Cooper Mpi Restoration - My Second Mini Project

#46

Posted 13 March 2015 - 05:39 PM

#47

Posted 13 March 2015 - 06:47 PM

Could you not remove the front wheels and then prop the car up so it is level as if the wheels were fitted?

Should be simple enough to measure from the top of the wheel arch to the ground with the car at rest on it's wheels and then match the measurement when propping it with the wheels off.

Might give you enough room to get the hoist under the front that way?

Thats a fair point to make. I will need to find something to use rather than my axle stands as they are too tall even on the lowest setting but makes more sense to do what you've suggested.

#48

Posted 14 March 2015 - 05:58 AM

I have some 6x6" Oak blocks which come in handy for that sort of thing. They were offcuts from when i made my work bench

#49

Posted 14 March 2015 - 08:31 AM

#50

Posted 14 March 2015 - 04:51 PM

I took Ben_O advice and got the car propped up on blocks of wood at the ride height if wheels were fitted. This enabled me to get the engine crane under the car and close enough to lift the engine in for the first time.

I spent quite a bit of time measuring everything up to determine the engine position.

Next I lifted it out of the way and made a start on the cradle. I angled the first upright away from the engine towards the o/s inner wing to clear the engine.

Next I used a straight edge and magnetic level to square everything up. The next upright was positioned to be vertical. This will go up to the horizontal piece that crosses the back of the engine over to the nearside.

Thats all for now. I haven't got loads done but its a start.

Edited by LukeH, 14 March 2015 - 04:54 PM.

#51

Posted 15 March 2015 - 08:40 PM

Looks like a good start to me!

#52

Posted 16 March 2015 - 08:30 PM

Good start indeed!

#53

Posted 19 March 2015 - 12:34 PM

I think I am going to redo the bits I've just done on the cradle to improve the gaps and change the angle slightly.

My biggest challenge with this project is going to be overcoming my desire for perfection. I'm never happy with the finish and always want to redo things.

#54

Posted 20 March 2015 - 08:48 PM

Done yesterday all the changes to subframe which are needed for the Lynx kit, everywhere just mm space....hurts to chop up a perfect subframe but needed to fit the R1 in.

Would recommend to get your diff already now as you need that to properly position your engine.

Keep rockin

#55

Posted 21 March 2015 - 10:18 PM

Looks like a good start. Yes overcome your perfection and just weld your cradle roughly together, you will redo it anyhow 3 or 4 times as it is very tight everywhere.

Done yesterday all the changes to subframe which are needed for the Lynx kit, everywhere just mm space....hurts to chop up a perfect subframe but needed to fit the R1 in.

Would recommend to get your diff already now as you need that to properly position your engine.

Keep rockin

I know what you mean about it being tight. The engine seems small in a bike until you try and squeeze it into a mini engine bay.

I agree about getting the diff. I've got the funds but was holding off ordering until I had determined I could make the cradle myself. Its going ok so far so I'll think I'll get it ordered. Not sure what sprocket size to go for?

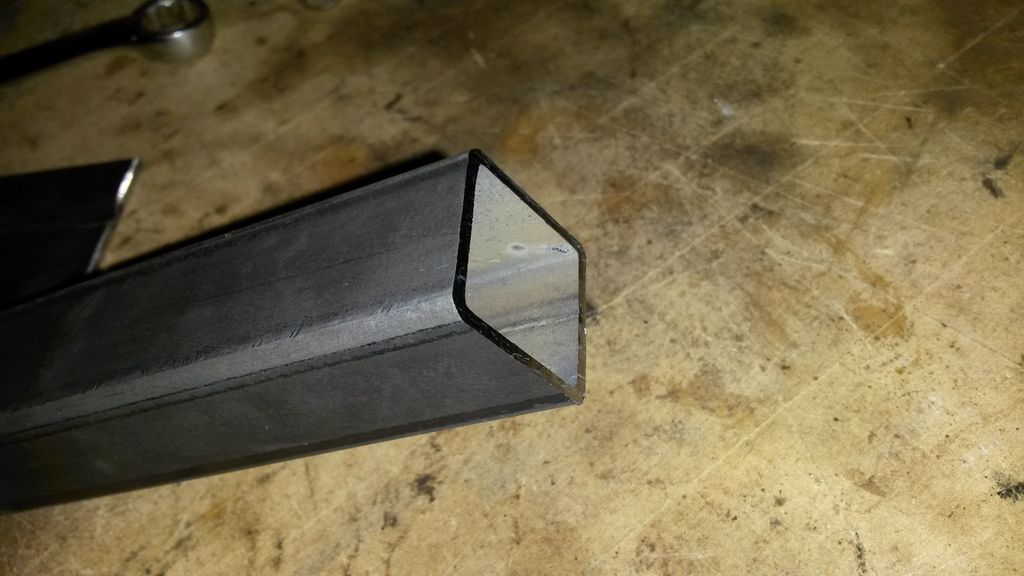

I borrowed my brothers metal chop saw today. My god it makes light work of cutting. 20-30 seconds for a perfect cut through the box section.

#57

Posted 22 March 2015 - 04:50 PM

Hope that helps.

Yes good tools simply and speeds up work enormously.

#58

Posted 23 March 2015 - 04:05 PM

#59

Posted 27 March 2015 - 11:53 AM

What to use as front sprocket depends on the sprocket on the diff. So 14 to 56 is 1:4 ratio which is best for 10inch, for 13 inch rims a 1:4,5 ratio is best from BEC experience I was told, so with a 13 sprocket front and 56 diff that fits. But in this combination you won't find a chain that fits bold on, you have to buy a long 530 and take some pieces out to shorten it to the right length. As 12 inch is closer to 10 then 13 I would try a 1:4 ratio.Cheers. I have 12's at the moment but I am planning on 10's so I will have to work out the best ratio for that.

Regards your engine position: the gear change must be directly at the angle when the straight piece finishes and curve begins, means you need to move it min 2cm forward to be able to fit the diff. Was working exactly on this yesterday and needed to chop more of the front of the subframe to create the necessary space for oil to water cooler, water pipe and oil filter. So from the u- shape is just a I-shape left on 50cm length where exhaust till water/oil cooler sit. Not really happy with this but no other chance to make it fit....And it looks I need to lift the engine every time I need to change the oilfilter as there is not enough space on mine, not acceptable as this will happen quite often.

R1 engine is part of motorbikes structure so it stiffens up the front and compensates the loss on the front bar.

Edited by Helldriver, 27 March 2015 - 12:03 PM.

#60

Posted 27 March 2015 - 12:15 PM

What to use as front sprocket depends on the sprocket on the diff. So 14 to 56 is 1:4 ratio which is best for 10inch, for 13 inch rims a 1:4,5 ratio is best from BEC experience I was told, so with a 12 sprocket front and 56 diff that fits. But in this combination you won't find a chain that fits bold on, you have to buy a long 530 and take some pieces out to shorten it to the right length.Cheers. I have 12's at the moment but I am planning on 10's so I will have to work out the best ratio for that.

Regards your engine position: the gear change must be directly at the angle when the straight piece finishes and curve begins, means you need to move it min 2cm forward to be able to fit the diff. Was working exactly on this yesterday and needed to chop more of the front of the subframe to create the necessary space for oil to water cooler, water pipe and oil filter. So from the u- shape is just a I-shape left on 50cm length where exhaust till water/oil cooler sit. Not really happy with this but no other chance to make it fit....And it looks I need to lift the engine every time I need to change the oilfilter as there is not enough space on mine, not acceptable as this will happen quite often.

R1 engine is part of motorbikes structure so it stiffens up the front and compensates the loss on the front bar.

As ever, thanks for providing the useful information. I thought I would end up having to shorten a chain so I'm not that worried about that although I hope I don't regret saying that!

I'm not quite sure what you are referencing about the gear change angle but I am not in front of the engine at the moment so hopefully it will make more sense when I can see it. If not I might ask you to provide a couple of pictures if that isn't too much trouble?

Regarding the front of the subframe. I have actually cut the front cross member out to allow ease of access during cradle fabrication. I will of course add a cross member back in but will probably go with a small profile square tube and alter the position to better accommodate the oil/water outlets and exhaust.

My current plan is to fabricate enough of the cradle to allow the engine to be held in place relative to bonnet, front cross member, rear bulkhead etc...then lift the whole lot including the subframe, purchase the diff and exhaust manifold and then complete the cradle fabrication. I figure there isn't much point in building a cradle only to discover the exhaust doesn't fit by 5mm!

Cheers, Luke.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users