I also welded up any extra holes that aren't needed.

Good thinking, I may do this myself, also, those small square holes held plastic "nuts" on mine so it may be worth welding in some captive nuts instead.

Posted 12 July 2015 - 09:28 PM

I also welded up any extra holes that aren't needed.

Good thinking, I may do this myself, also, those small square holes held plastic "nuts" on mine so it may be worth welding in some captive nuts instead.

Posted 12 July 2015 - 10:14 PM

I also welded up any extra holes that aren't needed.

Good thinking, I may do this myself, also, those small square holes held plastic "nuts" on mine so it may be worth welding in some captive nuts instead.

yeah only ones i kept are for the clocks and the wiper motor couldn't be bothered with any others. I'm still deciding if i want to keep the massive one in the drivers side inner wing as i won't be needing it to put the fresh air pick up through and would mean less intrusion of water into the engine bay

Posted 15 July 2015 - 02:09 PM

Wow, good for you for deciding to do it up.

Posted 16 July 2015 - 02:30 PM

Good for you for keeping her from scrappy. Looks like a lot of work ahead to be done. Are you doing this on your own, and have you set yourself a deadline for completion?? A friend and I are currently doing up a 1972 850 which I last drove in 1995. It has been garaged since, and was buried under 20 years of family clutter!!! Luckily, the main bodywork, apart from the boot area, is pretty sound as I extensively had nearly the entire floor rewelded in 1993.

Came into a bit of money so decided to investigate the condition of the car. This was last August. The car had fallen down on her wheels and looked a sorry sight, after I cleared away the clutter and rubbish from garage. We gave her a good inspection and decided yep to start the process of restoring the car for the road again.

11 months later the car is now been overhauled enough to be able to buy a battery sometime soon to try to start her. It is obviously a satisfying project to be involved in. We are taking it slow with no real deadline as such but it will be good to try to get her through a MOT September time. Regards, Keith.

Posted 16 July 2015 - 09:08 PM

Good for you for keeping her from scrappy. Looks like a lot of work ahead to be done. Are you doing this on your own, and have you set yourself a deadline for completion?? A friend and I are currently doing up a 1972 850 which I last drove in 1995. It has been garaged since, and was buried under 20 years of family clutter!!! Luckily, the main bodywork, apart from the boot area, is pretty sound as I extensively had nearly the entire floor rewelded in 1993.

Came into a bit of money so decided to investigate the condition of the car. This was last August. The car had fallen down on her wheels and looked a sorry sight, after I cleared away the clutter and rubbish from garage. We gave her a good inspection and decided yep to start the process of restoring the car for the road again.

11 months later the car is now been overhauled enough to be able to buy a battery sometime soon to try to start her. It is obviously a satisfying project to be involved in. We are taking it slow with no real deadline as such but it will be good to try to get her through a MOT September time. Regards, Keith.

Posted 18 July 2015 - 10:24 AM

Posted 20 July 2015 - 10:19 PM

Posted 23 July 2015 - 08:03 PM

Posted 25 July 2015 - 05:41 PM

Posted 25 July 2015 - 08:55 PM

Posted 28 July 2015 - 09:21 AM

Posted 30 July 2015 - 08:27 AM

Great stuff,if i was you i would consider doing the boot floor as you are doing both arches the floor is normally really thin around the arches and those repair panels are poo.

I second that I done one of them repair panels in mine and have regretted it ever since they are so poor. If you can buy the full panel and fit as one.

I'll third that. I lined up the repair panel and decided it would be less effort to just replace the whole thing.

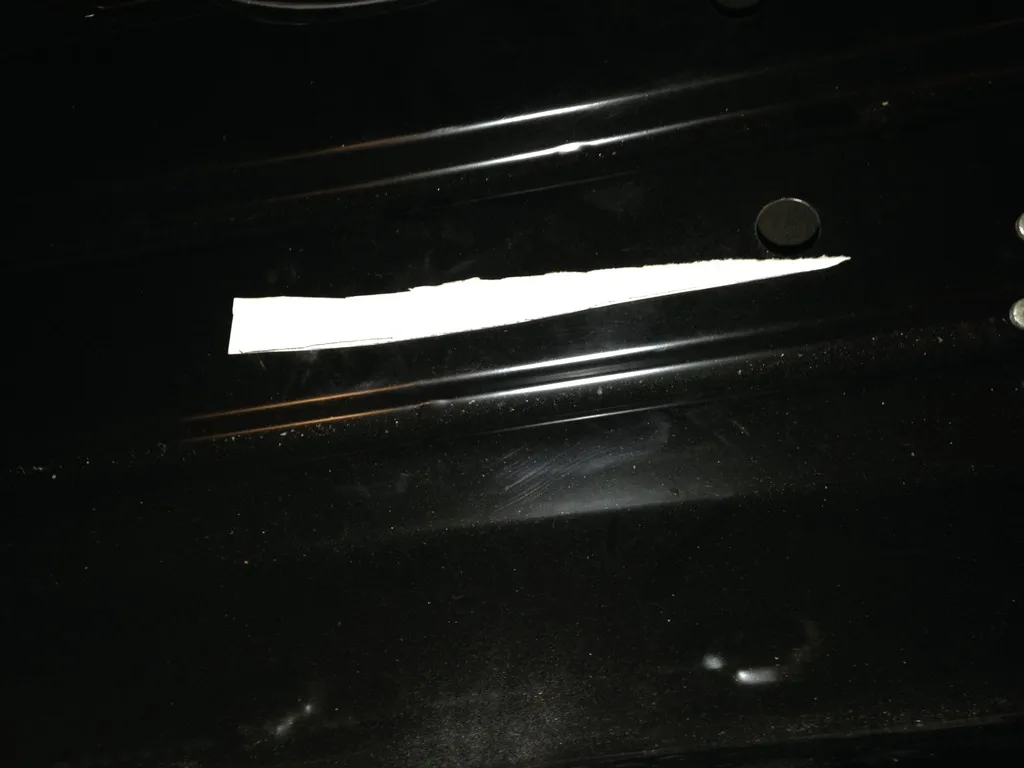

i did consider doing this but considering the boot floor is pretty solid and i didn't want to buy a new boot floor just to cut the front of the seat pan off. now it would also be harder for me to replace the whole panel as it is plug and seam welded to the heel board and i don't fancy the possibility of ruining the heel board. plus for some reason i like to make my life hard and accept challenges lol ![]()

![]()

Edited by James_eaton_thewholething, 30 July 2015 - 11:46 PM.

Posted 10 August 2015 - 09:15 PM

Posted 12 August 2015 - 04:38 PM

Posted 13 August 2015 - 10:16 PM

Good work James.

I am just about to tackle the same job on mine. I have already done one side so hopefully the other should be a doddle

0 members, 1 guests, 0 anonymous users