I like the MED bellmouth idea but Professor Pye wanted me to avoid it because of the air vent and mounting bolts on the face "we'll engineer one". In the meantime I bought the Pipercross bellmouth. According to Vizard's bible the intake will flow better than the Pipercross by 0.6% if it's a 'flat' bellmouth like the MED version.

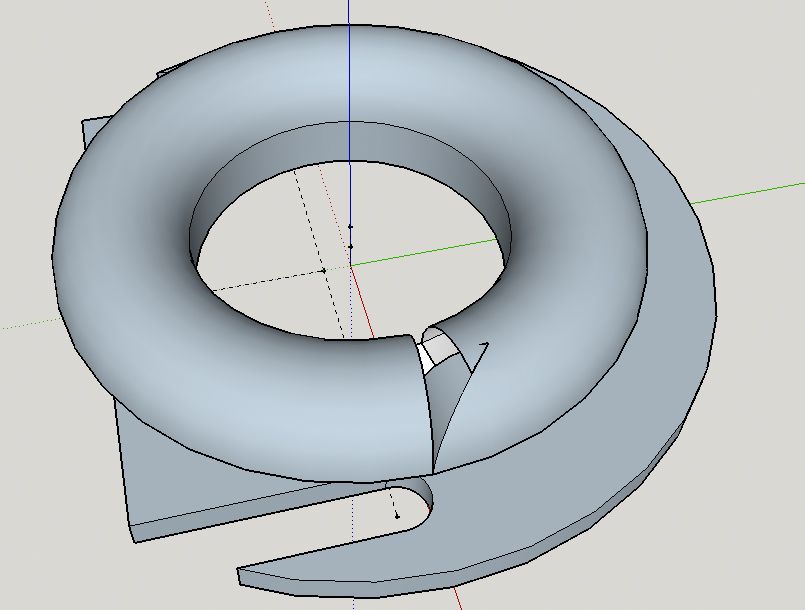

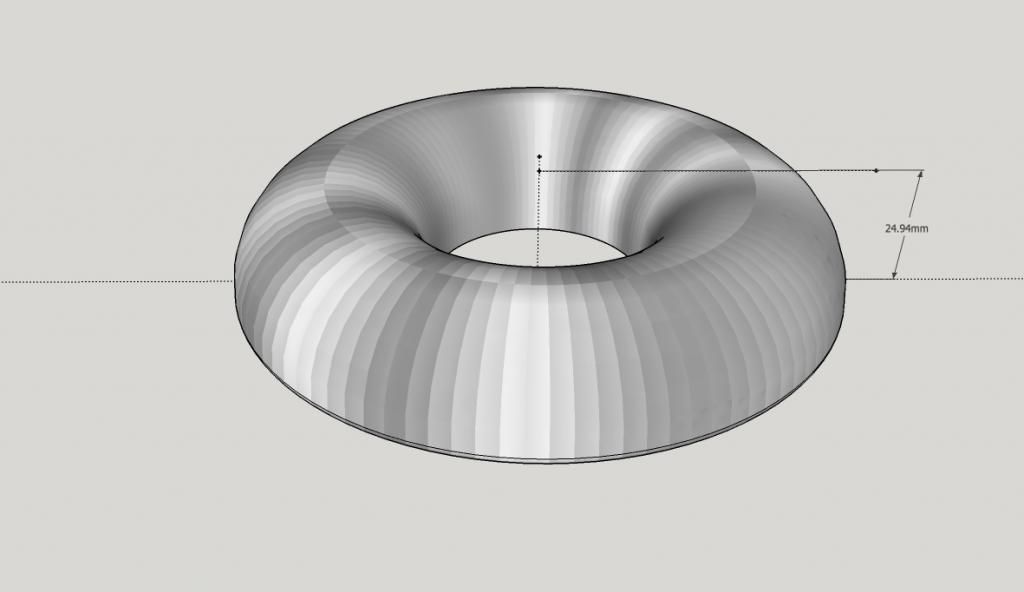

We'd been fiddling around with an airbox design for a while when I remembered an application called Sketchup. One night before xmas I started drawing a bellmouth [sub stack]:

It had a fatal flaw with the way I'd drawn it. It drove me to drink ![]()

I came back to it the next day and drew it again, and again,

and again,

and again,

and again,

and again...

It came back with the same result. ![]()

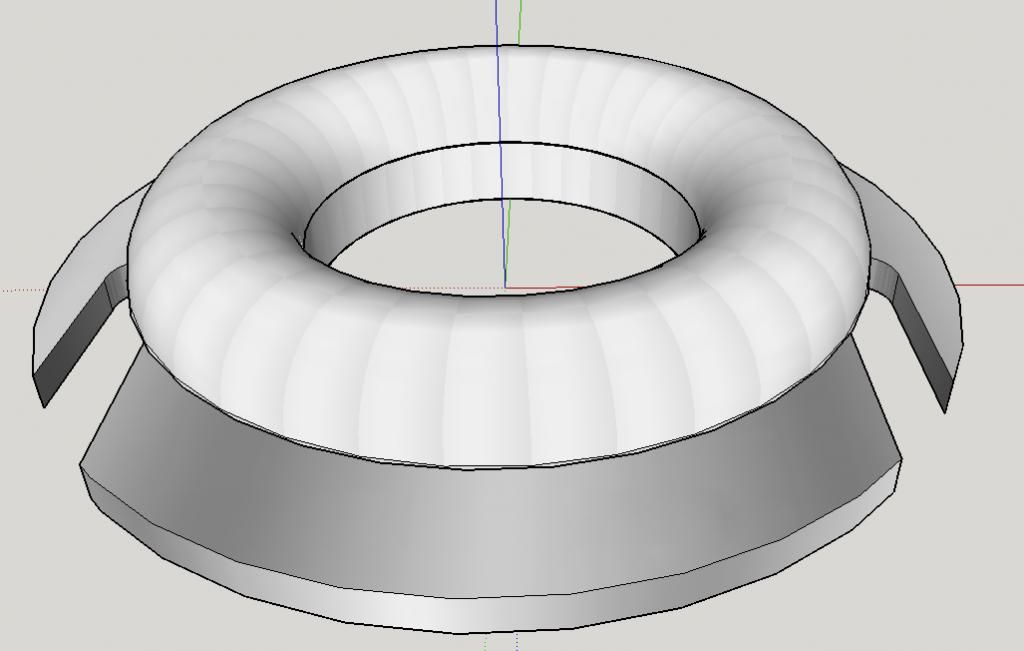

So I joined a Sketchup forum. After many naive questions I got a result:

I took it to Professor Pye, "It's too small, max out the width of the bell". So I measured up the size of the virtual airbox and went back to drawing it:

At about this time we thought of 3D printing it. We were muttering about this 3D printing malarkey when Sid rolled up at the shed and said his brother has a 3D printer!

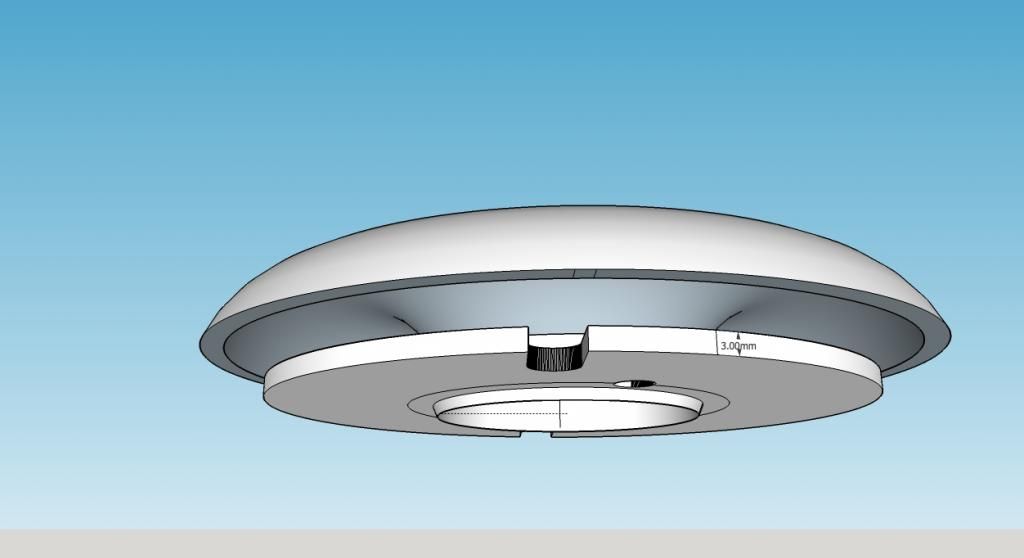

Only having the vaguest idea about the technique I went back to the Sketchup forum. I was told you have to put in support materials on overhangs on desktop printers. This really threw me, I'd have to put hundreds of supports in and around and under my beautiful bellmouth. ![]() Then I was told that if I went to a commercial powder printer they would just blow the support powder off, job done. So that was Sid's brother's desktop printer idea blown out of the water!

Then I was told that if I went to a commercial powder printer they would just blow the support powder off, job done. So that was Sid's brother's desktop printer idea blown out of the water! ![]()

After another 8 hours or so I'd nearly pulled my hair out ![]() trying to make the thing 'solid' for printing (coplanar surfaces, boolean differences, faceless edges etc.

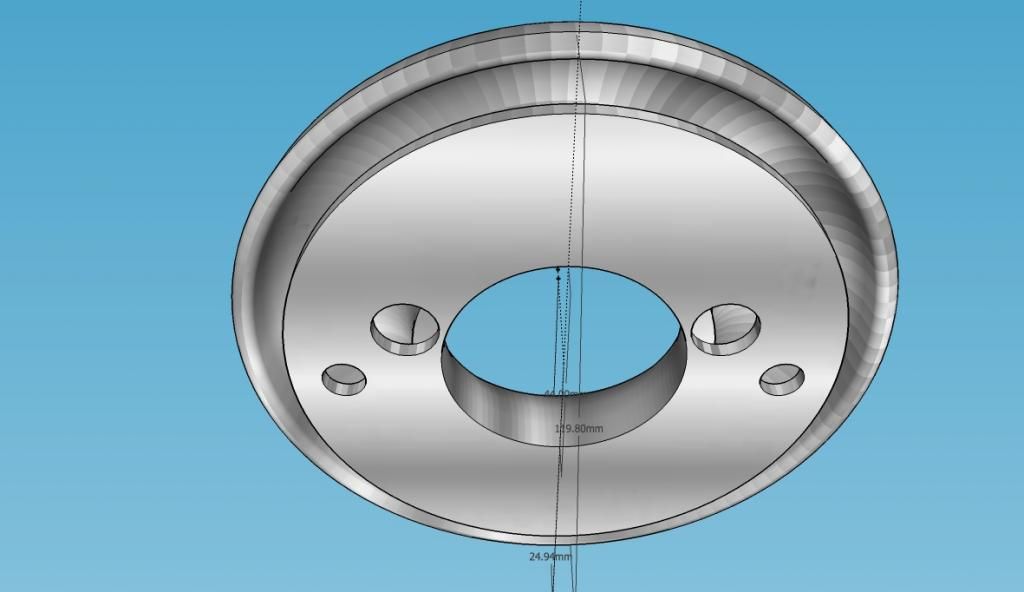

trying to make the thing 'solid' for printing (coplanar surfaces, boolean differences, faceless edges etc. ![]() ) trying to design in the mounting holes and vents I thought "balls to it, I'll machine the holes in afterwards" I was encouraged to design the holes in "The beauty of 3D printing is a finished model, straight off the printer."

) trying to design in the mounting holes and vents I thought "balls to it, I'll machine the holes in afterwards" I was encouraged to design the holes in "The beauty of 3D printing is a finished model, straight off the printer."

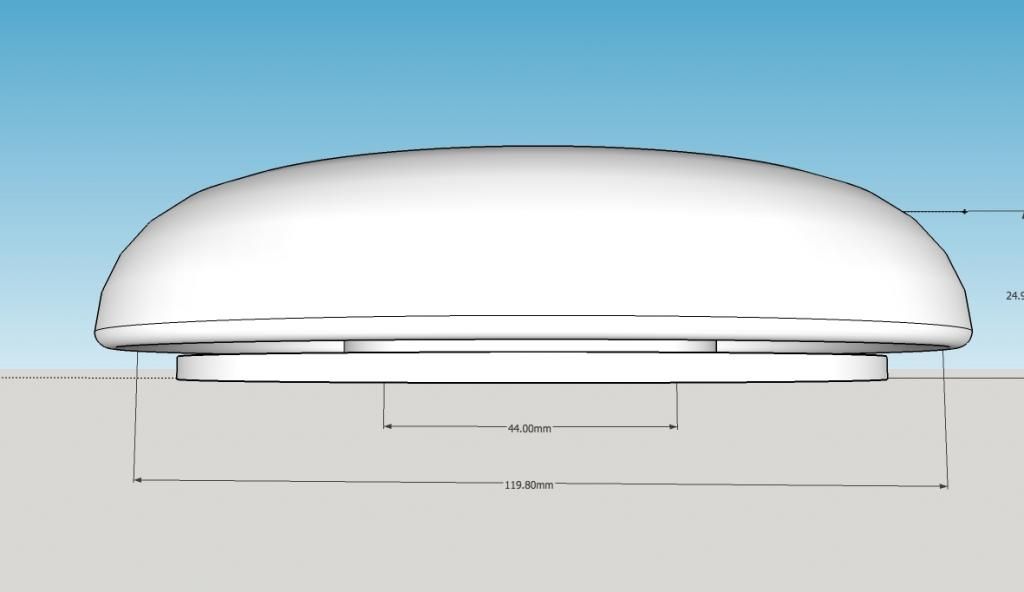

I went back to it and another 12 hours later (it's been a steep learning curve!) I have it:

I think it might be an absolute swine to fit, it all depends on how flexible 4mm thick printed ABS is??? I wonder if I need to do a version 12 with the bellmouth tapering down in thickness?...