Information Provided By Chris (Spider)

After carrying out tests of aftermarket Lucas Distributors currently available from different suppliers on his Distributor Test Bed. Highlighting the difference in Advance Curves and where they differ from the manufactures Specification. This article is primarily about the remanufactured one Distributor fits all 850-1275

This is an Exhaust Valve I pulled from the head of an 1100 engine about a year ago

It kinda looks like it's been oxy cut. It also cracked the head.

The owner is a reasonably sedate driver in that while he would keep up with surrounding traffic, he wasn't one for ringing each and every gear out either.

The distributor fitted was for a 998 engine.

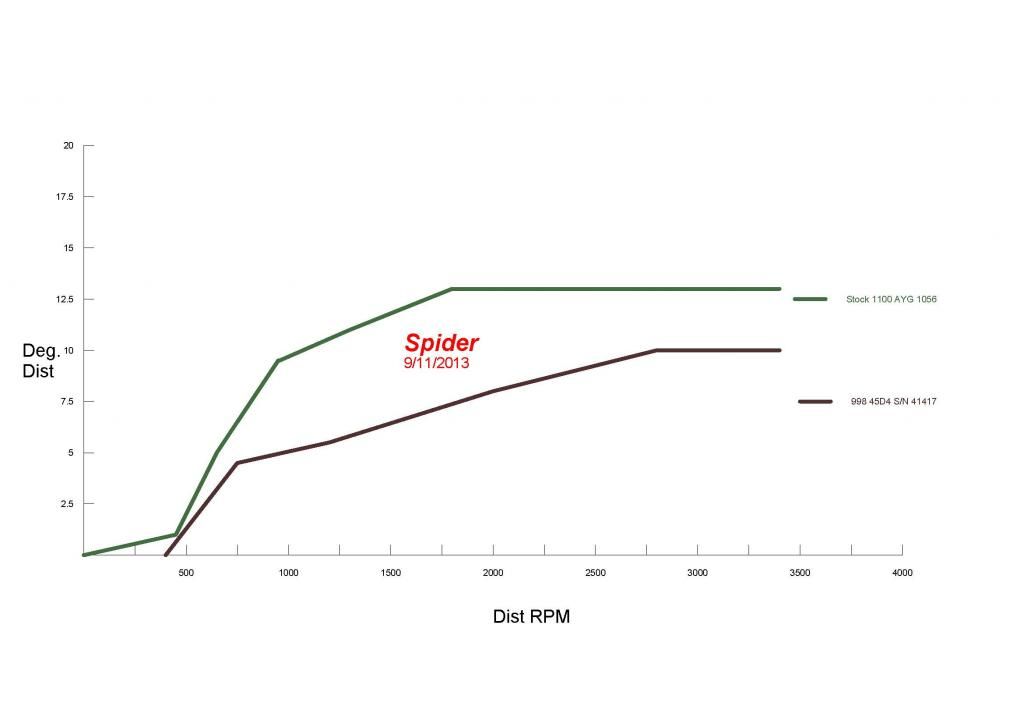

When the Advance Curve of what should be fitted is compared to what was fitted, the reason for the badly burnt valve starts to become clearer

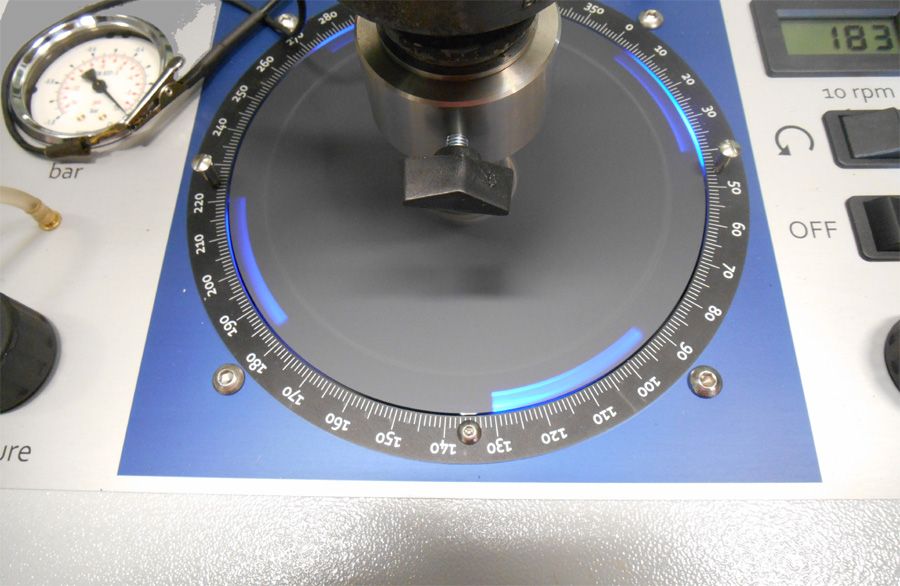

( a shot of the disc from my dissy tester)

The RPMs and Degrees Advanced in that Graph ^ are at the distributor, so you need to multiply them by 2 for what's going on at the crank.

Looking at the graph, what is clear is that right around 'the normal cruising zone' from 2000 to about 4000 RPMs, the required Ignition timing was quite retarded. Driving with it in this state causes very hot gases to go through the exhaust as the fuel is still burning (or not long finished) as the exhaust valve starts to open, causing the burning of the valve. If it were from a lean mixture, then the valve would have a white appearance.

Note too that this particular distributor, as fitted, doesn't have a Vacuum Advance either, which in this case, could have helped.

This shows why the correct advance curve is important and just one example of serious engine damage.

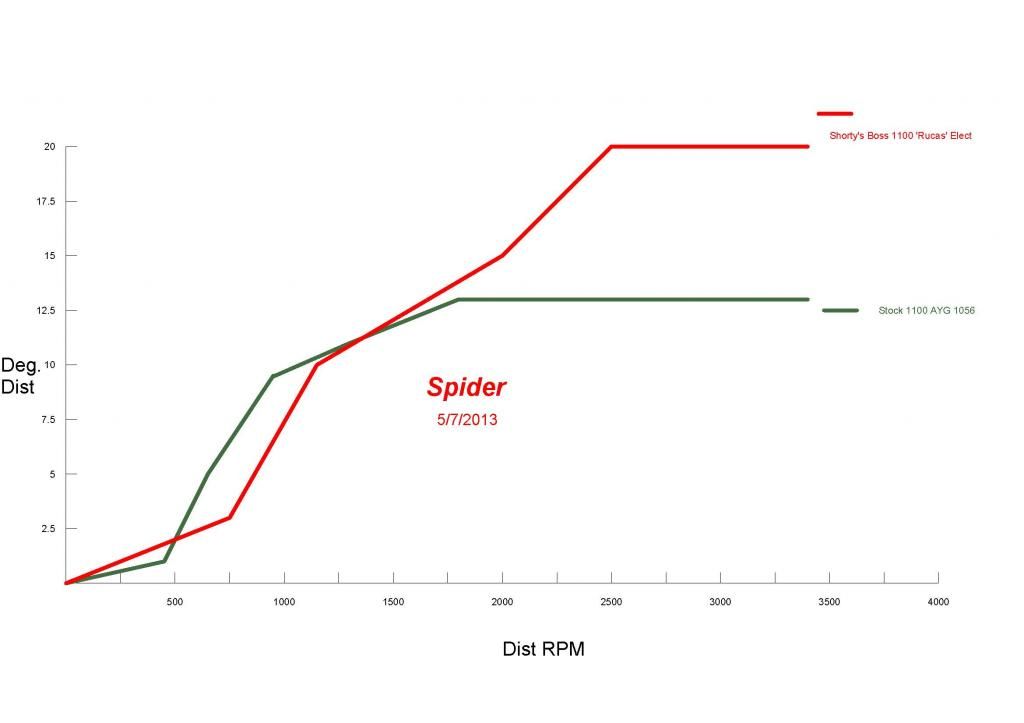

Just coming to the Lucas Copies that seem to be popping up on ebay and other places these days, most of these don't seem to have a stated Advance Curve. I've been able to test around 30 of these now and no 2 have been the same. I've seen some very wild figures from these as well, in one case

Now, remember that is in Distributor Degrees, so that is a total of 40 degrees at the crank + about 6 degrees static, way too much for any A Series Engine I know of!

Yes, it was fitted to an engine and it only survived around 2500 km before it too was damaged, in this case, the owner was fitting a Primary Gear Seal about every 2nd day, after a quick check to show him that his fresh engine had some serious blow-by, it was pulled down. We found that the ring lands on the pistons were hammered down, pinching the rings.

From the tests I've done on these copies, there doesn't seem to be any rhyme or reason to them, they are just a lucky dip.

So, I'd suggest when buying any of these new distributors, asking what the Advance Curve is. If they simply say, "Suits from 850 to 1275 Engines", then I'd suggest you study the above carefully, if you do have to purchase one as yours is beyond a overhaul, then I suggest to speak to AC Dodd here on the Forum or H&H Ignitions who can re-curve it to suit.

If your In NSW then Moke Spider can also advise and no doubt sort you out.