Tool list to get you started , information nicked from here and there if you want a credit just pm me and ill stick it in.

If you have any suggestions yourself, or anything I've missed please add them to this thread.

You do not need all these tools it's just a guide for building up over the years.

ideal Christmas prezzys or birthdays presents .

the best place for help is http://www.theminifo...sked-questions/

Not doing spanners, trolley jacks, screwdrivers or axle stands or any safety stuff just get the best stuff you can at the time.

Tools faq

To start depends on the year of your mini if it pre 1990 then it should be imperial if it after 1990 then it should be metric but 99% of minis are still inperial.

but then it may depend on if people have changed nuts and bolt and if rover ever changed the size from imperial to metric.

Tips

See if you can get a trade card from Halfords or beg one, they do not tell you the discount that will be knocked off you have to go to the till and ask as it's per tool.

But for most Halfords tools they knock good money off and keep the recite forever if you want the life time warranty.

Why Halfords well there the most common place to get stuff for me and they isn't to bad at all.

Failing that go ask the family what they have you might be surprised what's tucked away??.

Safety glasses ( Yer I know ) under the car, grinding, messing with brake fluid you only get on set of eyes ( i told you so )

Knee pads or a good peace of foam to kneel or sit on, in 30 year's time you will wished you had listened.

Gloves there cheep these days use them.

Your best friend is wd40 or similar, if it is in the car or on the engine generally it dose not need spraying, if its outside the car and you think it needs spraying start spraying a week before removing and

twice a day if possible as it takes time to get penetrate deep into the rust.

If you need a one off tool like reamers for the suspension, engine lift's ect ask at the local club, Give them a deposit as a act of good faith and check it ok before you leave them and ask how it works,

clean it, do not abuse it and return it asap in the state you received it or better and if you break or lose it buy them a new one or come to some deal. People who have these tools know they wear out and break at times just tell them if it goes wrong.

Look on ebay for tools and you will find that certain expensive company's have the same looking tools with different name's on them, these are mass made and mainly are in the 99p bracket but a lot higher price.

Quality off tools = Money

Snap-on - top end loads of money only worth while if you in the trade or loaded.

Halfords, brit tool, look on ebay price's are all over the place but most have warranty's but good for a good 20 years or so. Also go down the parts shop and have a good look round.

Market stall and the 99p shop, Total crap to best tool's ever. you never can tell but if you ever need to grind a spanner, hit with big hammer or use a screw driver as a chisel these are the one's to use.

Respect

Respect the tool clean and polish them, select the right tool for the job, when there worn out throw them away or in the 99p draw.

When you don't show respect they will bite and hurt you ask 99% of people on here.

General tools

Decent set of imperial (that's inch, not metric) spanners/sockets

A second 1/2" and 7/16" spanner

1/4 drive imperial socket set

Torque Wrench

Posidriv & Philips screwdrivers

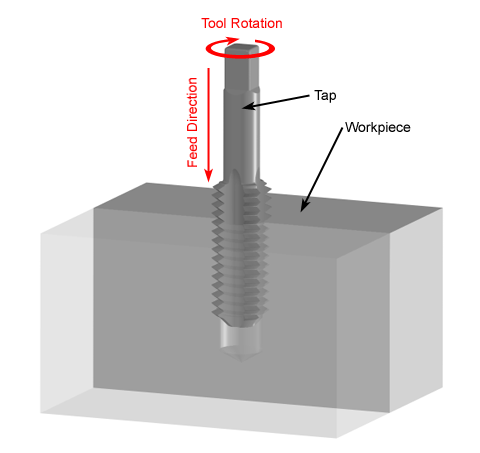

Tap & die set (imperial)

A magnetic tray to save you losing all those nuts and bolts

Coffee/sweet/jam jar of choice for storing nuts and bolts

A BIG hammer, or BFH, for those "rhubarb" moments

Rivet gun and rivets for those arches

Pliers

Mole grips

Wire brush(electric and hand)

Crowbar

Long needle nose pliers

Rubber mallet

Circlip Pliers

Roll Pin Punch

Center Punch

Brass Drift

Easy out

Hacksaw (junior and senior)

Brakes Specific

5/16" Brake adjusting spanner

Brake Pipe Spanner (7/16th's)

Eezebleed brake bleeding kit

One of those things for fitting circlips on rear brake cylinders

Engine Specific

Spark plug socket

Timing gun

Compression tester

Points File (anyone remember/got these)

Valve spring compressor

Piston ring compressor

6 & 7mm sockets and long extensions for jubilee clips.

Oil filter wrench

Feeler gauges

Dwell meter (multimeter may or may not include dwell)

Impact driver for door striker plates and such.

Flywheel locking tool (aka an old main bearing shell)

Flywheel puller and old drive shaft (use the drive shaft to "ring" off the flywheel, just smack it with a hammer)

Suspension Specific

1 5/16" Impact socket for Hub centre nut, disc braked minis. Also fits steering wheel retaining nut

1 1/2" deep socket for Swivel pin cups, all minis

Grease gun

BIG breaker bar for disc hub nuts

Cone compressor tool

Hub puller

Scissor type ball joint splitter

Electrical Specific

Multimeter

test lamp

Quality electrical crimping tool

Assorted crimps

Quality wire cutters

Wire strippers if you feel the need

Other Usefuls

Copper Grease (not technically a tool but, required)

Sand Paper/ Wet & Dry Paper

Masking tape

Labelling kit (so you remember where it all goes) post its, masking tape, bags, cardboard with holes

Blowtorch

Bottle of rust converter

A LARGE can of penetration oil (wd40 is ok, but plus gas kicks ass)

A roll of Gaffer Tape

Oil drain tray (an oil can with side cut out just doesn't cut it!)

A magnet on a bendy rod for retrieving dropped bolts

A third hand for all those jobs where two isn't enough

A nice cup of tea and a sit down

Torch (with a magnetic holder if possible)

***********************************************************************************************

***********************************************************************************************

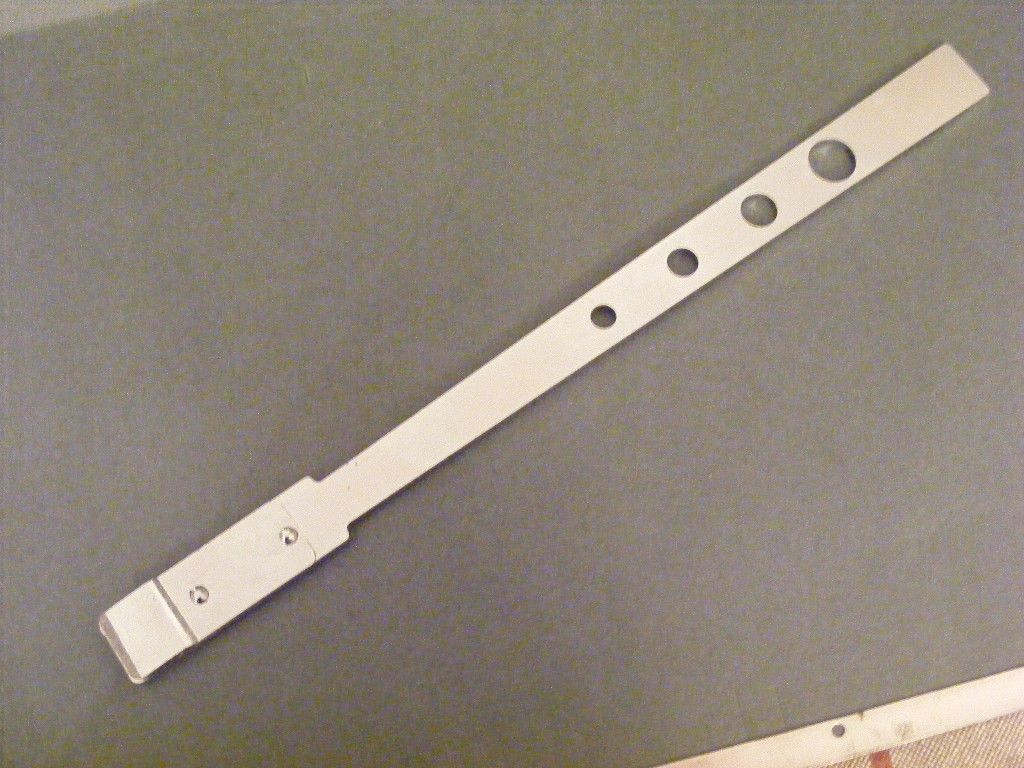

SPECIAL WASHER FOR SEATING CV AND WHEELBEARINGS S/STEEL

***********************************************************************************************

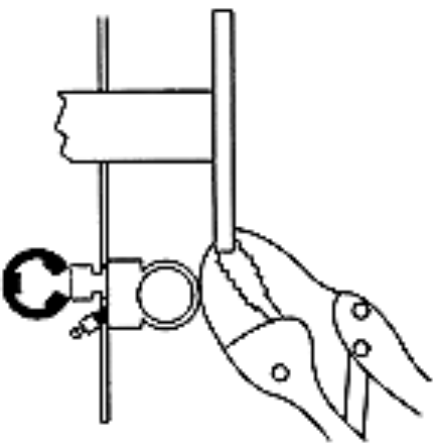

CV BOOT CLAMPS

CV GREASE EAR PLIERS x1 GARAGE - for fitting cv boots that fail every few years

**********************************************************************************************

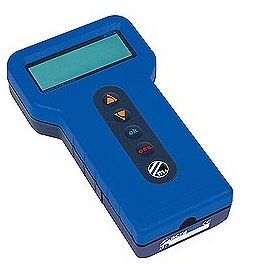

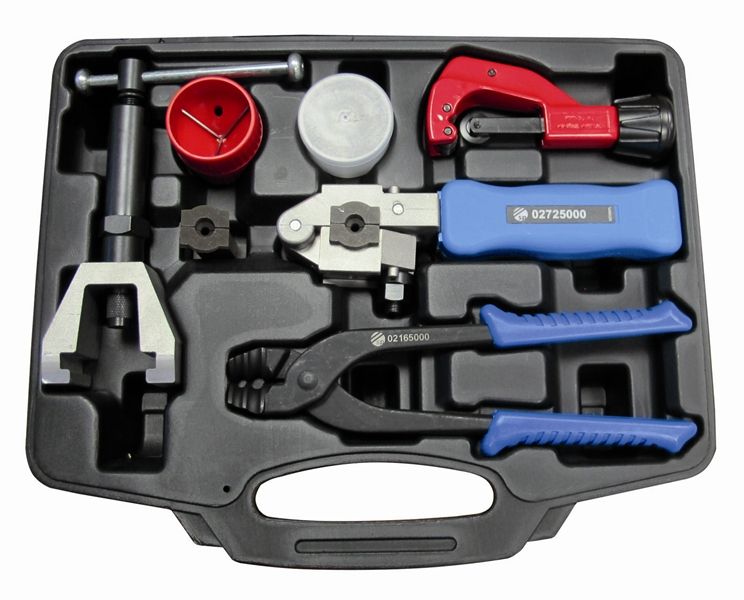

Sykes pickavant Acr4

Acr4 + you need a cable

4 line display for mpi/spi only

****************************************************************************************************

CLASSIC MINI BRAKE AND CLUTCH CLEVIS PIN FITTING TOOL

****************************************************************************************************

Flaring tool

for brake pipes and clutch pipes

Flaremaster2 - The Original Hand Held Automotive Brake Pipe Flaring Tool

Features:

Quick-release chuck for positive engagement of the punch

Fast-turn coarse thread on hydraulic ram, for quick assembly

Locking bolt with swivel pin, for fast tightening

Inter-changeable dies, held in place by magnets

Enhanced bridge unit for greater strength

Ergonomic handle moulding, for greater comfort

Unique, original, patented design for producing high quality pipe flares - on the vehicle

Flaring pipes on the vehicle allows for accurate repair sections to be spliced following repair work or accident damage

Creates SAE & DIN single and double flares

Supplied in moulded plastic box

Contents:

- 02725600 - Flaremaster2

- 02165000 - Dual Size Brake Pipe Aid Plier

- 02210000 - Telescopic Pipe Tube Cutter: 3-32mm

- 02730000 - Pipe Deburring Tool: 3.2-16mm

Flaremaster2 - Spare Parts

02724470 - Flaremaster2 - Flaring Die Block Set - 6mm

02725170 - Flaremaster2 - 4.75mm, 3/16 OP1 Punch SAE

02726170 - Flaremaster2 - 4.75mm, 3/16 OP1 Punch DIN

02727170 - Flaremaster2 - 4.75mm, 3/16 6mm OP2

02726500 - Flaremaster2 - Set of Punches: 4.75mm, 3/16

02720470 - Flaremaster2 - Flaring Die Block Set: 4.75mm, 3/16

02725270 - Flaremaster2 - Replacement Clamp Assembly

02725500 - Flaremaster2 - Replacement Handle Assembly

02726070 - Flaremaster2 - Hydraulic Ram Assembly

02725570 - Flaremaster2 - 6mm OP1 Punch SAE

02726270 - Flaremaster2 - 6mm OP1 Punch DIN

Specifications

Weight - 2.8

Dim 1 - 300

Dim 2 - 350

Dim 3 - 100

Spare Parts - 02725000,02160000,02210000,02730000

**************************************************************************************************

Flywheel locking tool, very handy - somerford minis

Bolts in the starter hole and stop the engine turning over .

**************************************************************************************************

Oil seal tool / clutch tools

minispares - Ace tool for installing clutch oil seal.

if you don't use one off these make sure you tape up the spines on the crank/gear to stop damage

to the seal as the spines cut into the seal and cause another leak costing you pulling the engine out again and a

new clutch also sets it to the correct depth and so easy to use.

Primary Gear puller - for pulling the gear off and the seal with it.

( this is a maxi engine puller as a mini one is longer )

to install or remove one of these

********************************************************************************************************

Flywheel puller

Make sure you take the washer out by the bolt.

They can be a right sod get off and with a bang to, heat and big bar.

*********************************************************************************************************

Gear rod punch

For punching out the pin at the end of the selection rod.

Mini mine

*******************************************************************************************************************

Synchrony Hub Ball & Spring Fitting Tool

Guesswork's

has available a Classic mini Synchro Hub Ball & Spring Fitting Tool. This tool is designed to aid the installation of the balls and springs within

the synchronisation gear hubs as fitted to any Mini or Metro with synchromesh gear engagement, or transverse equivalent, such as Midget, Marina, Ital, Moggy Minor.

Including 848, 970, 997, 998, 1071, 1098 & 1275 engines

Very simple and easy to use, if you have built a gearbox with one of these tools you will never want to go back to the old method

Instruction video available online

****************************************************************************************************************************

Slump plug

5/8 unc helicoil kit / read up about this before you do anything

******************************************************************************************************

crimping tool

Propa crimping tool

*******************************************************************************************************

12v tester

Probly the most important tool in your mini tool box ![]()

***************************************************************************************

Multimeter

*************************************************************************************************************

Jump leads

don't leave home with out them

**************************************************************************************

Engine rebuild tools

Micrometers 0 - 1" , 1-2", 2-3"

Vernier calipers 0 - 150 mm

Depth micrometer 0 - 1"

Dial Gauge and stand 0 - 0.5" or 1"

Feeler blades 0.001 - 0.035"

If you can afford it a dial bore guage 0.5 - 1" and 2-3"

Telescopic guages

Small hole guages (not overly needed but nice if you have them)

Cam timing protractor

Taps for thread cleaning, 1/4" UNF/UNC, 5/16" UNF/UNC, 3/8" UNF/UNC

Torque Wrenches 5-20 lbft, 20 - 100 lbft, 50 - 250 lbft.

A centre lathe (or a friend who can do machining for you)

A vertical milling machine (or a friend who can do the machining for you)

Slip guages (definatly a luxury item, perfect for rocker geometry setting)

Plastiguage 0.001 - 0.003"

24in breaker bar at least 1/2" drive!

Length old scaffold tube (aluminium kind is best 4 ft in length)

4 ft growler bar.

Flywheel puller

Plumbers blow lamp (the kind that has a propane bottle separate to the torch)

Some means of brazing.

80 and 120 grit wet and dry paper for lapping.

320 and 1000 for polishing items

Bench grinder

Valve grinder (machine shop)

Valve seat cutters/grinders (machine shop)

A dremel or at least a drill.

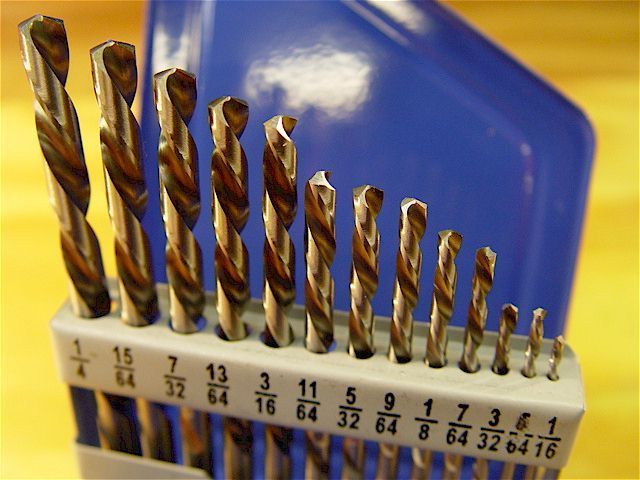

Drill set

Straight edge 24 in (this is a luxury)

Burette 50cc

Helicoil inserts (Decent machine shop will have these)

A selection of needle files

Hand file medium cut 12 in

Bastard file 18in .

Gasket scraper (decent one)

Some means of checking camshafts (this could be your engine that you are building, or better still that old 998 engine you had in the corner of the garage stinking up the place!!)

Degreasing agents

Engine stand

Some of these tools need practice to be able to use accurately/safely so a freindly engineer is the best contact here. Others may need the services of you local machine shop, but remember it is up to you to check any machined dimensions to be sure that they are correct before you build the engine.

************************************************************************************************

Brake tools

buy the tool in advance

or to free two hands try this, The Shifty Way!

REAR BRAKE ADJUSTER TOOL

Easy bleed

Bleeding brakes on your own

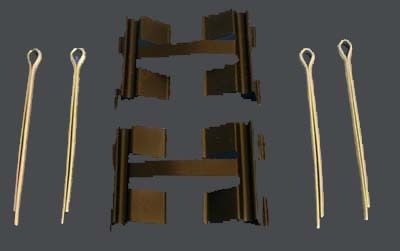

If your fitting front pads get a new set of these as well.

For squeezing the spring on rear brake

********************************************************************************************************************

Taps

taps you need a correct drill size, hats small than the tap .

Hard as ******* when they break - you can not re drill them needs to be taken to a machine shop.

5/8 16 uns - crank shaft

5/8 18 unf - Head Temperature hole 37/64" drill bit

5/8 unc - sump plug

Austin Crankshaft 5/8" x 16 Whitworth Special Tap (Whit Form)

The nose (damper) and flywheel (tail) end of Classic Mini and all transverse Austin, Morris, British Leyland, America, 1100, 1300 and Rover crankshafts, and the nose pulley end of all inline crankshafts such as Marina, Ital, Midget, sprite, moggy minor and many more.

Including 803, 848, 948, 970, 997, 998, 1071, 1098 & 1275 engines

This tap is not a Whitworth Fine which technically does not exist.

The thread in the crankshaft is not 5/8 inch unf, unef, uns, Whit Fine or WF, as these are all incorrect in one way or another.

This thread size, type and pitch was also used on the by-pass hose pipe 12A2075 that screws into the head on earlier models.

*********************************************************************************************************************************************

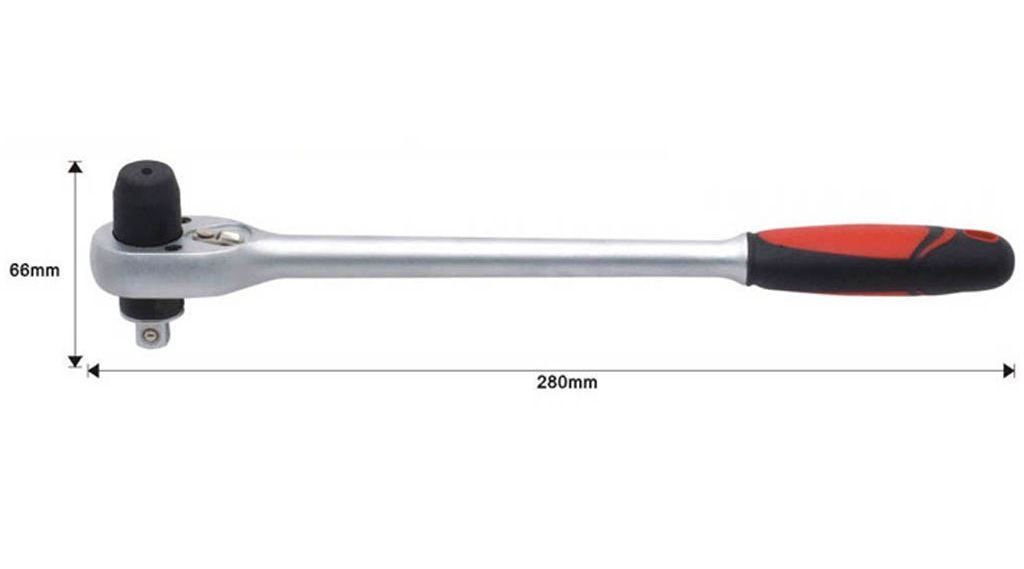

Wrench and power bars

These come in a few sizes and in this country they are imperial and the basic one's are 1/4" 3/8" 1/2" and big boy's toys 3/4".

Now spend some money as cheep one's break and slip and that results in money and blood.

1/4" drive are great for tight spaces and upto about 11mm max.

3/8" drive are i guess the all rounder from 8mm to about 17mm.

1/2" drive are for the bigger nut's 17mm to power bar size.

Power bar, breaker bar this is maily for undoing nuts that a rachet may slip when used p.s. they do break.

*******************************************************************************************************

Sockets

Sockets there are few kinds 6 point and 12 point deep and shallow and standard metric imperial.

Me i try to stick to 6 point as there a little better chance of not rounding the nut off but if your going to use apr nuts then you 12 point sockets.

Deep socket great peace of kit as they keep your knuckels away from the car and a god send for exhaust clamps,

the down side is you have to keep them stright and square to the face of the car part.

Standard sockets better as they sit close to the face of the car part, now id get decent set for every day use and a cheep set that you can hammer on to rustey bolts.

Socket sizes

1"1/2 Deep= Ball joints / Gearbox internal / Flywheel

15/16" or 24mm = Sump plug

1"1/8 = Gearbox internal / Drum Brake Hub Nut / Crank Pulley Bolt

1"3/16 = Verto nut

1"5/16 = Hub nut / Tower Bolts / S-Wheel Boss /Fits crank pulley bolt / camshaft nut / post-76 front Subframe tower bolt

11/16" = wheel nut's

1" = oil re leaf nut

**********************************************************************************************************************************************************

Wind screen tool

DONT NOT USE FAIRY LIQUID AS IT GOT SALT IN IT AND ROT'S THE RUBBER.

**********************************************************************************************************************************************************

Cone tool

Two types imperial and metric after 1976

Metric thread is the coarse one, but the imperial one will fit and go in and then strip while your finger are around ???

********************************************************************************************************************************************************

Ball joint splitter

Note any damage to the rubber's is a mot fail from the 4/2012

**************************************************************************************************************************************************

Read me!!!!!!!!!!!!!!

Tool Envy Syndrome (TES)

Tool Envy Syndrome (TES) is a serious condition that afflicts, in varying degrees, nearly all men who are interested in mechanical things. It is very important to recognize and deal with this condition before it becomes serious; left untreated it can lead to a far more serious condition: Inflammation of the Credit Card (ICC). TES is known to strike under the following circumstances:

Browsing the latest tool catalogs or sale flyers

Visiting stores such as Grizzly or Harbor Freight (Warning: while much less so than in earlier years, the tool department at Sears can still trigger small attacks)

Visiting the shop of a friend who has more and/or better tools than you have

Surfing the web site of someone with a well-equipped shop

Seeing a well-equipped shop in magazines such as Home Shop Machinist

Tool Envy Syndrome tends to strike young men particularly hard, due its close relationship to a similar condition: Gear Acquisition Syndrome (GAS). Over time, in most men, both of these conditions tend to lessen in severity. In fact, it can be shown that gradual accumulation of tools and gear over a period of years can control both conditions while minimizing the risk of Inflammation of the the Credit Card (this is known as the Mature Phase). It has also been widely observed that getting married and having children can moderate the risk; primarily, it is believed, due to counseling from a loving wife and the sobering effect of having lots more bills to pay.

Tool Envy Syndrome cannot be controlled by any known drugs (although its effects can be exaggerated by the use of alcohol). Therefore, treatment is currently limited primarily to counseling methods. The first step is admitting that you have a problem. Here are some additonal pointers:

Avoid situations that are likely to cause an attack

When visiting tool stores, leave your credit card at home (Warning: in severely afflicted individuals this can trigger emotional breakdown, fits of crying and other irrational behavior)

Meditate on the fine collection of tools that you already have; recognize that time will make it better

Find a quiet place. Visualize your ideal shop. Repeat to yourself "It is coming"

I hope you have found this information to be helpful. As a TES/GAS sufferer myself (now in the Mature Phase) I felt compelled to pass it on to you.

DRILL PRESS: A tall upright machine useful for suddenly snatching flat metal bar stock out of your hands so that it smacks you in the chest and flings your beer across the room, denting the freshly-painted part which you had carefully set in the corner where nothing could get to it.

WIRE WHEEL: Cleans paint off bolts and then throws them somewhere under the workbench with the speed of light. Also removes fingerprints and hard-earned calluses from fingers in about the time it takes you to say, ''What the...??''

ELECTRIC HAND DRILL: Normally used for spinning pop rivets in their holes until you die of old age.

SKILL SAW: A portable cutting tool used to make studs too short.

PLIERS: Used to round off bolt heads. Sometimes used in the creation of blood-blisters.

BELT SANDER: An electric sanding tool commonly used to convert minor touch-up jobs into major refinishing jobs.

HACKSAW: One of a family of cutting tools built on the Ouija board principle. It transforms human energy into a crooked, unpredictable motion, and the more you attempt to influence its course, the more dismal your future becomes.

VISE-GRIPS: Generally used after pliers to completely round off bolt heads. If nothing else is available, they can also be used to transfer intense welding heat to the palm of your hand.

WELDING GLOVES: Heavy duty leather gloves used to prolong the conduction of intense welding heat to the palm of your hand.

OXYACETYLENE TORCH: Used almost entirely for lighting various flammable objects in your shop on fire. Also handy for igniting the grease inside the wheel hub you want the bearing race out of.

TABLE SAW: A large stationary power tool commonly used to launch wood projectiles for testing wall integrity.

HYDRAULIC FLOOR JACK: Used for lowering an automobile to the ground after you have installed your new brake shoes, trapping the jack handle firmly under the bumper.

EIGHT-FOOT LONG YELLOW PINE 2X4: Used for levering an automobile upward off of a trapped hydraulic jack handle.

E-Z OUT BOLT AND STUD EXTRACTOR: A tool ten times harder than any known drill bit that snaps neatly off in bolt holes thereby ending any possible future use.

BAND SAW: A large stationary power saw primarily used by most shops to cut good aluminium sheet into smaller pieces that more easily fit into the trash can after you cut on the inside of the line instead of the outside edge.

TWO-TON ENGINE HOIST: A tool for testing the maximum tensile strength of everything you forgot to disconnect.

CRAFTSMAN 1/2 x 24-INCH SCREWDRIVER: A very large pry bar that inexplicably has an accurately machined screwdriver tip on the end opposite the handle.

AVIATION METAL SNIPS: See hacksaw.

PHILLIPS SCREWDRIVER: Normally used to stab the vacuum seals under lids and for opening old-style paper-and-tin oil cans and splashing oil on your shirt; but can also be used, as the name implies, to strip out Phillips screw heads.

STRAIGHT SCREWDRIVER: A tool for opening paint cans. Sometimes used to convert common slotted screws into non-removable screws.

PRY BAR: A tool used to crumple the metal surrounding that clip or bracket you needed to remove in order to replace a 50 cent part.

HOSE CUTTER: A tool used to make hoses too short.

HAMMER: Originally employed as a weapon of war, the hammer nowadays is used as a kind of divining rod to locate the most expensive parts adjacent the object we are trying to hit.

MECHANIC'S KNIFE: Used to open and slice through the contents of cardboard cartons delivered to your front door; works particularly well on contents such as seats, vinyl records, liquids in plastic bottles, collector magazines, refund checks, and rubber or plastic parts. Especially useful for slicing work clothes, but only while wearing them.

DAMMIT TOOL: Any handy tool that you grab and throw across the garage while yelling ''DAMMIT'' at the top of your lungs. It is also, most often, the next tool that you will need.

Part 2 below

Edited by ukcooper, 13 March 2016 - 07:00 PM.