Primary Gear Front Bush And Damaged Crank

#1

Posted 22 May 2016 - 07:47 PM

Changed the primary gear front and rear bushes, had ordered the MS floating front one but received a press-fit version. Once both fitted took elaborate precautions to machine them concentrically and believed the tolerances were OK.

However progressively worsening rattle has led me to strip everything and after 1.500km I find I have a front bush with no bronze left, a crank that has been rendered rough and undersized, and enough slop to drive a coach and horses through. Top hat rear bush is of course worn too but otherwise looks to have done its job and the crank is OK there.

It's a wonder the thing ran at all ............

Question please : is the crank scrap, or can It be remachined and a specific front bush made to cope with the new diameter ? : any addresses in the UK whom I could go to ? : what went wrong ? road use and nothing violent : is lubrification indeed just splash ? I did soak it 24h In engine oil before assembly.

Steep learning curve here.

#3

Posted 23 May 2016 - 05:37 PM

Hi That Man In Pont St Vincent !

Yes, I've just read the thread and am reassured to not be the only one, albeit I seem to have inflicted this on myself ...........

I'll be following this exchange closely.

http://www.deva.de/e...al/where-to-use

They supply the stuff as machinable blanks so at least we can make one-offs.

http://www.deva.de/e...tal/basic-forms

#4

Posted 23 May 2016 - 08:01 PM

Any idea who supplied rover with these bushes ?

Pete

Edited by pete l, 23 May 2016 - 08:01 PM.

#5

Posted 23 May 2016 - 08:46 PM

Do you know where the bush came from?

Also, when machining the bush after fitting, what did the swarf look like as it came off the bush? ie, was it '6's and 9's', long twisted strings or powder?

Could you put some photos up of your crank and bushes?

In the case of the damaged rank that's currently on my bench, I'm having that ground and will now likely be making my own DEVA bushes, so for this one, it'll be sized to suit, which is how I go about all of them, just this one will be considerably undersized from standard.

Edited by Moke Spider, 23 May 2016 - 08:53 PM.

#6

Posted 24 May 2016 - 06:29 AM

So it needed pressing in.

Machining it gave curly swarf and nothing like any sintered bearing material would produce.

I am still prepared to entertain the idea that I fitted it too tight, although I did use Graphogen and oil upon assembly.

Upon disassembly the Graphogen seemed to have been useful only as a glue for the swarf generated by the pick-up of the bush on the crank, and after 1500km I was surprised to see so little evidence of engine oil ever finding its way in.

Did you find a suitable blank from DEVA that provides a good starting point for bushes ?

#7

Posted 25 May 2016 - 12:14 AM

For a Bronze material to pick up on the crank tail it would have to contain aluminium or a lot of tin, which is of interest. Ideally it should have a reddy orange tinge to the material.

What lubricant did you use on the tail under the bushes ? ie to lubricate the 2 bushes ?

#8

Posted 25 May 2016 - 07:07 AM

i read:

" I did use Graphogen and oil upon assembly."

#9

Posted 26 May 2016 - 09:00 AM

Yes, 20/50 and Graphogen seemed to be a safe first-rotation mix, but not good enough when the tolerance was too tight.

DSC01132.JPG 48.34K

21 downloads

DSC01132.JPG 48.34K

21 downloads

The MiniSpares blurb on the site is misleading regarding the bushes, and made worse by my not reading it correctly - DAM8889 is not in fact the floating type, but it's not clear whether the floating alternative C-AEA3240 is or is not suitable for A+ engines.

Be interesting to see whether they bother to re-write the accompanying texts for those two parts.

The shells looks worse after 1.500km than the previous lot did after 50.000km .................

DSC01134.JPG 48.94K

17 downloads

DSC01134.JPG 48.94K

17 downloads

DSC01136.JPG 53.71K

8 downloads

DSC01136.JPG 53.71K

8 downloads

#10

Posted 26 May 2016 - 12:13 PM

This is the MS gibberish for the DAM8889 : my comments in bold :

running clearance for this gear-front bush running clearance finished size 1.503" +0.002"-0-0" (which implies an ID of 1.503" to 1.505" ? but the FRONT bush zone on the crank is 1.625" !!)

for race 1 thou more clearance with plus 1 thou tolerance obut never undersize. (implies what ? 1.503" to 1.507" ?)

front bush 1.628" +0.002" -0.0" never undersize as it requires clearance. (this is better, a front-bush size, 1.628 to 1.630 ; presumably because 1.625 plus 3 to 5 thou gives 1.628 to 1.630 ?)

For race allow an extra thou 1.504" +0.001" only. (implies ID upper limit of 1.505" ? two lines above it's 1.507 ? - again these are REAR sizes)

if cranks are worn measure crank and allow 3-5 thou running clearance (on which one - front or back, or both ?) and race use 5-7 thou on front bush and 4-5 thou on rear bush

ANYWAY

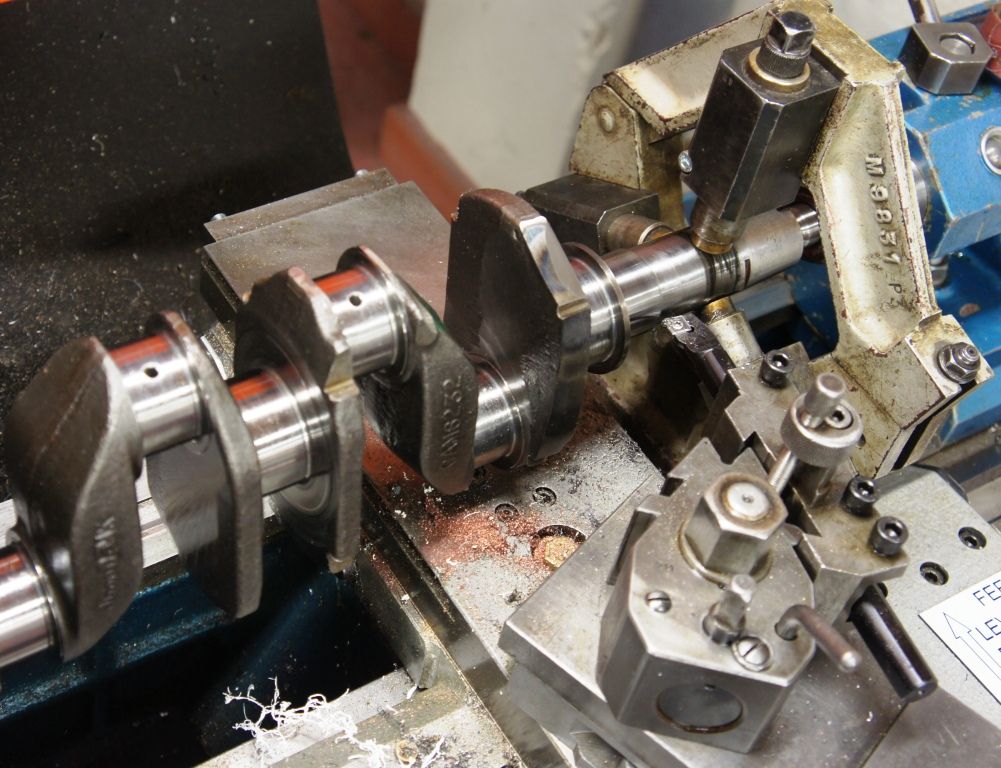

I have grasped the nettle and following the advice from my local machine shop I have done the work on my own lathe .......... sorry about the boring bar, it was the only tipped tool I could get into the right approach.

The crank has cleaned up at 41.13 - 41.14 mm, 1.619" - 1.620", so the only question is whether a DAM8889 can be used.

Attached Files

Edited by MontpellierVanMan, 02 June 2016 - 07:56 PM.

#11

Posted 26 May 2016 - 02:19 PM

It's all chinese to me.

I don't have permission to view your pics !

Who polished your crank ? looks amazing

Pete

#12

Posted 26 May 2016 - 02:30 PM

You have to sign in to see the pics, or maybe they weren't fully loaded when you tried ?

The finish is 240 emery-cloth, followed by 500 grit, if I was any good on the lathe I wouldn't need them.

#13

Posted 27 May 2016 - 08:51 AM

Only just now picking back up on this thread.

The crank has cleaned up at 41.13 - 41.14 mm, 1.619" - 1.620", so the only question is whether a DAM8889 can be used.

Yes, they are typically 0.020" under sized.

I wouldn't use a floating bush (even if they were suitable for A+), they are much too hard (they have to be due to the nature of them) and if you think this bush made a mess of your crank, the floating bushes would do far worse.

#14

Posted 27 May 2016 - 09:04 AM

Just found this for info. Might be something interesting in it etc.

http://mini-racing.f...ment-des-bagues

#15

Posted 27 May 2016 - 11:03 AM

I'm inclined to agree with you, Moke, about the floating idea - whilst it's nice to think of sharing the wear across two surfaces I can't help feeling that the original system worked fine (with the right materials) and I don't want my primary gear bore getting shagged by a potentially inappropriate bronze running in it.

Edited by MontpellierVanMan, 27 May 2016 - 11:10 AM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users