Hi Guys,

I got the tips made using C101. They worked a treat! With the first couple of welds the tips initially stuck to the work after welding, but could be prised off easily. There also get hotter than my normal tips, and you can see that there is some bluing evident - this may be down to the small diameter I was using.

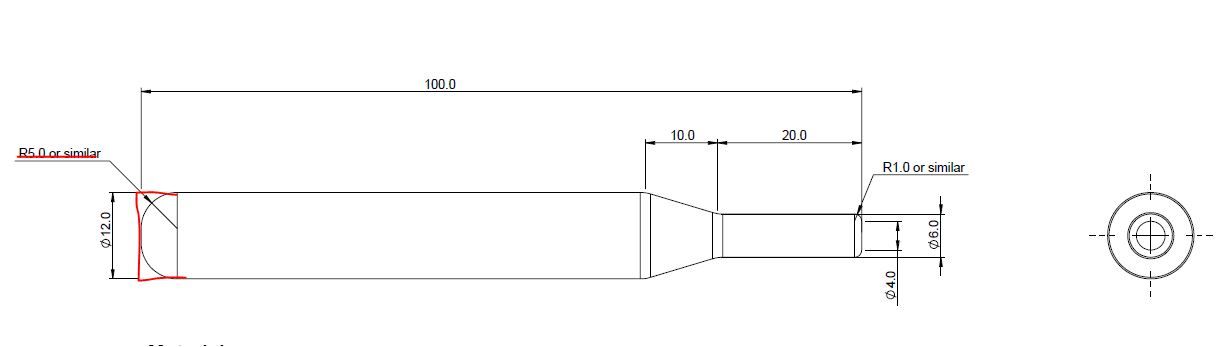

given it was £2.50 for the material and £20 to have them turned up I don't think I can complain ![]()

Hope this helps,

Chris