Sounds like you're moving right along! I'm no help on the subframe questions as I'll be using a Lynx kit. Keep posting pictures :)

Yeah progress is going fairly well at the moment and I'm keen to get stuck in whilst the enthusiasm is high despite the near freezing temps in my garage ( a new heater is on the list).

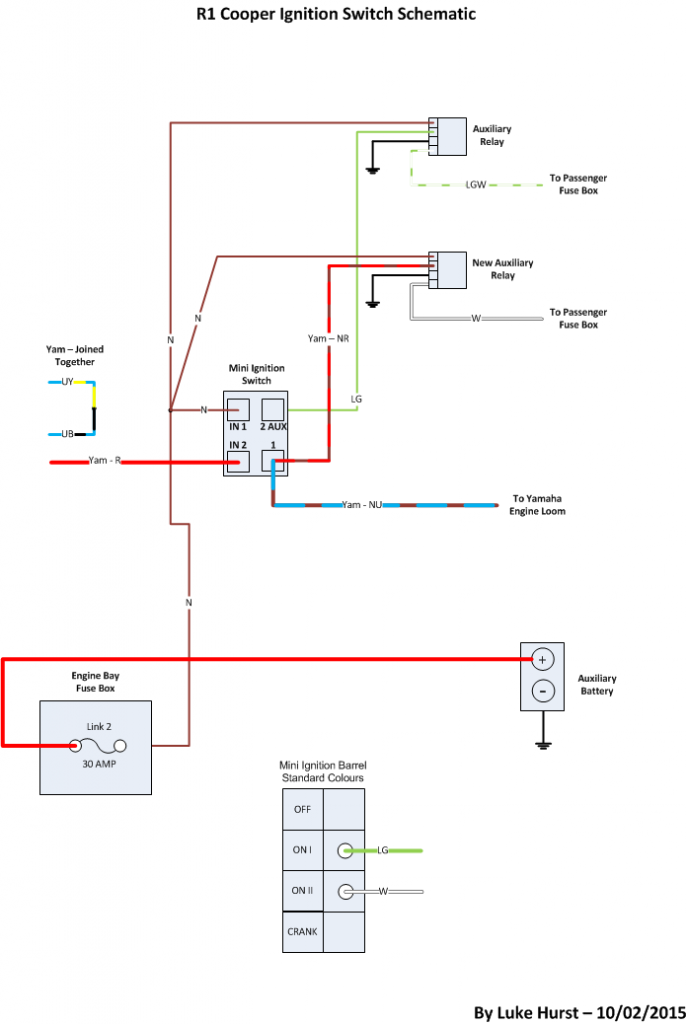

The new toggle switches and relays arrived today so I will get a picture of those posted up. I've also bought a batch of riv-nuts to redo the headlight bowls and to run the internal battery cables.

Next on my purchase list is a small sheet of carbon fibre to make a switch panel to match my carbon centre binnacle.

Edited by LukeH, 13 February 2015 - 03:15 PM.