Hi, Just wondered the best way to get the old core plugs out of the 1275 A+ metro block im rebuilding for my mini? Thanks Martin.

Getting Old Core Plugs Out?

#1

Posted 28 October 2016 - 05:56 PM

#2

Posted 28 October 2016 - 06:04 PM

Clean off any paint/rust/cr*p etc first though!

#3

Posted 28 October 2016 - 06:47 PM

To remove the oil gallery core plugs you just drill a small hole in the centre, screw a self-tapping screw in and prise it put with a pair of long-nose pliars.

Make sure you clean out all the DGS in the galleries very thoroughly before fitting the new ones and use a bit of thread-lock when fitting them.

#4

Posted 28 October 2016 - 08:28 PM

Thank you both for that, is it really important to remove the oil gallery plugs, I'm a bit worried they might leak afterwards, whats the best way to refit both types, water and oil? Martin.

#5

Posted 28 October 2016 - 08:38 PM

The gallery core plugs don't leak if installed correctly.

#6

Posted 28 October 2016 - 08:40 PM

Many Thanks.

#7

Posted 28 October 2016 - 09:56 PM

I put the plugs into the freezer the night before to reduce them down in size a touch.

Edited by DJS911, 28 October 2016 - 09:56 PM.

#8

Posted 29 October 2016 - 10:46 AM

Many thanks to all. Martin.

#9

Posted 29 October 2016 - 08:38 PM

I use loctite on all the plugs to seal them.

For the Core Plugs, there's different ways of getting them out depending on if you have a small bore block or a big bore one.

This is because the small bore blocks use a lens type plug that has a seat machined in to the block, where as a big bore block uses a cup type plug that fits to a machined bore in the block with no seat. The same technique that is used on the Lens type plugs can be used on the Cup types and that is to fit up the slide hammer using a self drilling screw nearer the centre of the plug, then you won't damage the seat that's machined in to the block.

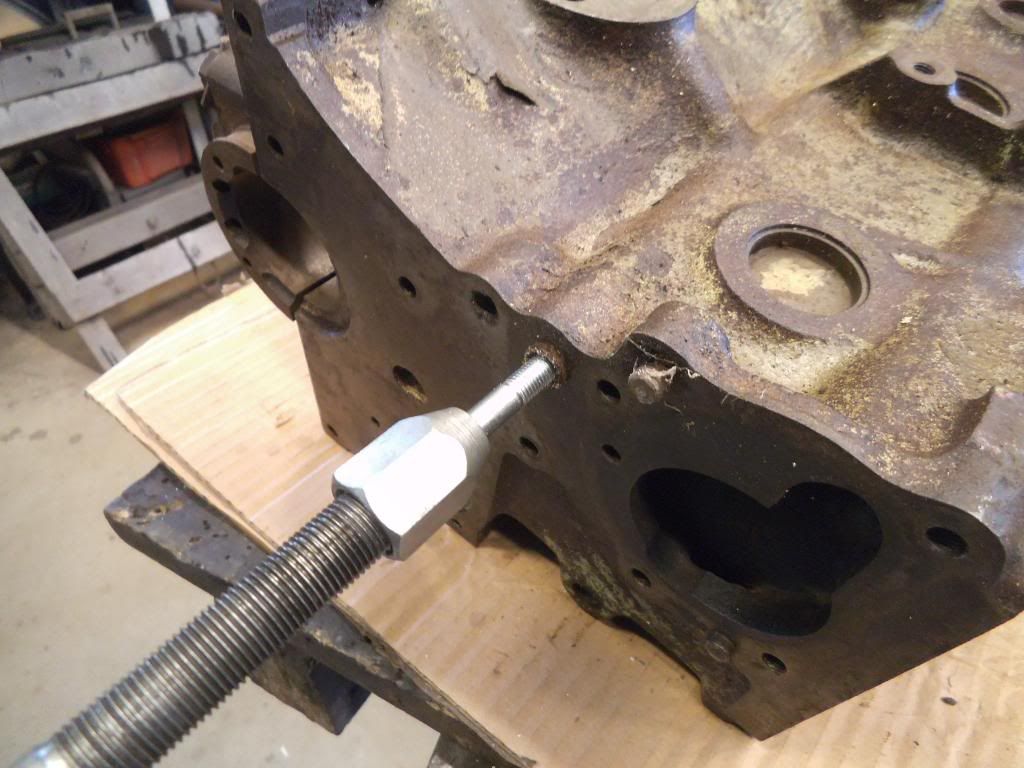

To get the Main Gallery Oil Plugs out, first, I drill one of them

I would not advocate trying to drill them all the way out as if you nick the drilling, you'll never get it to seal.

Then tap a thread it

Fit the slide hammer

A couple of hits

and it's out

then drop an 8 mm rod down that hole (I use some all thread as that's what I have handy)

a couple of taps

and the other plug is out

There's also a couple of smaller plugs in the block, one's in the front and the other is in the sump rail. You can pull them, though I don't always as the oil that passes through these is unfiltered in any case. I do check how much crud is in there and if I'm suspect of them, I will pull them for cleaning. These are in the Oil Pressure Relief Valve Circuit and allow Oil from behind the Valve to drain, otherwise the Valve will hydraulic lock. A word of caution when refitting these plugs (if you do pull them), fit the one from the front of the block first and don't drive it in too far. You can check by looking up the other plug hole that's in the sump rail to see if it's all clear or driven too far. The drilling from the front isn't deep, so very easy to over do it. Then fit the plug that goes in the sump rail.

You should also pull the Oil Pressure Relief Valve Seat from the block too.

#10

Posted 29 October 2016 - 08:59 PM

The oil gallerie plugs should be removed by drilling and tapping and the use of a slide hammer

image.jpg 58.93K

3 downloads

image.jpg 58.93K

3 downloads

#11

Posted 30 October 2016 - 08:39 AM

It is more important to clean out the oil galleries than almost anywhere else.

I got some gun cleaning brushes for this

#12

Posted 30 October 2016 - 10:48 PM

The solid-type oil gallery plugs have been NLA for a long time in the UK. The replacement is the pressed disc type which are no-where near as good. I had thought of getting some turned up and I reckon aluminium bar would turn down well. Diameter is a nominal 1/2", but I need to measure the actual size using a block with the existing plugs removed. They need to be a good taper interference fit sealed with Loctite Bearing Lock.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users