It's taken 18 months or so from conception to completion but it's finished, Project Airbox is go!

When I first got my car it had one of those K&N 'noise intensifier' cone filters on. That soon went and was replaced by a Pipercross filter sock and a Pipercross substack, the one you can see in the left of the pic ^^^. It was better. Until the cam came 'on song' and it made a really noisy 'thwaaarp' kinda din! ![]()

The next plan was to make an airbox, a more modern way of inlet that would take the intake away from pointing straight at the cabin.

Many cups of tea and thinking went on then. We thought about vacuum moulding some plastic, but A: we weren't sure about how it'd handle the exhaust temps sitting right above the manifold and B: we're not used to using plastic; we do know aluminium so that was that. Thanks to Chris (Moke Spider) at this point who went to great lengths to explain how we'd mould it in plastic.

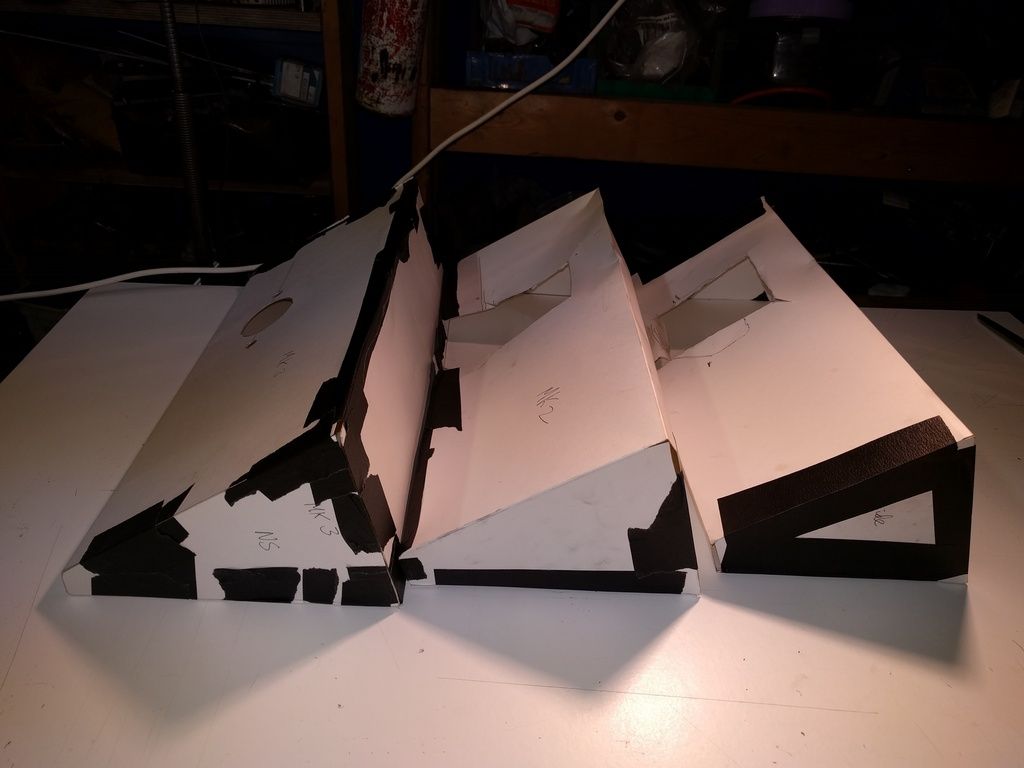

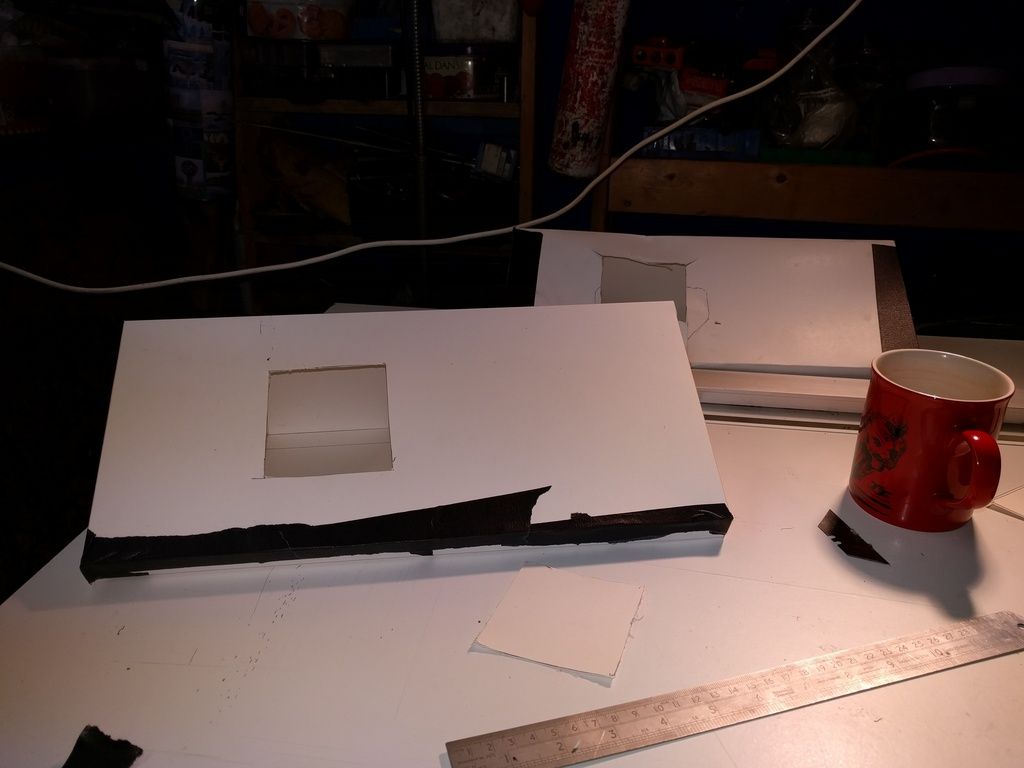

A number of cardboard templates we're knocked up to find roughly the right size:

And tried in place:

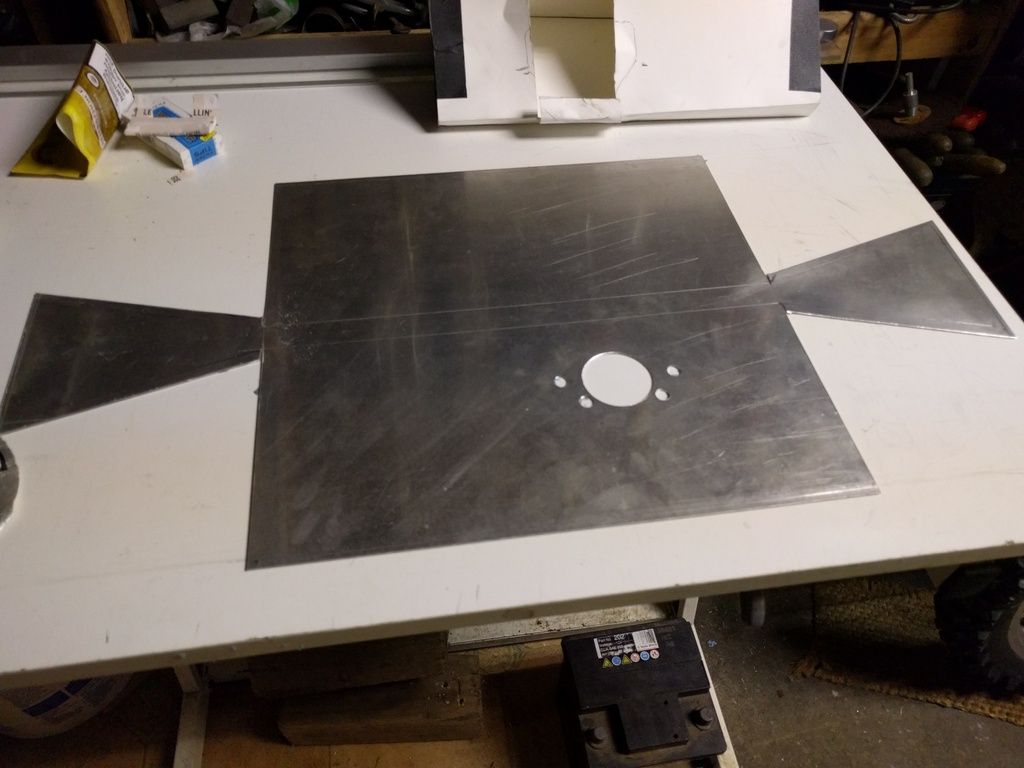

Once we'd decided on a size that would fit in we cut it out of a 1.6mm sheet of ally:

Folded it up:

We'd thought about riveting it but came to the conclusion that peening blind rivets over in the tight confines of the bottom corners would be next to impossible so it had to be bolted up. We 'tacked it together with some self-tappers at this stage. I went to one of my favourite websites, Accuscrew and found some suitable M3 button screws for the finished article.

It was now that we tried it for size. It was too big to get in! Balls! Professor Pete took it apart overnight, trimmed it down and rebuilt it "next time Tim, I'll do the ![]() measuring"

measuring" ![]() He also added a crease in the lid to lessen the vibrations.

He also added a crease in the lid to lessen the vibrations.

It was a goer:

I had a big ole K&N my old Dad used to use on his beloved Villiers karts so I had to use it, he'd have liked that. We thought about using it on the front of the airbox like the above pic but A: It was right in the hot air off the exhaust and B: we wanted to maximise the volume so I found some 60mm ID ducting from Autosiliconhoses. (Strangely only available on their eBay shop?)

It ended up at about 3.5 litres volume including the ducting.

I located some stainless steel clips and three or four coats of Simoniz Tough Black were applied:

Job's a good 'un:

We were even able to squeeze in the 3D-printed bellmouth we did nearly 2 years ago:

The result is good, the car is a lump quieter in the cabin than it was. I've no idea yet if the fueling might have been affected, I'll have to do a session of plug chops to check that out for sure, but it 'feels' fine.