Ladies and Gents;

I am about to rebuild and refit my Subframe, does anyone have a guide or top tips that I can look at to help.

Help with things like:

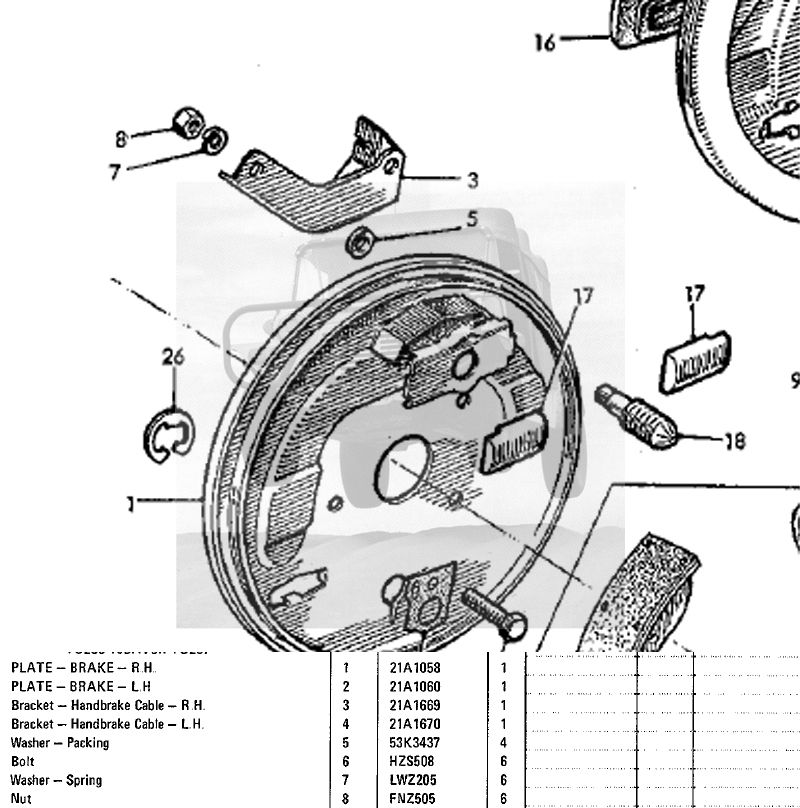

1. How to replace the Handbrake Cable (Handle to Rear Brakes).

2. How much grease, what and where, Hand Brake Cable, Trunnions, Bolts moving parts etc).

3. Fitting and bleeding the brake parts (Cylinders, Pipes etc).

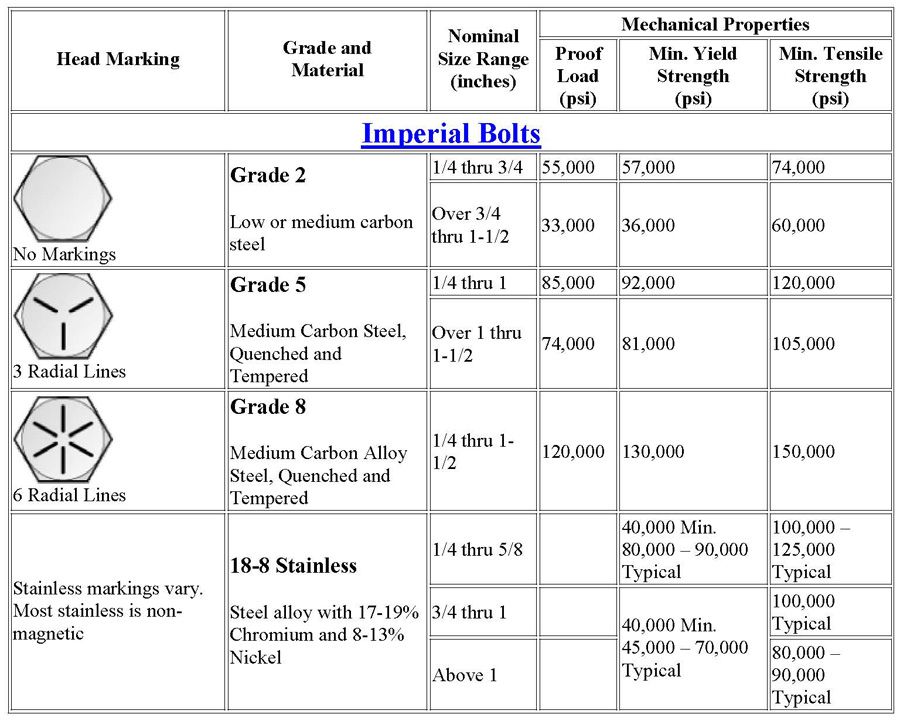

4. What size and grade bolts for the Wheel Arch Subframe mounts.

5. Do I put anything between the Radius Arm and the Backplate (It's separated by 3 washers, one or two of which are doubled up in lieu of a spacer that is no longer available. i.e. do I fill the gap with sealant??

Also which is easier building the Subby on the floor and then fitting it to the car or fitting the bare Subby to the car and then building it?

Any help would be mucho appreciated ![]()

The Car is an Austin HLE 1000, Drum Brakes all around and single brake line from front to rear. Handbrake cable is in two pieces, single line from Handbrake to front of Subby then attaches to another cable that connects to both rear wheels.

Iv'e got Copper Grease in a small tube and Lithium Grease and a hand pull Grease Gun.

Thanks