Crankshaft End Float Measurement

#1

Posted 27 August 2016 - 02:04 PM

Just started to build my 1275 +60 engine, got to the point where we are measuring float end movement.

We think we are reading the dial right and we have 0.2mm which changes to around 8thou.

So we need +3 washers to bring it to 5thou

Hopefully the video works below-

#3

Posted 27 August 2016 - 02:35 PM

#4

Posted 27 August 2016 - 02:41 PM

#5

Posted 27 August 2016 - 03:37 PM

During use this may well increase slightly, but normally the bearings take the wear. Over time it is necessary to fit thicker bearings, usually after a re-grinning of the thrust faves on the crankshaft.

Always aim to start within the stated figures.

#6

Posted 27 August 2016 - 04:47 PM

#7

Posted 27 August 2016 - 07:35 PM

#8

Posted 27 August 2016 - 07:54 PM

#9

Posted 27 August 2016 - 07:54 PM

Give us a ring on Tuesday morning at Somerford Mini.

#10

Posted 27 August 2016 - 08:38 PM

#11

Posted 27 August 2016 - 09:27 PM

If you have, say, 7 thou end float, you use a pair of +0.003" which would give 1 thou which is below specification. What you do is to linish a bit off the back face of one pair - that's off the steel backing side - until, after repeated trial fits, you have 0.002" float. Actually just under 0.002" float is OK, but not below 0.0015".

With a larger end float, even with a pair of +0.003" both sides, you can buy a couple of pairs of +0.030" and have a machine shop machine metal from the steel backing until the float is correct. Just make sue the measuring is done accurately.

It's the way these thrust bearing wear that means you should never start the engine, especially from cold, with the clutch pushed down, as there can be momentary oil starvation if you do.

#12

Posted 27 August 2016 - 09:44 PM

The oversize Thrusts aren't per side but in total. So, those marked as +0.003" sets will only reduce the Total Thrust by 0.003", or put another way are 0.0015" per side. In this regards, I'll point to Main & Big End Bearings, these are sized on the Diameter (ie, total) not per side.

In your case, with what you've measured (sorry, the video wasn't clear enough here) at 0.2 mm which I work out as you have to the 0.008". Fitting a pair of 0.003" thrusts will bring that down to 0.005".

I know what the workshop manual states in regards to crank end float and respectfully note other's experience, in particular Cooperman, but I've found even at 0.003" they are too tight. I generally aim for 0.004" to 0.005" for a road engine. If you're not sure, I'll also add here that there's no consequence from adding a couple of thou here, but there will be consequences if it's even as much as 0.001" too tight.

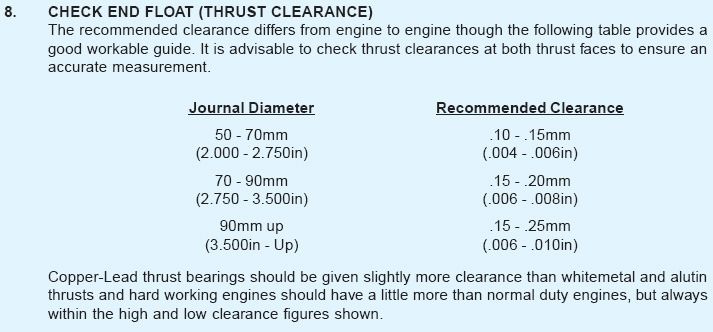

Even ACL's (a bearing manufacturer) advice points to this;-

<Edit: moved to following page >

Edited by Moke Spider, 30 August 2016 - 11:03 PM.

#13

Posted 27 August 2016 - 10:33 PM

Did you use a new set of standard thrusts to measure your end float?

#14

Posted 27 August 2016 - 11:53 PM

Did you use a new set of standard thrusts to measure your end float?

Yes new pair

#15

Posted 27 August 2016 - 11:54 PM

Mini Spares part number AEW2136-003

They are the ones I was hoping to buy, but they are out of stock.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users