Mk2 Cooper

#151

Posted 04 February 2016 - 09:59 PM

#152

Posted 05 February 2016 - 02:16 PM

Looking good, really nice neat work. One good thing with something like this is the cost of the parts for the work you are doing will be worth it in the end as the values of earlier minis / Coopers are always on the up. If you forget your time / labour you would see a profit on paper. Keep up the good work.

#153

Posted 05 February 2016 - 05:09 PM

#154

Posted 06 February 2016 - 07:17 PM

#155

Posted 07 February 2016 - 08:54 AM

#156

Posted 07 February 2016 - 04:51 PM

#157

Posted 08 February 2016 - 06:54 AM

Looks good think i may go this route with the mk1 one day :)

#158

Posted 08 February 2016 - 07:44 AM

#159

Posted 08 February 2016 - 08:08 PM

Looking good.

Out of interest why did you seam the panel in behind the B post? No mk1 qtr panels available?

#160

Posted 08 February 2016 - 08:12 PM

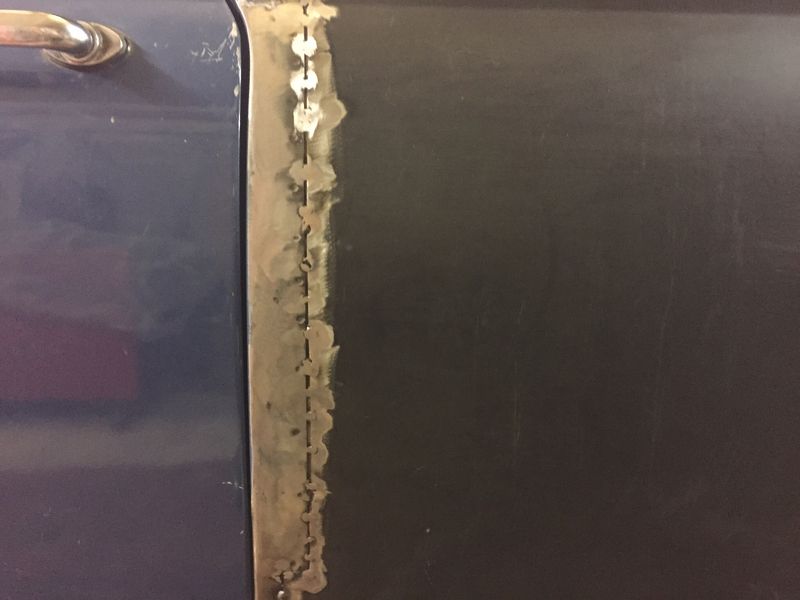

Took longer than I thought but I have the rear quarter spotwelded and tacked in position, I had a few issues with the rail as it had rotted out along top edge, so repaired that first. Fitted ok although needed a few tweeks

Now i would be using Frosts Cold Front when welding that together otherwise you may end up with some distortion/ Looks good though.

#161

Posted 08 February 2016 - 09:20 PM

On the subject of panels, m machine do a mk1 type rear quarter but it doesn't have the upper lip near the waist rail so would still need a long joint, most fit the mk3 quarter cut down and joined as I have. I also didn't want to disturb the profile near the door as it's pretty good.

#162

Posted 08 February 2016 - 10:47 PM

Thanks, may leave seam welding till I have fitted other side, was going to use an airline to cool off but will look into the cold front stuff.

On the subject of panels, m machine do a mk1 type rear quarter but it doesn't have the upper lip near the waist rail so would still need a long joint, most fit the mk3 quarter cut down and joined as I have. I also didn't want to disturb the profile near the door as it's pretty good.

Thought that maybe the case as the door shut/fit does look good.

Keep up the good work

#163

Posted 13 February 2016 - 06:00 PM

Put some more tack welds on the quarter joint, hopefully will keep tacking in between until they all joined

Pic showing distortion, not a lot really and should come out a little further with hammer and dolly

I then moved to other side and cut of remaining quarter and cleaned up waist rail

Welded in the bin and closing panels using new rear quarter to aid alignment

I then spent some time cleaning up all the faces for spot welding the quarter on, so hopefully get it trimmed and fitted next week.

Looks like I will need to order some more panels soon,

#164

Posted 14 February 2016 - 01:13 AM

#165

Posted 14 February 2016 - 10:40 AM

Good luck working out the distortion Daz. Ive found this is difficult to do well as the welded section is much harder than the adjacent panels so its hard to manipulate back into position.

Knowing you you'll get it perfect though ![]()

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users