Martin, sorry but I beg to differ on your theory that Helicals are less efficient and have higher losses.

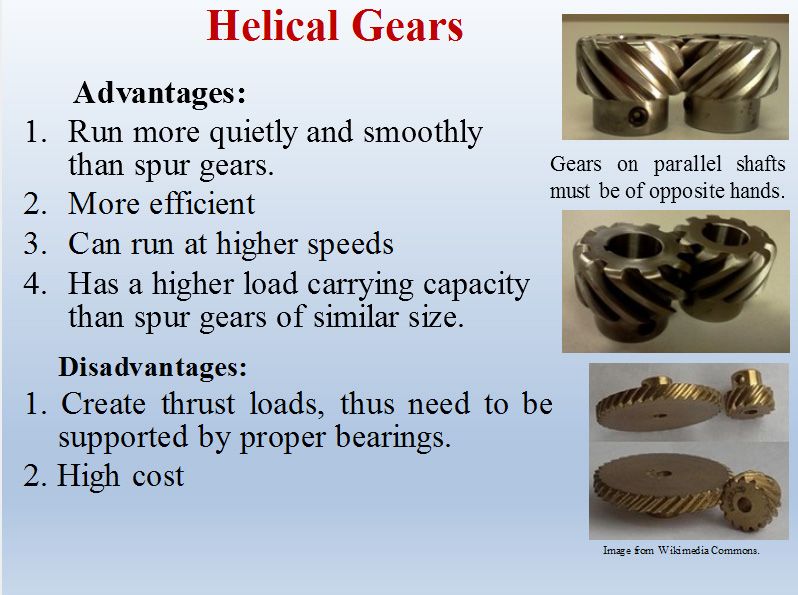

Gear for gear, helicals do have a longer tooth and a high contact ratio, therefore the Spot Pressures of Helical Gears is lower, so the tooth frictional load (wiping effect as you put it earlier) is lower. This is widely known. I may still even have some back to back test data on this. As a further result, Helical Gearboxes run cooler, but not by bucket loads, usually more like by academic numbers.

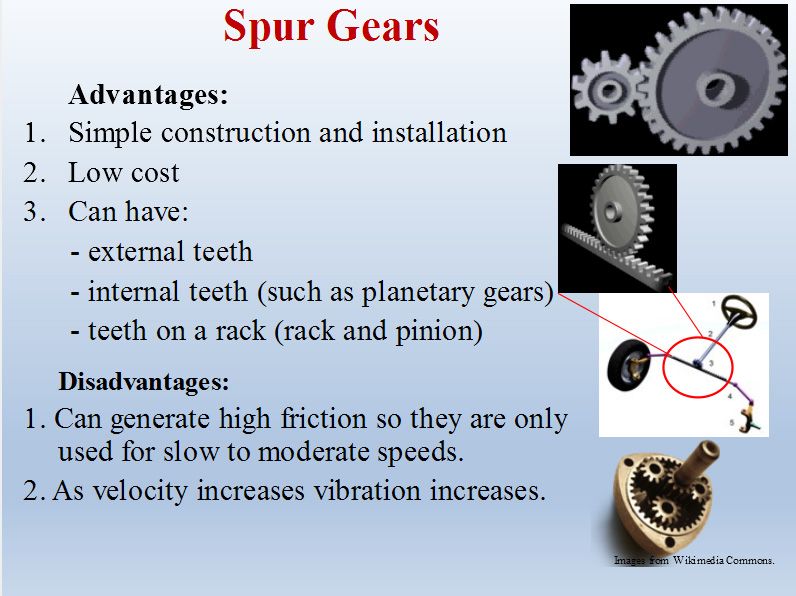

I was able to lay my hands on a couple of slides ('Spur Gears' being Straight Cuts);-

This is also why Helicals are popular in Industrial type gearboxes where noise is not a consideration, but high strength, low losses and a small footprint are a higher consideration.

BUT, I will stress, if the gearbox is not well made or shaftings are out of alignment, Straight Cuts are much more forgiving than Helicals under these less than ideal conditions. I'm guessing here that the 10 - 15% improvement you mentioned may have come from this?

A very close and dear friend of mine (David Rosenthal) did make a Herring Bone set of drop gears a few years back. I have no photos I'm sorry, I'll see if Dave has any. There was an issue he had with them, but it wasn't related to the gears themselves. If I recall, he made these by the double helical method.

Warwick Augustin made a chain drive for the drop gears on one of his race minis. I have no details, but I am aware it did take him a very long time to get it to work right and be issue free. He then ran with it for many years (and may still), so I draw from that he found it was better than gears here.

Edited by Moke Spider, 30 June 2016 - 09:38 AM.