Mk2 Cooper

#91

Posted 29 November 2015 - 12:11 PM

I already have rear subframe in position and measurements are correct, hopefully will ensure new floor goes in correctly, will check all measurements again before welding

#92

Posted 29 November 2015 - 06:55 PM

#93

Posted 01 December 2015 - 05:24 PM

Finally got the drivers side door step welded in

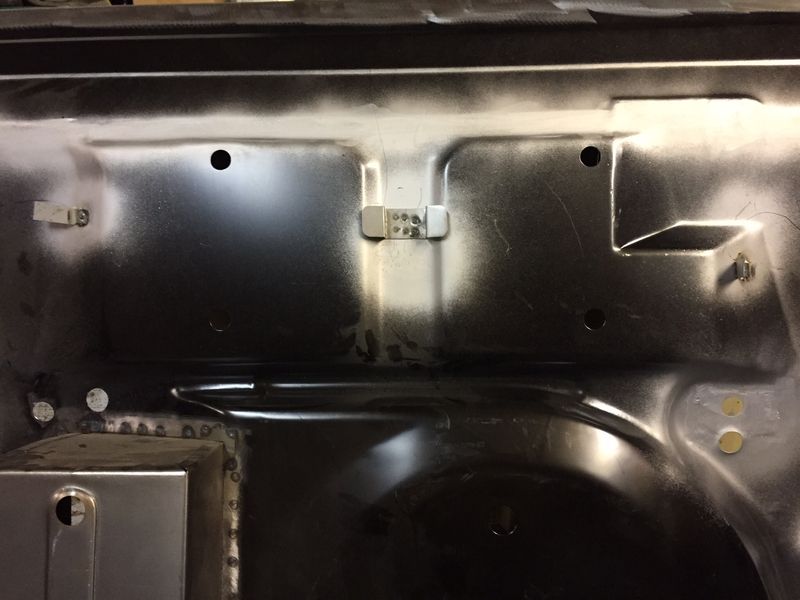

Then spent a little time making the clips for the boot floor and welded in position along with the battery earth bolt and put in extra hole for the rh tank breather

Been contemplating next stage but have discovered the drivers rear quarter is worse than I thought as had a repair previous and it's distorted so think far easier just to replace it, also the rear panel and rear seat back are beyond economical repair so got to get a few more parts than I originally planned, but don't want to leave anything that may bite me in the future.

Edited by Daz1968, 01 December 2015 - 05:25 PM.

#94

Posted 01 December 2015 - 09:40 PM

#95

Posted 02 December 2015 - 09:56 PM

#96

Posted 02 December 2015 - 10:04 PM

#97

Posted 19 December 2015 - 01:02 PM

I went with magnum quarters as the only part that appears poor fit is the front edge and that will be being cut off anyway. I compared them to some heritage ones at the mini centre and for the saving in cost will be fine, I used magnum doorskins on my mk1 and had no trouble with those so will probably use again.

Just need to find some spare time now

#98

Posted 19 December 2015 - 01:51 PM

Glad to here your all well again. Looks like it was xmas for your cooper there already... Looking forward to seeing your progress after xmas then :)

#99

Posted 28 December 2015 - 03:17 PM

Cut out old back panel then clamped new one in position

Will have some more time later in week to trial fit window and bootlid before welding in position,

Then once I know this is correct will drop out the boot floor as in theory that should rest on heel board and rear panel and should then be in correct position, although will be measuring again before welding

Hope everyone had a good xmas.

I also had a panel beating kit for xmas so hopefully will be able to use it soon. The rear panel does have a strange lump near the petrol cap hole so will address that after fitting, presume the tools are worn a little at heritage.

Must say though I can't see point in buying the boot hinge repair panel when this panel is only about £25 more and at least will have no panel joints in the boot area.

#100

Posted 30 December 2015 - 05:32 PM

First removed it and cleaned and weldable primer added where required

Then trimmed to size on pillars and clamped in position

Then welded and ground down

Plug welded boot catch

Spot welded to the shelf

Then just trial fitted a bootlid to see how it looked.

I have to pluck up the courage to drop out the boot floor next hopefully have a go the weekend

#101

Posted 30 December 2015 - 06:48 PM

Looks good. Great job ![]()

#102

Posted 30 December 2015 - 08:37 PM

Nice

#103

Posted 30 December 2015 - 11:45 PM

#104

Posted 31 December 2015 - 08:10 AM

Love this project, looking really good, keep up the updates

#105

Posted 31 December 2015 - 12:59 PM

Great work Daz. I'm following now.

Whats the duty cycle like on your spot welder? I'm guessing 3 welds per minute??

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users