intervals.

Step 5

Put the closing wheels on the machine and set the gauge approx 6mm behind the top wheel.

Step 6

Run along the length of the wired edge closing it sufficiently to securely trap the wire all the length.

Step 7

Set the closing wheel to one thickness of metal (about 1mm) and run down the edge again to give a full length, even finish.

#2

Posted 09 February 2017 - 09:08 AM

Could you add some photos? Just a suggestion.

#3

Posted 09 February 2017 - 10:30 AM

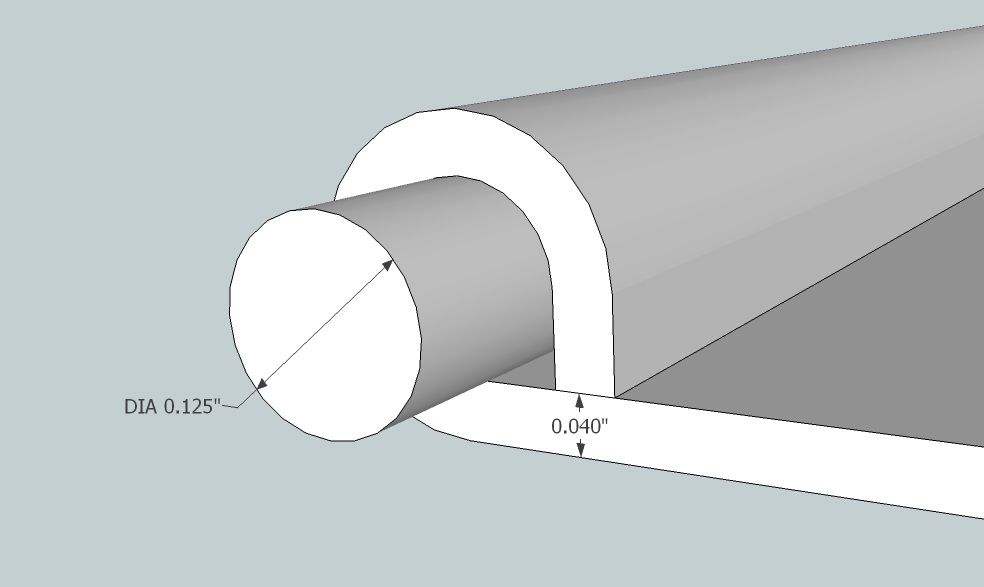

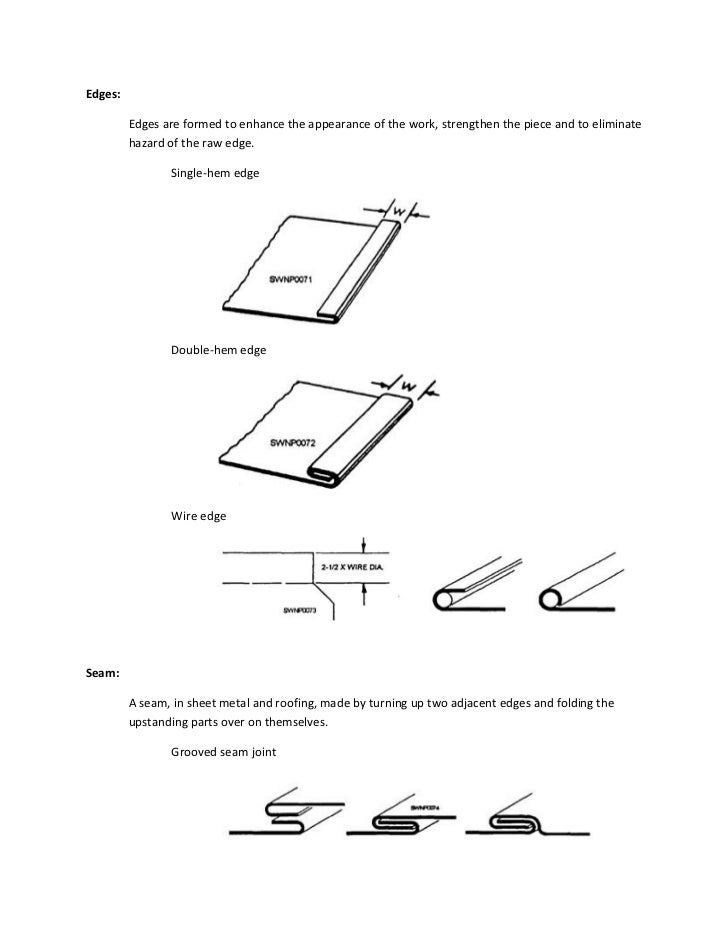

Erm......What's a wired edge?

#4

Posted 09 February 2017 - 10:40 AM

The edge of the sheet metal is formed around a length of wire to strengthen it - think of the wing edges on an old 30's car with big flowing wings.

#5

Posted 09 February 2017 - 11:01 AM

Something like this:

It adds strength to the edge of a panel, plus it looks quite nice if done properly.

#6

Posted 09 February 2017 - 12:34 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users