I've got great access to the door striker plate, as the screws were seized I can get some liquid wrench and heat in here no problem

Posted 02 November 2015 - 04:52 AM

Posted 03 June 2016 - 02:33 AM

Well after a 6 month hiatus, where other work and projects got in the way, I'm back on the mini.

I started back on removing the entire cant rails from the roof, cleaning up the back side with a knotted wire brush in my grinder until shiny and then hitting it with some weld thru (zinc) primer.

In an effort to future-proof, I also welded on some captive nuts and flat washers to the back of the B posts for seatbelts while they are off too.

Then I'd like to get the inner A post panels off .....

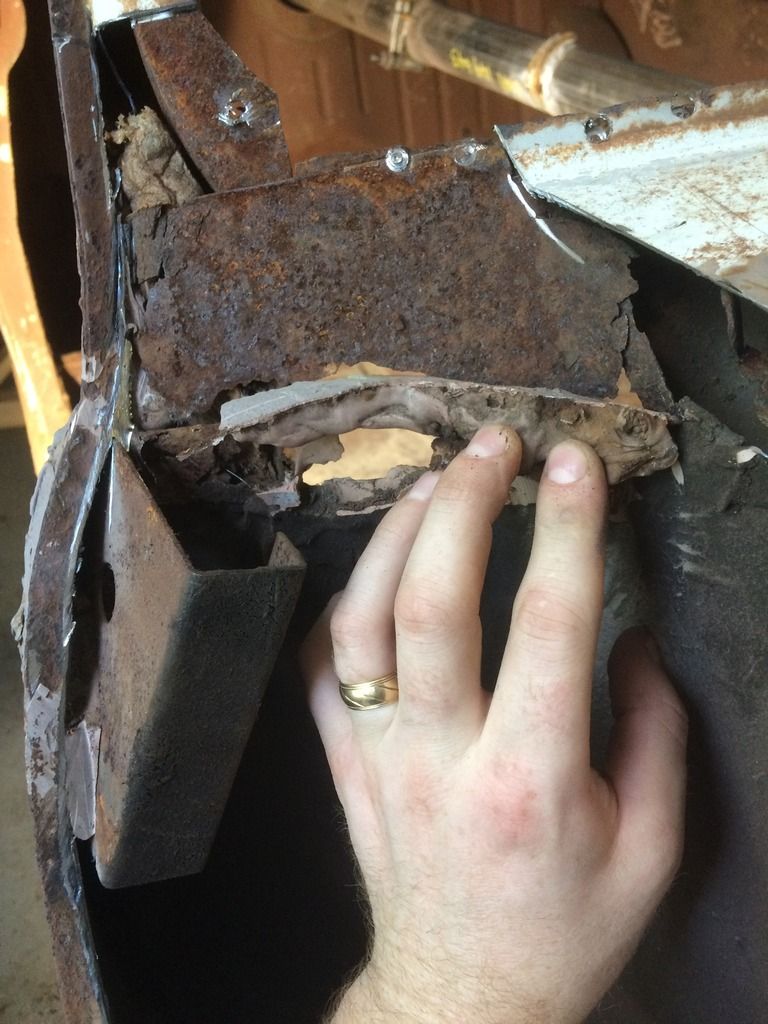

.....because of this furry mess inside. This is looking inside the A post from the opening at the top now available since the cant rail was removed.

But before that I have to take off the upper dash rail, which is attached to the bulkhead, but to get the rail off I have to get the scuttle panel off first.

et voila!

rustiness is served, delicious!

closing panel made of galv sheet and body filler.

Also the upper door hinge bracket is some piece of metal girder from sometime in the 70's most probably.

Had the remove the severed bit off the old wing first to get to the scuttle ends.

This was the other side

What is this foam stuff in the A pillar? Why is it there and what was it meant to do, apart from trap moisture and make rust?

Is it asbestos? Either way It's getting removed post haste.....

Then i could remove the scuttle

Rusty underside, but its just surface corrosion and should coem off, I plan to renovate this inner part combined with M machine end repairs.

Oh and then I started on removing the the dash rail, and there are twice as many spot welds. I think they built it by spot welding the dash rail to the bulkhead and then spot welded the scuttle to both the bulkhead and the dash rail.

And the spot welds are very hard to find, and no order to them, probably totally up the chap on the assembly line where he chose to put them I guess?

It looks a mess, but I can tidy both flanges up when they are separated

Oh and here are some bonus pictures of the lovely body filler job to the A panel.

Here's the inside without any cant rails attached.

I'm now thinking of starting to brace the shell since I'm taking more of the inner panels out.

Edited by Chappers, 03 June 2016 - 02:35 AM.

Posted 03 June 2016 - 07:32 AM

Posted 03 June 2016 - 10:50 PM

Posted 04 June 2016 - 07:03 AM

Exciting looking project you have there, nice to see a really early shell with it's subtle differences getting sorted out. What I think I would do rather than a bike engine is go A series (1380cc) with a supercharger good power and torque and totally in keeping with the period. As after market supercharger kits where offered early on in the Minis production. Keep the updates coming and I too am envious of your garage.

Posted 04 June 2016 - 03:10 PM

Posted 04 June 2016 - 05:01 PM

When you put it that way it makes perfect sense to use what engine you can find. Good luck with the build.

Posted 05 June 2016 - 01:05 AM

Posted 05 June 2016 - 01:10 AM

Posted 05 June 2016 - 06:03 AM

Posted 17 June 2016 - 12:53 AM

Edited by Chappers, 17 June 2016 - 12:54 AM.

Posted 18 June 2016 - 03:29 AM

Posted 24 June 2016 - 01:45 AM

Posted 26 June 2016 - 07:00 PM

Nice Project, definitely would like to share notes. I'm in Georgia by the way.

I feel the same about resurrecting such a unique find, especially when you really think about the history.

This thread will be a welcomed source of motivation.

0 members, 1 guests, 0 anonymous users