3D: The Perfect Bellmouth

#46

Posted 05 January 2015 - 11:55 AM

#47

Posted 05 January 2015 - 01:32 PM

Oh and a good radius is great for airflow but an ellipse will give you that bit more.

I know it maybe isn't the absolute ultimate shape but it if you have other ideas give us some clues, "an ellipse will give you that bit more" isn't a great help.

"

#48

Posted 05 January 2015 - 01:37 PM

Or instead of getting narky you could use your common sense to do some entry level research. Here you go, all warmed up and ready to be spoon fed.

#49

Posted 05 January 2015 - 02:42 PM

Who's getting narky?

I printed off Professor Blair's thesis on two-stroke design (here: http://www.dragonfly...trokeDesign.pdf ***Mahoosif PDF - 400 pages IIRC***) As I understand it David Vizard's bellmouth was an extension of his work, my 'design' is an extension of Vizard's.

#50

Posted 05 January 2015 - 06:00 PM

#51

Posted 05 January 2015 - 06:02 PM

Yeah that would be easy enough, but there would still need to be a modification as you cant get a tool in there to nip anything up as it stands

#52

Posted 05 January 2015 - 06:14 PM

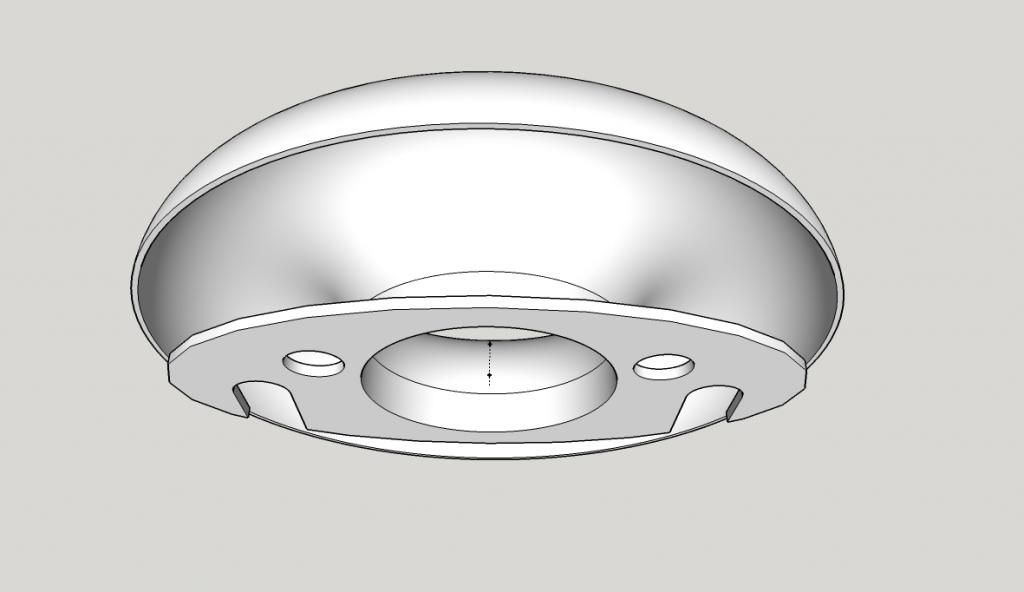

Could you design a way to slot the mounting holes so it could be slid under bolt heads and then nip them down to secure?

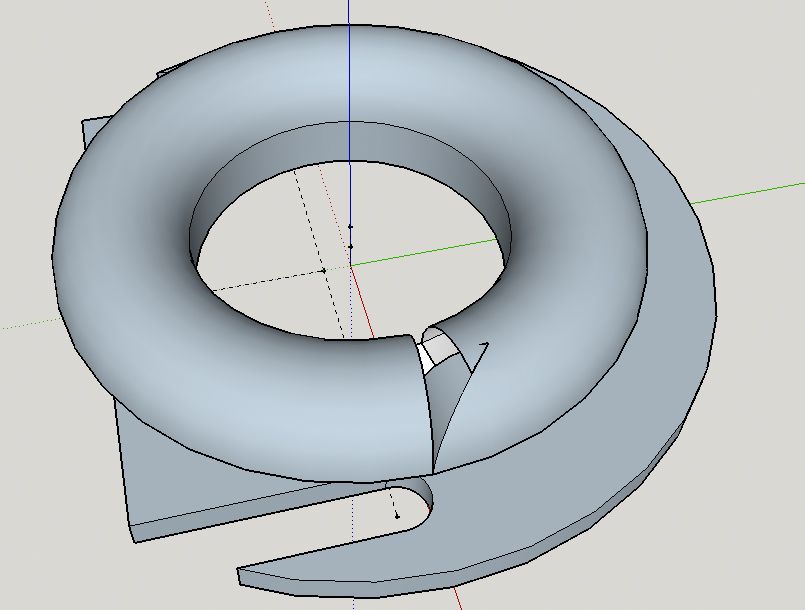

My first try was like that Graham:

It still has legs, we were going to slim a 1/2' spanner down for the job. Depending the new slim-bell works I might (have to) try that again.

#53

Posted 05 January 2015 - 06:15 PM

Yeah that would be easy enough, but there would still need to be a modification as you cant get a tool in there to nip anything up as it stands

Have you offered it up for fit to your 44 yet Alex?

#54

Posted 05 January 2015 - 06:17 PM

Yeah that would be easy enough, but there would still need to be a modification as you cant get a tool in there to nip anything up as it stands

Have you offered it up for fit to your 44 yet Alex?

Aha nope! been at uni all day today and had a presentation to finish for today, I will see if I can do it tonight when I get home or tomorrow as I am only at home tomorrow finishing an aerodynamics assignment

#55

Posted 05 January 2015 - 06:27 PM

Usually 3-4mm thick?

#56

Posted 05 January 2015 - 06:34 PM

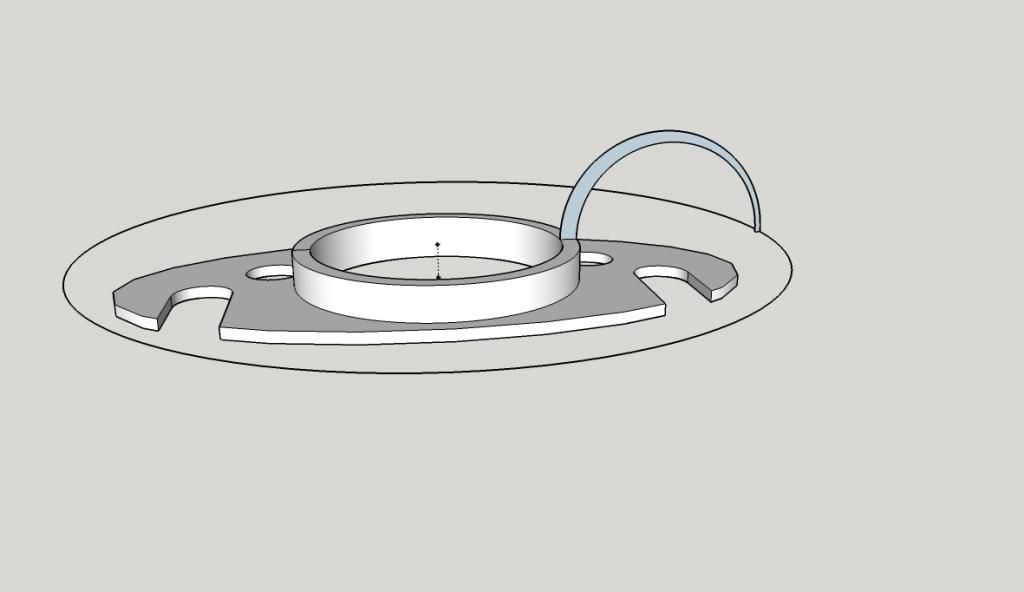

That version looks like there will be the same fitting issues, if it was me I would be making the trumpet longer to allow a spanner behind. Also watch out for clearance on the inner holes, on the one I printed there isn't any as the body of the bell intersected the hole due to the thickness mostly but a narrower throat would be an idea.

You run into clearance issues with the airbox, that's why I kept it so marginal. The newer design goes very thin at the edge, hopefully it'll deform enough to get fingers underneath.

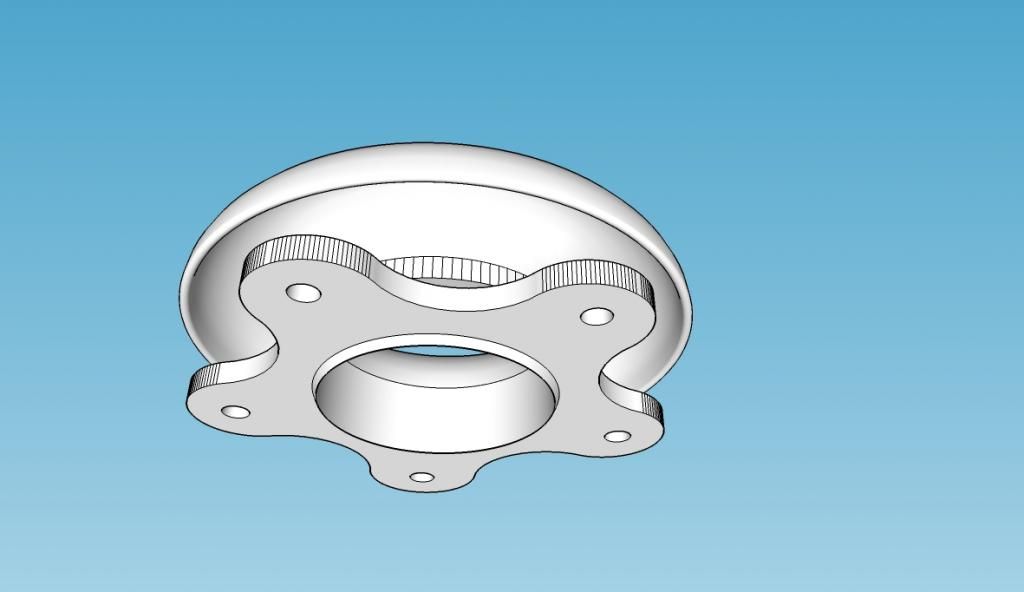

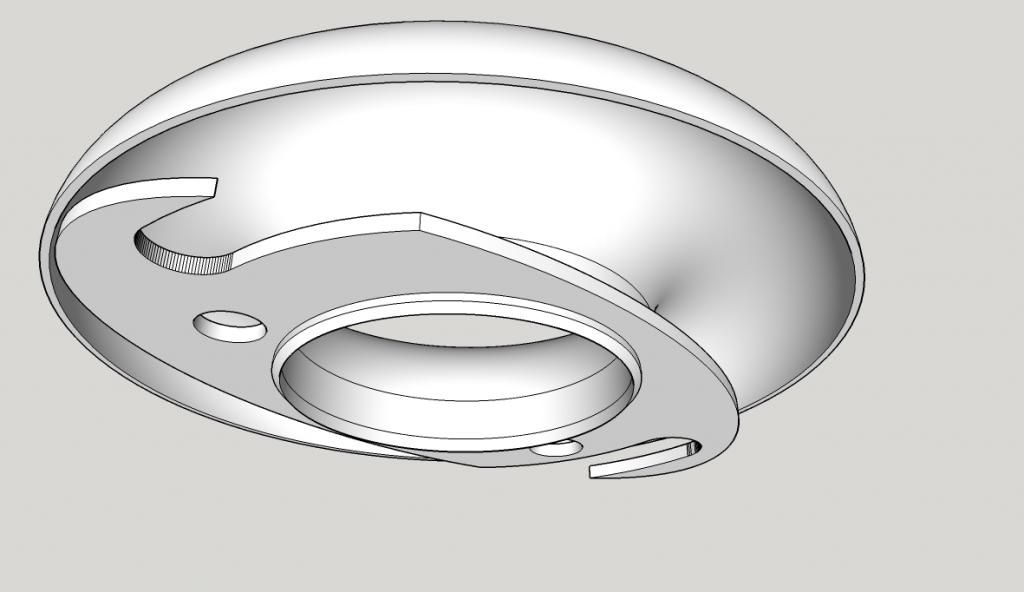

The thing is, you lose when you go longer, according to the yellow bible anyhoos. I've already done a longer, wider-throated trumpet for mounting on the outside of my virtual airbox, here it is:

It could be resized, redrawn, whatever.

This the latest Carb bellmouth, lots of midnight oil burnt last night, still not solid for printing though ![]()

#57

Posted 05 January 2015 - 06:51 PM

That version looks like there will be the same fitting issues, if it was me I would be making the trumpet longer to allow a spanner behind. Also watch out for clearance on the inner holes, on the one I printed there isn't any as the body of the bell intersected the hole due to the thickness mostly but a narrower throat would be an idea.

You run into clearance issues with the airbox, that's why I kept it so marginal. The newer design goes very thin at the edge, hopefully it'll deform enough to get fingers underneath.

The thing is, you lose when you go longer, according to the yellow bible anyhoos. I've already done a longer, wider-throated trumpet for mounting on the outside of my virtual airbox, here it is:

It could be resized, redrawn, whatever.

This the latest Carb bellmouth, lots of midnight oil burnt last night, still not solid for printing though

Is there any printable material that could withstand like 10 nm torque?

Captive nuts or similar might be an option too, I don't think these things should be torqued very hard..?

A kind of printed stud could work too if it owuld be printable?

Edited by Dusky, 05 January 2015 - 06:52 PM.

#58

Posted 05 January 2015 - 08:03 PM

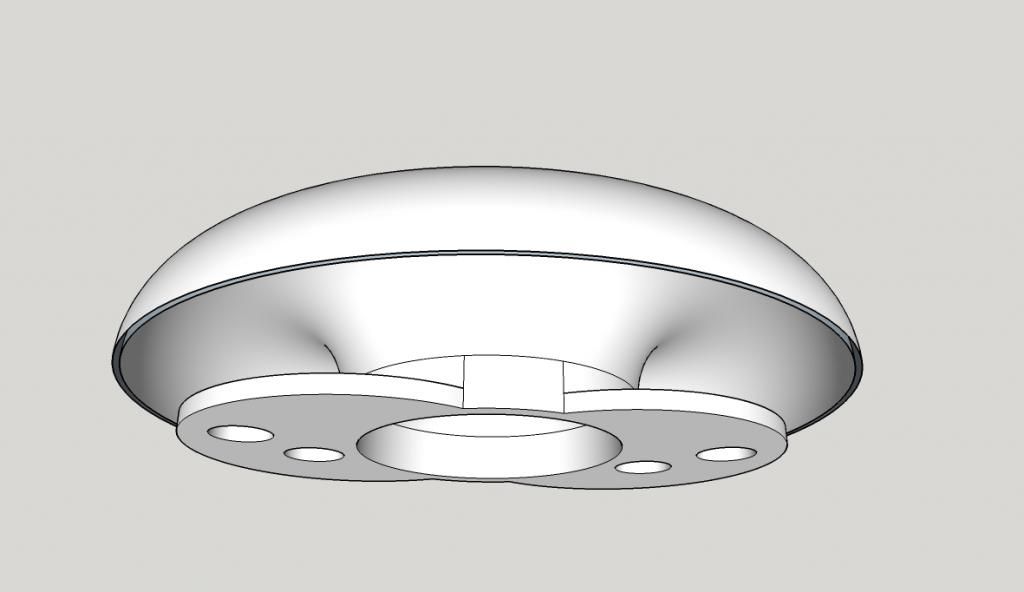

The new version is done. I scaled a circle into an ellipse, cut holes and slots out then extruded the whole lot by 2mm. Then I extruded the centre wall by and then drew the profile of the bellmouth:

A prod of the Follow Me tool and 5 seconds later I had it:

Solid for printing first time ![]()

#60

Posted 09 January 2015 - 09:27 AM

Updates!

Finally had some time to play with the print.

It fits!

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users