Some photos

The bush still in situ

Bush removed (turned out)

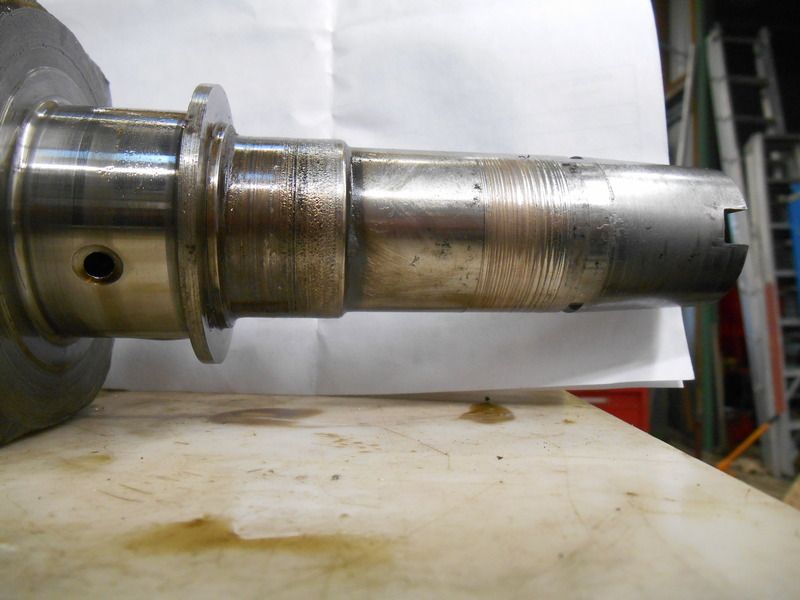

and this is what it did to the crank It now has to be ground and likely custom bushes fitted);

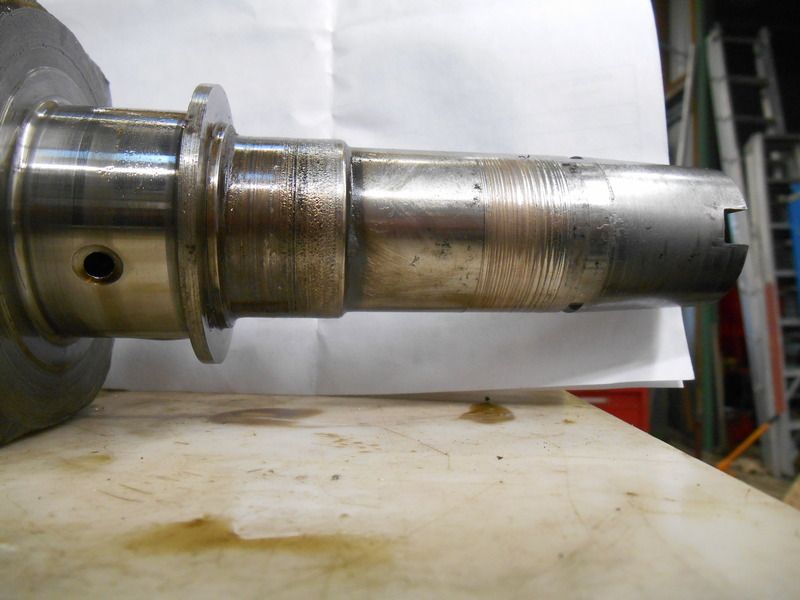

This is a NEW bush, note the extrusion markings;-

Just my thoughts and some investigation work so far.

The material is WAY too hard, and while it can be used in some situations for a bushing material, it is commonly used for fasteners in a marine environment as an alternative to stainless. It also has a fairly high rate of thermal expansion (ie, on the sizes and temps we are dealing with, it can grow 0.004 to 0.005").

It appears that while these materials are around a similar cost, or maybe a little cheaper then the DEVA material, being considerably harder allows the bushes to be pressed in at room temperature, this is not possible with the DEVA material as it will simply crumble away to powder. The correct factory advise relating to the original DEVA bushes is to chill them in Dry Ice, this shrinks them (according to factory info) by 0.003 to 0.005" for fitting. Curiously, I've never found this info an any UK publication, but it was in our Aust Factory Manuals.

According to DEVA, the finish is best done as a machining operation (ie, lathe or reamer), where as while the Silicon bronze bushes can be turned, they would benefit from honing, which for a non-ferous material, is a highly specialised process (and not one most automotive machine shops could do correctly).

The Bronze material sooner or later will, not maybe, but will pick up on the shaft of the crank, as the bronze is so hard to start with, and this is the beginnings of the failure process seen in this thread, though on another I saw, it also ruined the primary gear. The DEVA material, being basically compressed powder cannot pick up.

As I mentioned before, the Bronze is basically a sealed material (hence why it's so favoured in a marine environment) and cannot accept oil. Grease would appear to be a better lubricant here, however, the speeds involved will cook the grease in short time. If Oil is used, as soon as it runs off, there is no lubrication (and then the bush picks up on the shaft and it's game over). The Bronze to the touch always feels dry.

The very early Minis had a White Metal Bush Primary Gear, however, they also had an Oil Feed to them, which lead to a slipping clutch. The factory spent some considerable time and funds finding a dry running alternative - DEVA.

The DEVA material is already pre-loaded with Graphite and will accept Oil. This material to the touch always seems to have a slipriness about it.

OK, Mr. Primary Gear Bush maker(s), can we now get proper bushes again for our Primary Gears?

Disclaimer: No, I don't have any association with DEVA.

WP_20160517_07_40_21_Pro.jpg 50.65K

117 downloads

WP_20160517_07_40_21_Pro.jpg 50.65K

117 downloads WP_20160517_07_39_40_Pro.jpg 26.6K

98 downloads

WP_20160517_07_39_40_Pro.jpg 26.6K

98 downloads WP_20160517_07_40_01_Pro.jpg 32.39K

105 downloads

WP_20160517_07_40_01_Pro.jpg 32.39K

105 downloads