Mk2 Cooper

#106

Posted 31 December 2015 - 01:21 PM

#107

Posted 31 December 2015 - 02:38 PM

So true. Where did you purchase the long arms from?

#108

Posted 31 December 2015 - 02:46 PM

#109

Posted 01 January 2016 - 08:42 PM

Added the support bracket

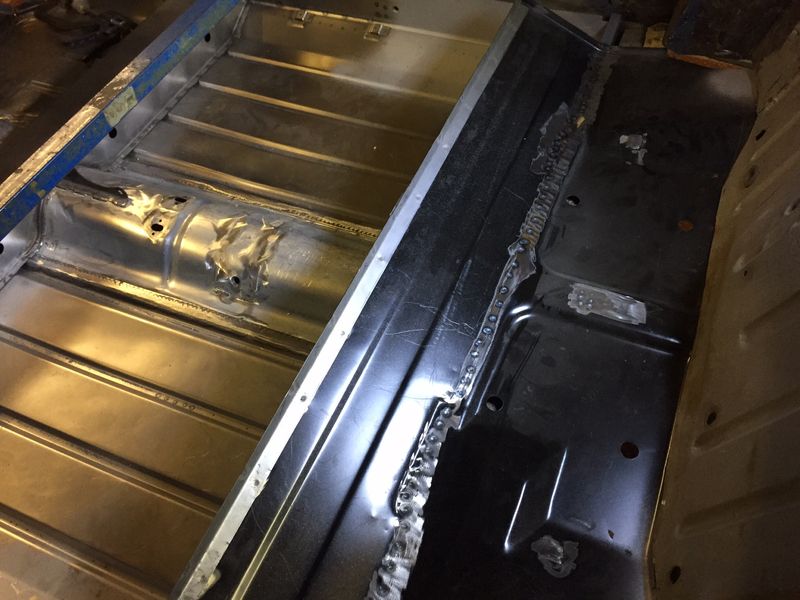

Couple of pics of rot and poor repairs on old floor

Then dropped in new boot floor and checked alignment

Just need to weld it in position and decide which parts to cut out next

#110

Posted 01 January 2016 - 11:22 PM

#111

Posted 02 January 2016 - 05:14 PM

Managed to double check squareness and spot weld boot to heel board so at least shouldn't move, also made a reinforcing angle for edge of seat base so getting there slowly

Need to stop and think now as unsure what to tackle next as unsure how stable will be if I take off a rear quarter

#112

Posted 02 January 2016 - 11:39 PM

#113

Posted 09 January 2016 - 05:21 PM

Also bought my a panels while placing order

So cut out the old bulk head

Then transferred boot board brackets to new one and trial fitted

Must say so far have been well impressed with m machine,

I just need to get boot floor down a little on drivers side to get everything level and get it welded in position but ran out of time so it's a job for next week, hopefully now have a month or so work before need any more panels. Was just unsure on order of fitment but hopefully got everything right in my head now so can crack on with it.

Edited by Daz1968, 09 January 2016 - 06:23 PM.

#114

Posted 10 January 2016 - 08:02 PM

Just Seen those a panels all compete look loads easier to fit? Would it be possible to pm with some more pics of those?

Thanks

#115

Posted 10 January 2016 - 08:38 PM

#116

Posted 11 January 2016 - 06:30 AM

Thanks, I have found m machine stuff brilliant and these a panels will be much better as the car had pattern ones on already and not sure of post condition, they are a little more expensive but worth it. Will sort a few pics when I go down garage

Thanks daz,

I have to the say the same in the past when I have bought from m-machine they have been loads better than most places. Cheers if you could that would be great dont mind paying more for a better panel :)

#117

Posted 16 January 2016 - 05:25 PM

#118

Posted 16 January 2016 - 08:29 PM

#119

Posted 16 January 2016 - 10:47 PM

Cracking on now Daz ![]()

The old rear bulkhead didn't look too shabby, why did you need to re-new it mate?

#120

Posted 16 January 2016 - 11:11 PM

Edited by Daz1968, 16 January 2016 - 11:11 PM.

4 user(s) are reading this topic

0 members, 4 guests, 0 anonymous users