Cooper Mpi Restoration - My Second Mini Project

#76

Posted 15 May 2015 - 07:45 AM

Now I too should have 70mph @ 6500rpm - 123mph equates to 11400rpm I have calculated. Heading to Mallory Park on thursday so will verify with some GPS data.

#77

Posted 15 May 2015 - 01:03 PM

That is the same gearing I have just upped my pro-motive kit too. It was too short before and revved way past peak bhp in 6th.

Now I too should have 70mph @ 6500rpm - 123mph equates to 11400rpm I have calculated. Heading to Mallory Park on thursday so will verify with some GPS data.

Will be interested to find out how you get on. I've never been in an R1 mini so have no idea what I'm letting myself into. I've had sports bikes so I know what the high revving bike engine is like just not in a car.

Mallory is brilliant circuit imo. I used to race push bikes there when I grew up in Leicester.

Luke.

#78

Posted 16 May 2015 - 09:46 AM

#79

Posted 16 May 2015 - 10:12 AM

That sound ![]()

I bet your ears were ringing for ages after!

#80

Posted 16 May 2015 - 10:14 AM

Duds good reactions

What did you improve on the pro motive for track use?

#81

Posted 16 May 2015 - 04:36 PM

Mallory has a really good variation in height with a fairly long straight and huge sweeping bend to carry speed. the hairpin is epic. Very tight and more like a carousel.

I can't wait to get mine on the road. I'm thinking I'll be at least another year though.

Edited by LukeH, 16 May 2015 - 04:37 PM.

#82

Posted 16 May 2015 - 11:00 PM

#83

Posted 18 May 2015 - 11:20 AM

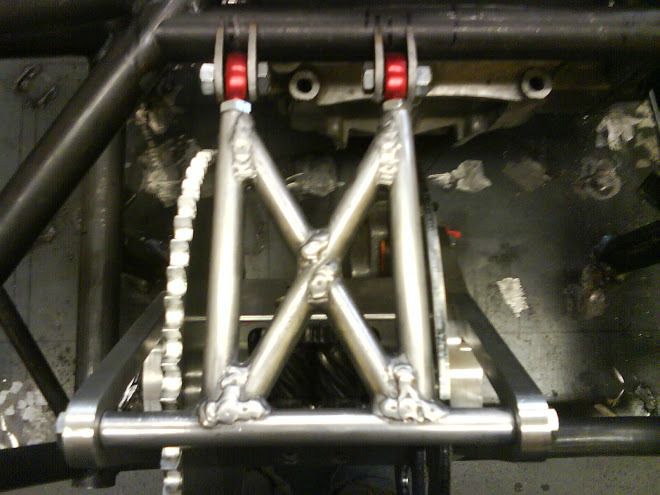

I have confirmation that my differential kit is under construction this week so I am giving some serious thought to how I am going to mount it on the cradle and more importantly how I am going to tension the chain.

My current thinking is some sort of swing arm mount like a motorbike rear wheel swing arm with an adjustable rose jointed tensioner. I'm wondering whether I could use a front upper suspension arm bearing/axle as the main mount or whether I should just use rose joints throughout.

This is going to be a tricky thing to get right and I feel a few prototypes on the way.....

#85

Posted 26 May 2015 - 01:56 PM

I received an email from Douglas at Westgarage today letting me know that the diff kit is almost complete and should be with me very soon.

I haven't done much on the project since the last update due to spending time, and money preparing my XC race bike for a mountain bike race in a couple of weeks. I managed to stuff the rear shock during a training ride which has lightened my wallet considerably to replace it. It's tricky balancing cycling with restoring a car at times.

#86

Posted 27 May 2015 - 01:04 PM

Looking forward to seeing what the diff kit looks like - hopefully it holds oil better than mine does! Mallory was really fun by the way - you were right!

#87

Posted 27 May 2015 - 02:06 PM

Looking forward to seeing what the diff kit looks like - hopefully it holds oil better than mine does! Mallory was really fun by the way - you were right!

Glad you enjoyed it. Did you capture any video footage?

#88

Posted 27 May 2015 - 02:28 PM

Edited by duds100, 27 May 2015 - 02:28 PM.

#89

Posted 03 June 2015 - 07:47 AM

I will need to build it up once I have purchased a differential, output shafts and other misc gaskets and washers.

This particular kit uses standard mini output shaft covers and gaskets so servicing should be straightforward.

#90

Posted 30 September 2015 - 08:31 PM

No pictures but I made a few changes to the craddle a couple of nights ago and I've ordered some more steel to collect this Friday.

I was thinking for a little while to scrap my homebuild and buy a promotive kit but then I discovered they aren't making them anymore.

Anyway, I willl start posting pics of progress again for those of you who care to see them.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users