Been in the auto industry a bit, worked at a restoration shop for a few years here in the states.

This is my second mini, had a 69 about 5-6 years ago before I moved into the 4x4 realm. Built a 69 bronco, 85 Gelandewagen, 74 FJ40, 84 FJ60, and now I'm back into a 1974 Leyland 1275gt that I'm turning into my track/rally rig.

Initially when I bought her she had issues backfiring and not wanting to go past 2500-3k in any gear. Figured it was a fuel issue and I knew I was going to refresh a bunch of components so I put it on the back burner.

Gutted and painted the car, put in a cage, new seats, poly Windows, etc. and now I'm trying to get her road worthy.

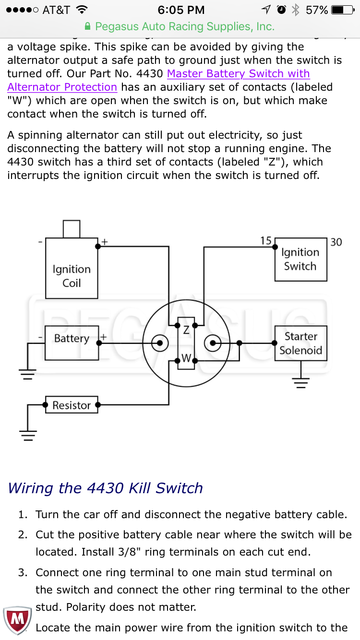

Put in a 45d electric red rotor (vac adv) sold through minimania (model psd5), new coil/plugs/wires.

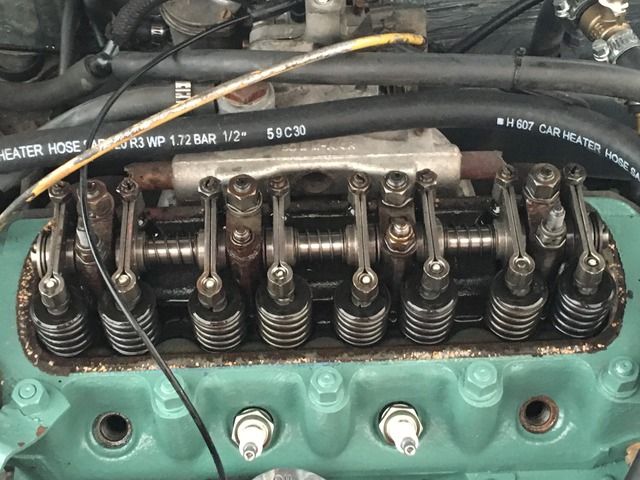

Did a quick check to make sure #1 was at top by removing the plugs and sticking a pencil in the hole till it went all the way up before heading back down. Installed the dizzy (only fits in one way due to the diff slots) and the rotor was pointing at #1 at roughly the 2oclock position.

The car is just as it was before I tore her apart. Starts and idles just fine, can sit forever at idle without overheating (added a heater core front mount rad :) ).

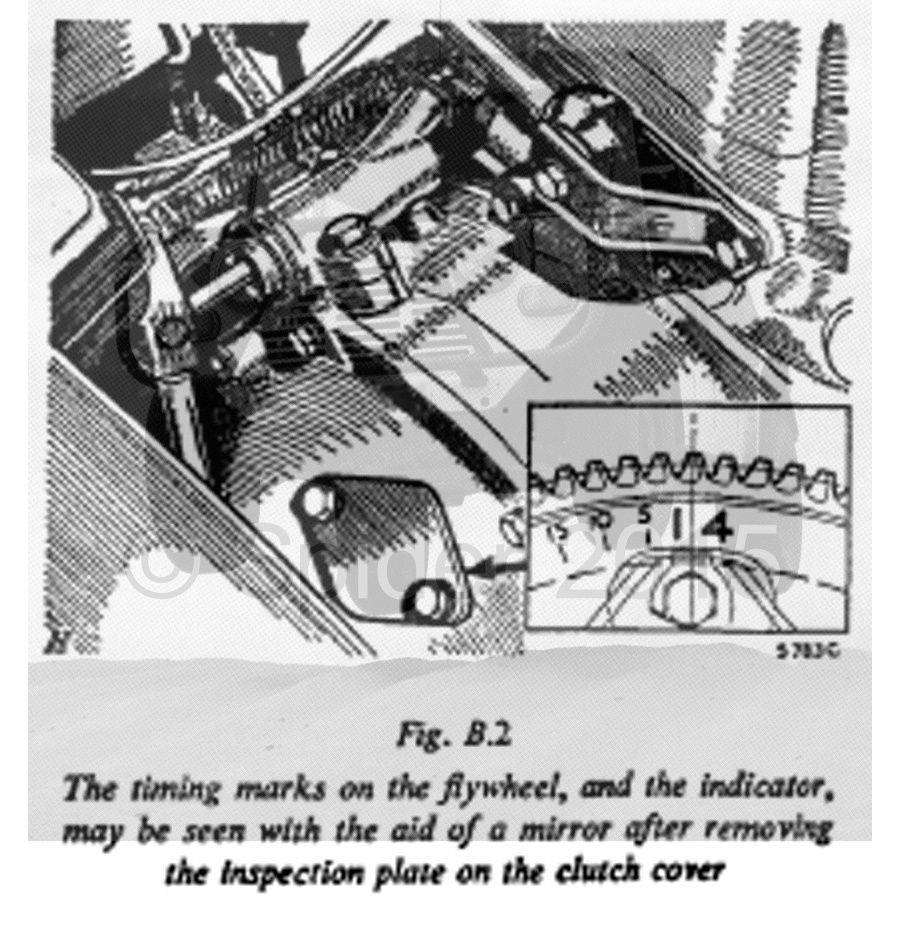

I got her on the road it and it still had the same issue. I need to point out that I have a timing light but my car doesn't have the timing tab so I did it by ear the best I could.

I removed the carb, cleaned her out and assembled with anew filter, gaskets, and changed the original filter to a cone type (SU carb).

Still the same outcome. I checked the mixture ratio by pushing up the lifting pin on the underside of the dash pot and found that the mix was lean cause at full lift the engine wanted to die. Lowered the nut till a small lift would raise the rpm then level out.

Hesitation and sputtering seemed to get a bit better. I can feather the gas and push pass the dead zone and every now and then the engine will climb like it's supposed too.

This weekend I plan to remove the rocker cover and make sure the valves and #1/4 are truly where they are supposed to be.

But I need pointers basically a step by step on things I might be overlooking.

Haven't checked to see if I have an inspection cover but in the event that I do what do I check? What do I lineup? Where do I put a makeshift tab and what do I set my gun too?

I've tried 15/40, marvels mystery oil, 20/50 in the dash pot with the same outcome.

Would really like to get her on the road sometime soon.

Thanks in advance!!