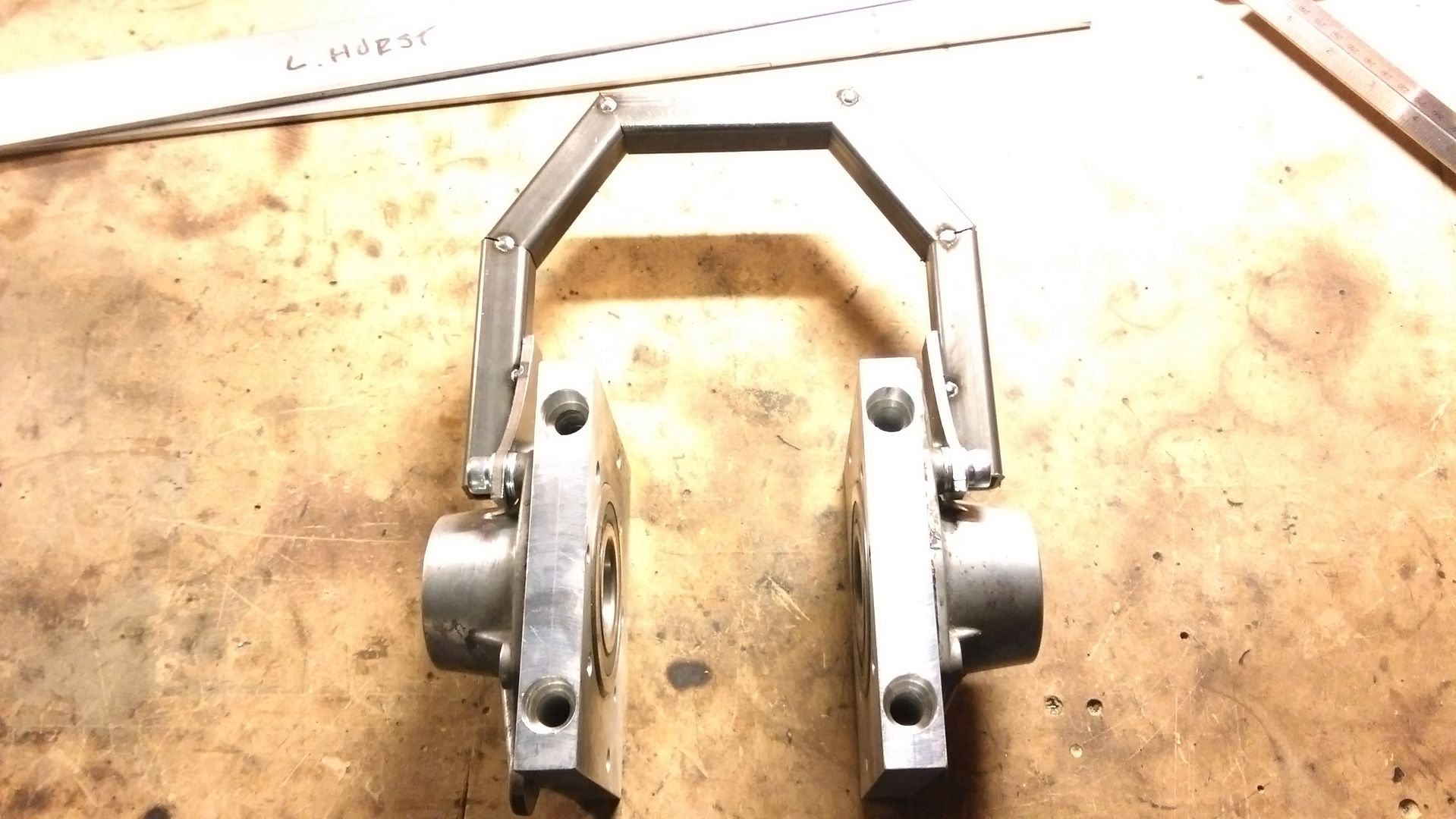

Engine craddle MK2 is born!!

I started on Saturday and finished it this morn (Sun). It's all new except the rear most piece that I salvaged from the old one. I much happier with the build of this one, especially the main backbone which is now much neater and a better design than the last.

The left hand upright looks unfinsihed where it attaches to the subframe mount but I still have another piece to add that will tie into it effectively capping the end of the box section.

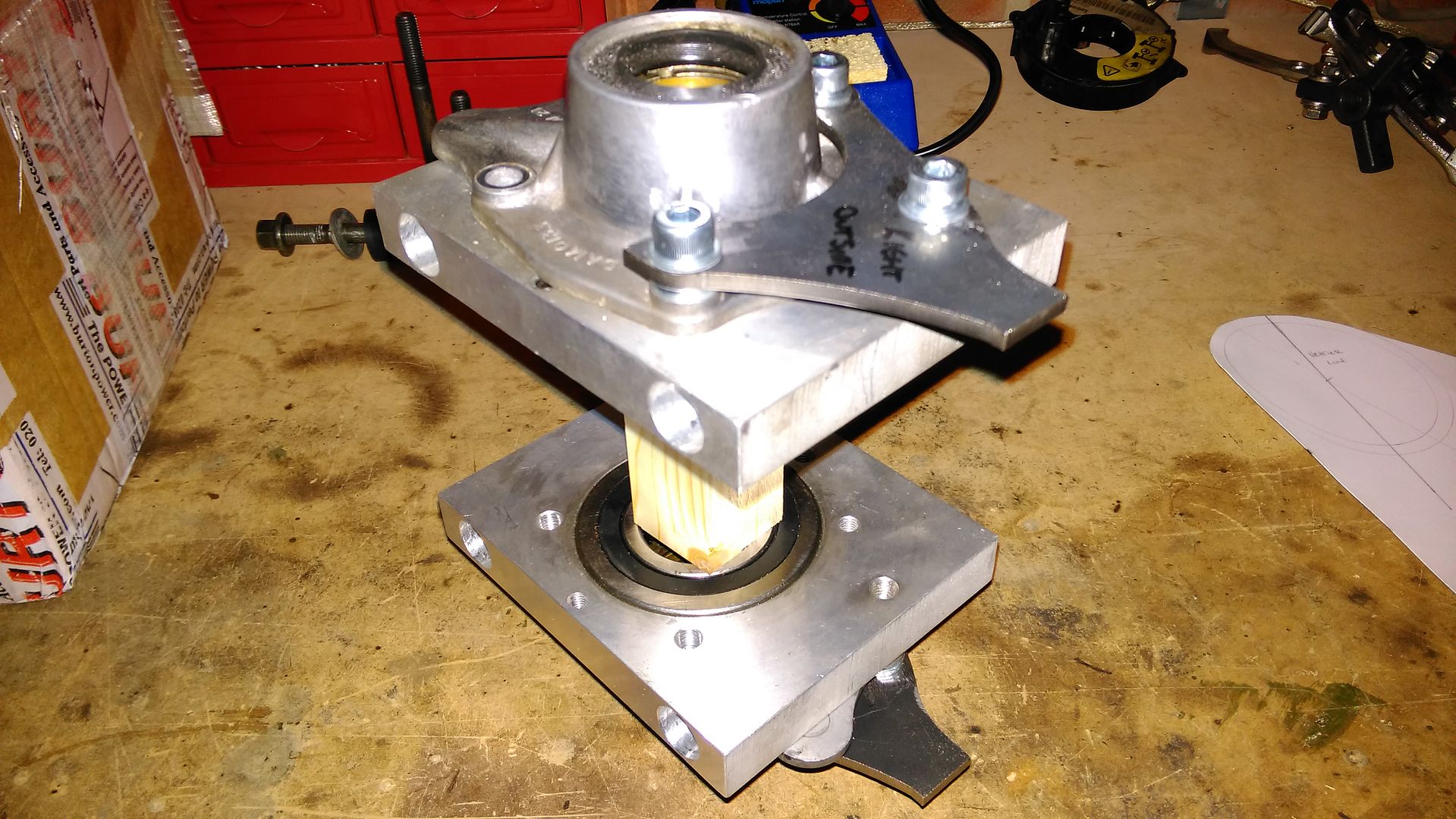

I determined the engine height (30mm higher than previous) relative to the subframe by referencing a number of pictures of completed builds. I could see that the bottom of the oil cooler bolt was slightly lower than the top of the front cross-member on the subframe. The left-to-right position is the same as before and the front to back position is roughly the same as before albeit a few mm further foward. I've also picked the front of the engin up slightly so that the engine leans back. This will hopefully help gain a few mm of clearance at the front for the exhaust.

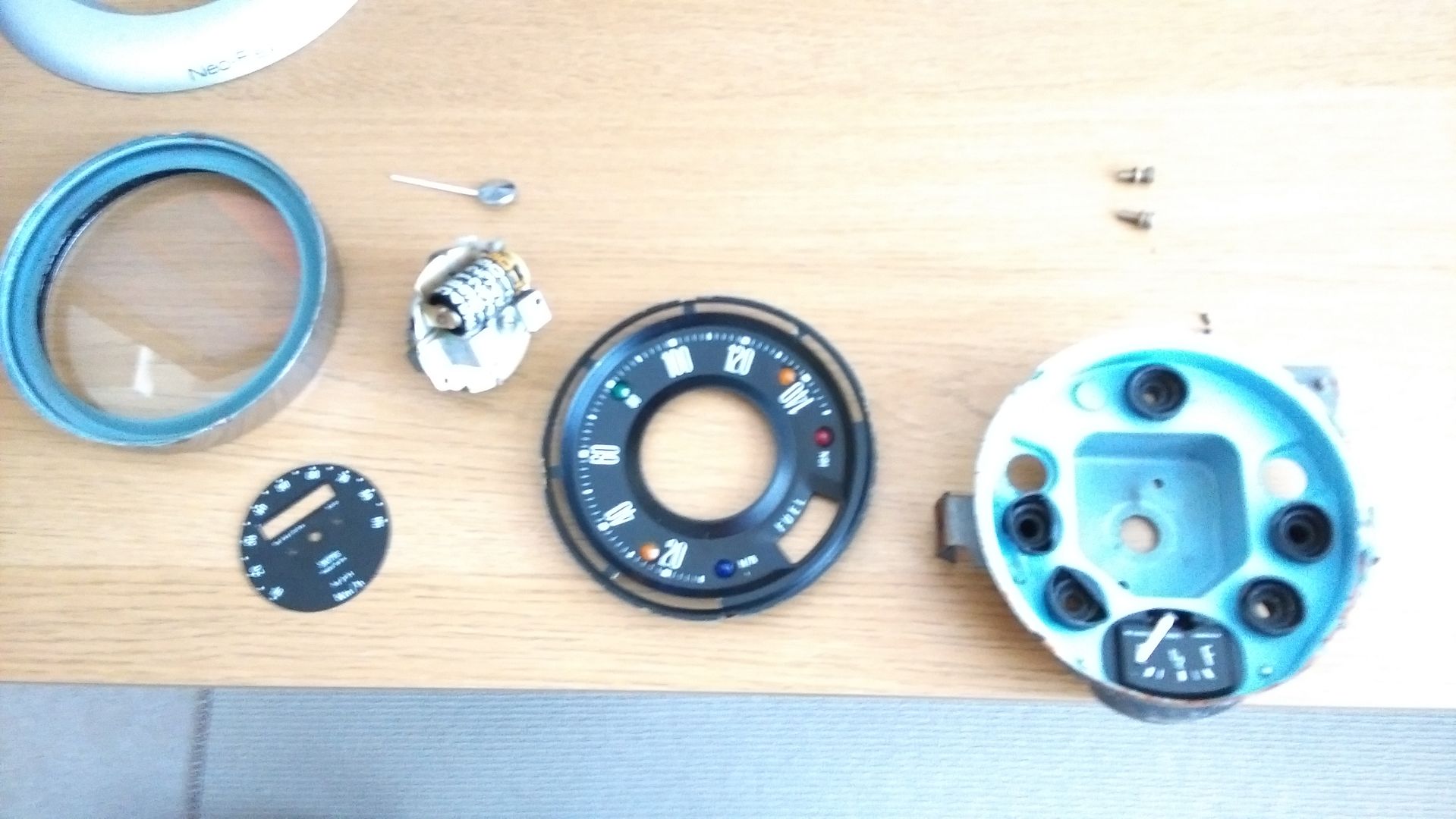

I'm now roughly back to where I was before I realised the craddle needed to change and it's only taken a weekend plus £10 worth of materials. My custom diff hanger brackets have arrived from the laser cutters so I can get on with fabricating the bracket next.