Ethal, regarding the coil springs and how they are wound, yes, your thinking is sound and right, however, in the case of springs for these cars, there's no room for little more than one and a half turns, some have about two, so there's just not enough turns in there to get some with higher pitching.

Going to a smaller wire size would help in this regards, however then the overall rate will be way too soft.

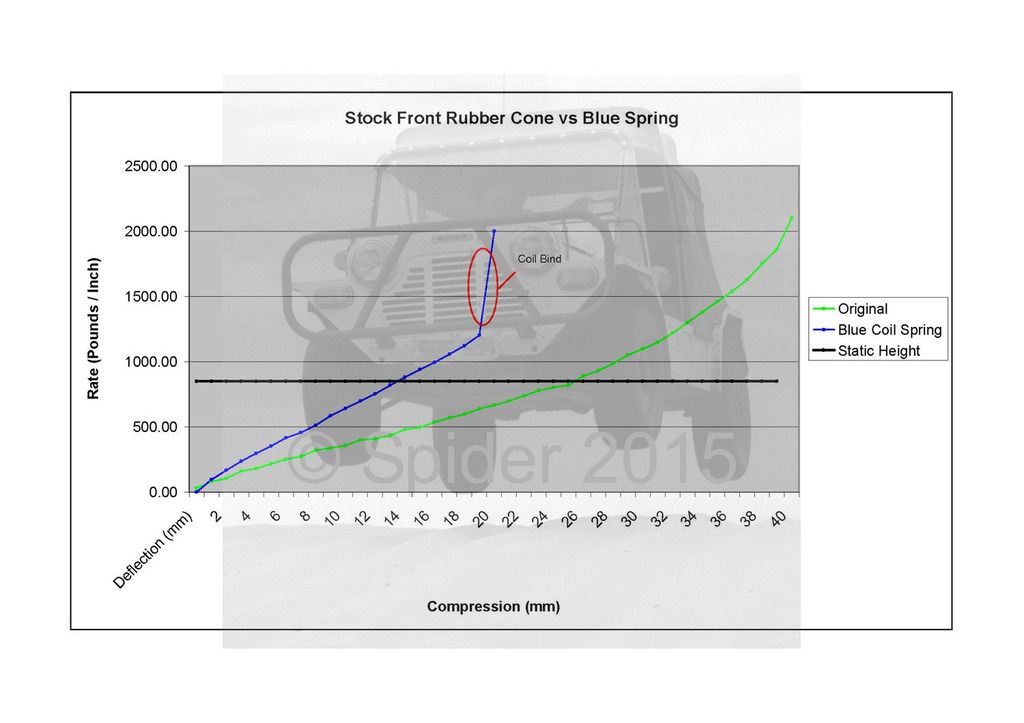

I spent around 3 months, every day, working with a Spring Engineer in their R & D Dept (Better Springs), with all the bells, whistles, tables (as it was then) and tricks in the book to get a conventional spring to work and take the place of the Donut, at the end of the period, the Engineer asked me one morning "Ever thought of using rubber?" (Mind you, we had many cones laying about - it was just that given the overall picture, he could clearly see and drew the same conclusion as Dr. Moulton did in the day).

I forgot to ask. Was this just the rubber donut or with a standard trumpet?

I'll double check later, but I'm pretty sure that figures are using the stock front trumpet.

Edited by Moke Spider, 28 September 2015 - 04:57 AM.