After reading Clive trickeys book he says it was the pre 63 850 minis that could take up to 6500 and post 63 could take up to 7500rpm which mines a 1979 850 I believe one of the last years the 850 was produced. If to fit a fast road cam do you need the block machining out. And what cam would anyone recommend if we were to stick to building a fast road 850cc. That driveable.

Tuning The 850 Engine, Formula 850

#16

Posted 16 December 2015 - 10:39 PM

#17

Posted 16 December 2015 - 11:02 PM

The words 'fast road' and '850 Mini' don't really go together ![]() . It would simply be 'not quite so slow'.

. It would simply be 'not quite so slow'.

These days, due to unavailability of 850 performance parts, it is not worth spending a lot on an 850 apart from building a reliable engine with a few more bhp.

The Kent 256 cam should be OK for road use, or an MG Metro cam (almost the same as the Kent 266 which is another alternative.

You will need to gas-flow the head and maybe fit slightly larger inlet valves, increase the CR and source some good pistons.

You could try an HS4 carburettor and lighten the flywheel a bit.

42 to 45 bhp is attainable with reliability, but do have the block line-bored to take camshaft bushes.

#18

Posted 17 December 2015 - 11:00 AM

850 +060 Schmidt pistons with 2cc dish, flush deck height.

Thick flange block with cam bearings, modified main caps, center strapped, pocketed for 36x29 940 head.

OAP 275/400 cam.

Modified 515 crank.

Modified 998 rods.

Teflon buttons.

2 x either 1 1/8 or 1 1/4 SUs.

Steel flywheel and backplate.

4 syncro box, starting with 3.7 cwp but ratio will be finalised after dynoing.

Mate wants something fun to drive on his 10 mile country lane commute.

Edited by OzOAP, 17 December 2015 - 07:23 PM.

#19

Posted 18 December 2015 - 10:34 AM

i know with the crank I used was nothing special may have been 850 steel crank

or just tufrided as raced mni7 on a budget

think we used modified s rods and I know we used flat top powermax pistons + 60 I think

but this is a long time ago 40 years and now old and forgetful

#20

Posted 20 December 2015 - 05:35 PM

515 crank

Properly modified 998 rods

OAP 265/360 cam

295 head

Showed 90hp on KAD dyno but reduced boost and ignition to give 75hp as it was on std 3 syncro box.

Edited by OzOAP, 20 December 2015 - 07:25 PM.

#21

Posted 31 December 2015 - 11:08 AM

Did BMC not make a "race" crank from EN40B for the 850?

#22

Posted 31 December 2015 - 11:48 AM

Did BMC not make a "race" crank from EN40B for the 850?

No.

#23

Posted 07 January 2016 - 09:24 AM

are you sure? Moke spider

#24

Posted 07 January 2016 - 09:53 AM

are you sure? Moke spider

If they did, it wasn't generally offered to the masses.

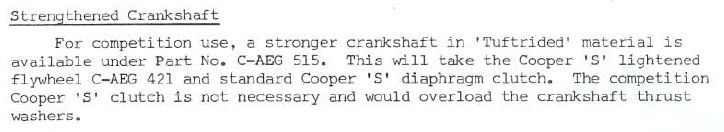

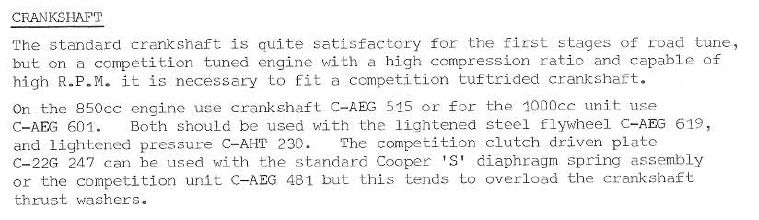

<Edit: From BMC's early ST Book;-

From Leylands ST Book (which was about the last published for the 850)

They refer, in both of these, as the crankshaft being Tuftrided.

Nitriding and Tuftring processes are used on particular grades of steels, ie, you wouldn't have much success trying to Tuftride EN40B and likewise, you wouldn't do much good trying to Nitride EN16T, which the 850 cranks were made from. >

Edited by Moke Spider, 07 January 2016 - 10:11 AM.

#25

Posted 07 January 2016 - 10:32 AM

They did make an EN40 crank for the 850, I have one in my shed, it is stamped AEG516

#26

Posted 07 January 2016 - 11:33 AM

They did make an EN40 crank for the 850, I have one in my shed, it is stamped AEG516

If thats the stamping no. then the part no. is AEG515. Sorry but it's EN16T.

<Edit: If it's EN40B it will also be stamped EN40B. Rare crank all the same. >

Edited by Moke Spider, 07 January 2016 - 11:39 AM.

#27

Posted 07 January 2016 - 11:45 AM

The two materials are also visually different, EN40B usually has a darker shade, when EN16T will be lighter-brighter colour

I've also heard words of special 850 crankshafts, but never seen one in flesh so cant comment on that.

#28

Posted 07 January 2016 - 01:49 PM

You're probably right Spider (you usually are!). To be honest I'd not paid much attention to it, I bought it with a load of EN40 'S' cranks and just kind of assumed it was also EN40 because of the AEG part number. Either way it's another interesting thing to have!

#29

Posted 07 January 2016 - 03:07 PM

Boy is ever a long time since I have been on here. Mini Se7en's yep used to work the spanners on a championship winner or sort of . I worked for Terry Pudwell who cam second & third in the championship in 76 & 77. So this is what I remember of his engine. Crank was STD but tufrided. Engine overbored +60 and you need to pocked the bore for the valves around 6 mm you may also have to deck the block to match up to the pistons which from memory had pockets in as well. The need to be powermax. Cam was 649 and get a duplex timing chain on it. The rods lightened were polished so you could see your face in them. The flywheel will need lightening and balancing as well. We used a modified Cooper S dizzy on it. Think that is about it. The engine used to be built by a guy called Brian Laurence who passed on years ago but it got a few lap records. The push rods were lightened & polished and the cam followers lightened and drilled to let the oil out. Rocker gear was Cooper S lightened and off set to give 1.5 lift. Second year we used Norton push rods which were alloy. After practice I used to take the rocker box cover off and set the tappets hot. The pit guys wondered what I was up to at first but it seen gout out we had some trick rockers. Would not advise you using them as they do not last that long. Hope some of this helps. RR

Forgot to mention the carb was a 45 DCOE webber with one choke blanked off on a long manifold exhaust the obligatory LCB coming out of a side exhaust, (No silencers back then) straight cut drop gear to a straight cut box.

Edited by Road Runner, 07 January 2016 - 04:03 PM.

#30

Posted 07 January 2016 - 06:41 PM

Roadrunner - Interesting Car - would have been a real screamer, would have loved to have seen that one on the track.

You're probably right Spider (you usually are!). To be honest I'd not paid much attention to it, I bought it with a load of EN40 'S' cranks and just kind of assumed it was also EN40 because of the AEG part number. Either way it's another interesting thing to have!

Ah, the devil is always in the detail and that bit about being usually right,,,, Hmmmmm,,,,, don't worry mate, I stuff things up as good as the next guy ![]()

<Edit: Tip - rarely (and I'm scratching my head to think of an example) are the Stamping Nos. or the Casting Nos. the same as the Part No. and 9 999 times out or 10 000 they will be different Nos. eg;-

A C-AEG648 cam will be stamped 649

Ever tried looking through a Factory Listing for a 12G940 Cylinder Head - doubt you'll find one!

There are a few exceptions though - I just can't think of any right now!

Also, most (all?) ST Parts - by Part No. - are prefixed C-xxxx (have a look at the snippets I posted up ^) . The AEG Prefix was used on many 'ordinary' parts too, most notably on the pre-A+ 1275 Engines. >

Edited by Moke Spider, 07 January 2016 - 07:51 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users