Mk2 Cooper

#196

Posted 07 March 2016 - 09:11 PM

#197

Posted 08 March 2016 - 06:30 AM

Thanks, no the inner a panel is not fitted yet but I am going to spot weld them to inner wing before I fit it, was just trial fitting for now, the outer a panels are very good and using door to align them has worked out quite easy.

Ok wicked yeah can see that must have made the door alinment so much easier defo will be the way i go with mine when i start it :)

#198

Posted 09 March 2016 - 07:17 PM

top job mate!

#199

Posted 12 March 2016 - 10:27 PM

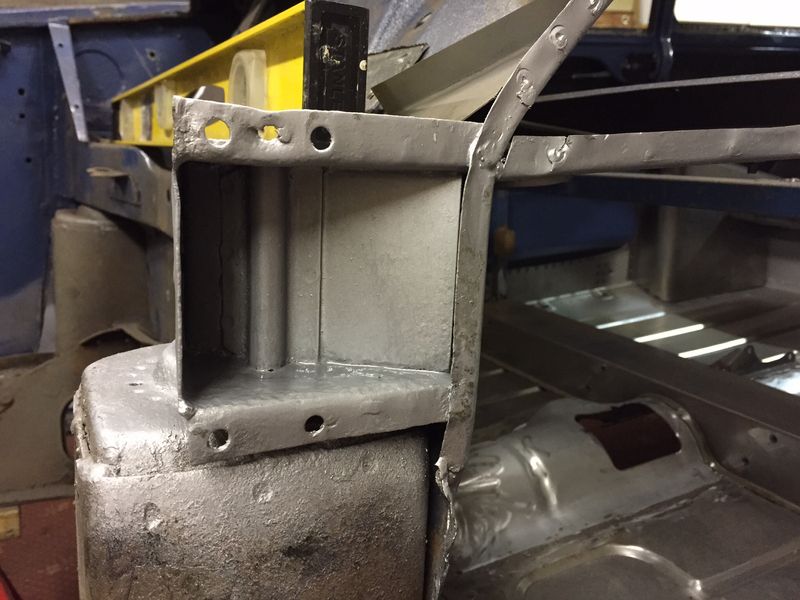

Cleaned up ends of cross member

Fitted new bracket but only after careful measurements

Then fitted new homemade reinforcing plate

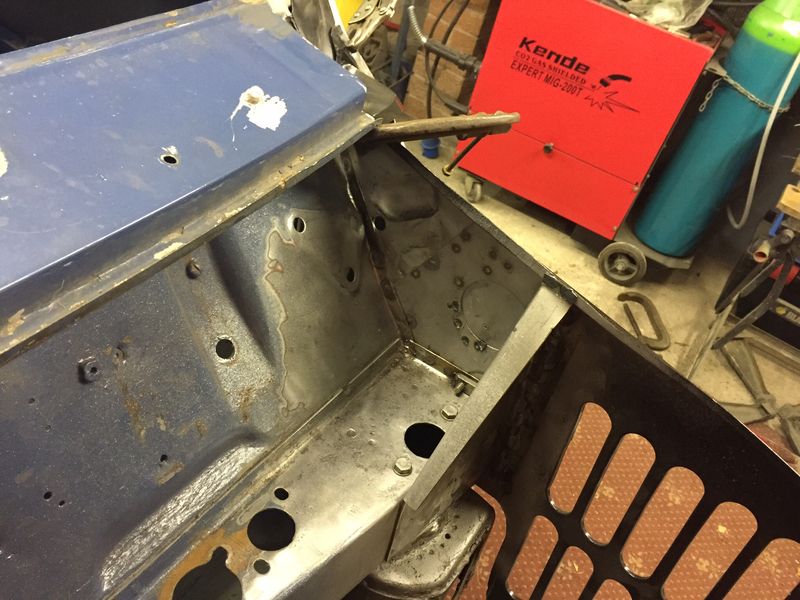

Had to make a few adjustments to the m machine end piece as it was slightly different to the original and prevented me getting inner wing in correct place

Then I removed inner a panel closer and repaired a small section at end of the shelf

Then trial fitted the inner wing, drilled holes for plug welds etc

Then the one step back happened, the inner wing fits perfect apart from top near a panel, need to remove it and add a piece in the back so I can spot weld it to the outer a panel, after a lot of worrying it appears others have had same or similar issues with heritage passenger side inner wing so at least I am not alone with the problem

As can be seen fit in all other areas is fine, I even trial fitted the bonnet and it all looks ok.

Was hoping to get this fitted today but at least is now know what to do to get it right, according to comments from others I shouldn't have same issue on other side but only time will tell,

Forums are great sources of information though and these problems are just there to test us,

#200

Posted 12 March 2016 - 10:41 PM

It was a bit of two steps forward and one back today

Cleaned up ends of cross member

Quality job this. I'm interested to know how you got the rust / carbon out of that front subframe. It can be a real pain even using chemicals / wire brushes / shot blasting

#201

Posted 12 March 2016 - 10:47 PM

It wasn't to bad rust wise though just a bit of surface rust, on flatter external areas I also use strip and clean discs on an angle grinder, not cheap though at about £7 per disc but only had to buy 2 so far.

#202

Posted 12 March 2016 - 11:07 PM

Thanks... I also use the fibre wheels :)

#203

Posted 13 March 2016 - 07:37 PM

#204

Posted 14 March 2016 - 12:00 AM

#205

Posted 14 March 2016 - 11:42 AM

#206

Posted 19 March 2016 - 06:10 PM

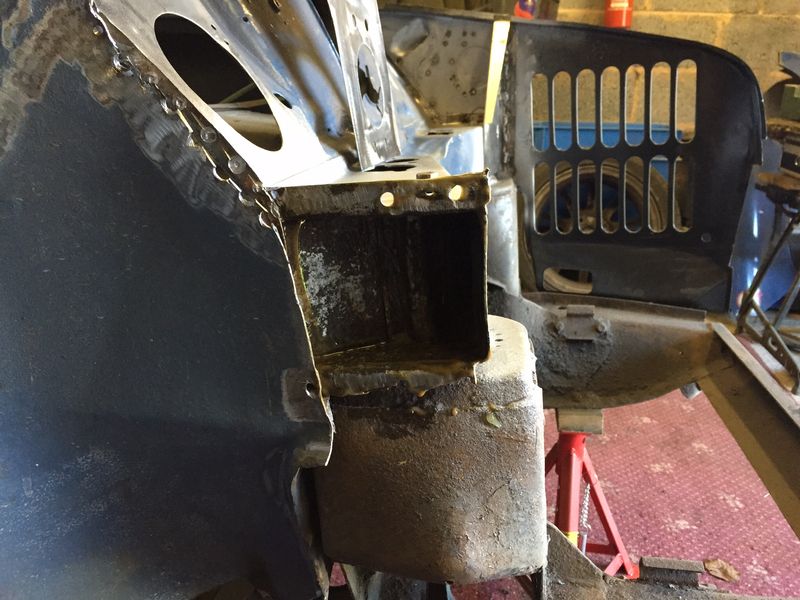

Made a template for new shape

Welded a piece in to correct shape, however I didn't grind fully flush as it won't be seen and hopefully will help with the strength to the joint, the heritage panels are not very thick and the butt welding I find quite tricky

Trial fitted the inner a panel and made sure was ok, then started welding the inner wing in place, ran out of time but will finish it off next time, needs a bit of dressing and filling in places, mainly where I have fitted the patch in inner wing to correct to early spec

I have checked all measurements I can and am pretty pleased with it so far, once this is fully welded in I can start again on the other side. Then I will run out of panels again. Seems never ending but hopefully only one more panel spend left.

Edited by Daz1968, 19 March 2016 - 06:16 PM.

#207

Posted 21 March 2016 - 09:18 PM

Plug welded to inner wing, and spotwelded the rest including the inner wing return lip to the outer a panel, just need to finish return lip under the floor and fit the closing plate in the inside of a post, then grind down all the plug welds and tidy it up, not sure how to finish the lower sill front lip yet though, need to see some pics of this area on other cars.

I might try spot welding inner a panel to inner wing first though on other side, if I can line it up ok.

#208

Posted 22 March 2016 - 01:13 PM

Coming along nicely :)

#209

Posted 28 March 2016 - 06:00 PM

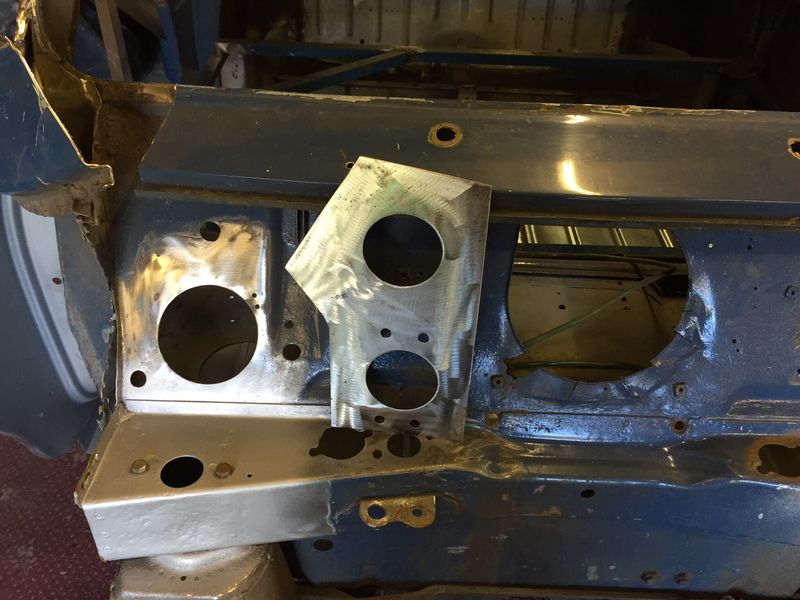

Fitted closing plate on passenger side, needs welds dressing though

Fitted drivers side outer a panel, had a few issues with this one and had to adjust it a little at the top

Then started removing inner wing and cleaned up crossmember end

Also made a new strengener for end of crossmember

Unfortunately I have a sore throat at moment and grinding was irritating it even with a dust mask on so decided to cut hole in rear panel for rh tank and have a general tidy up, hopefully will be better soon.

Hopefully I can finish cutting out panels now and have a good clear out and throw all the old stuff away, trouble is price is low at moment so not many tatters about at moment

#210

Posted 28 March 2016 - 10:59 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users