Welded up all the holes in the engine bay ready for a clean minimal look. Gen Heritage Scuttle (one of the few panels I wouldn't replace with cheaper alternative) tacked ready for fibreglass/carbon fibre front end, once I know it all lines up ok, I will plug weld it up.

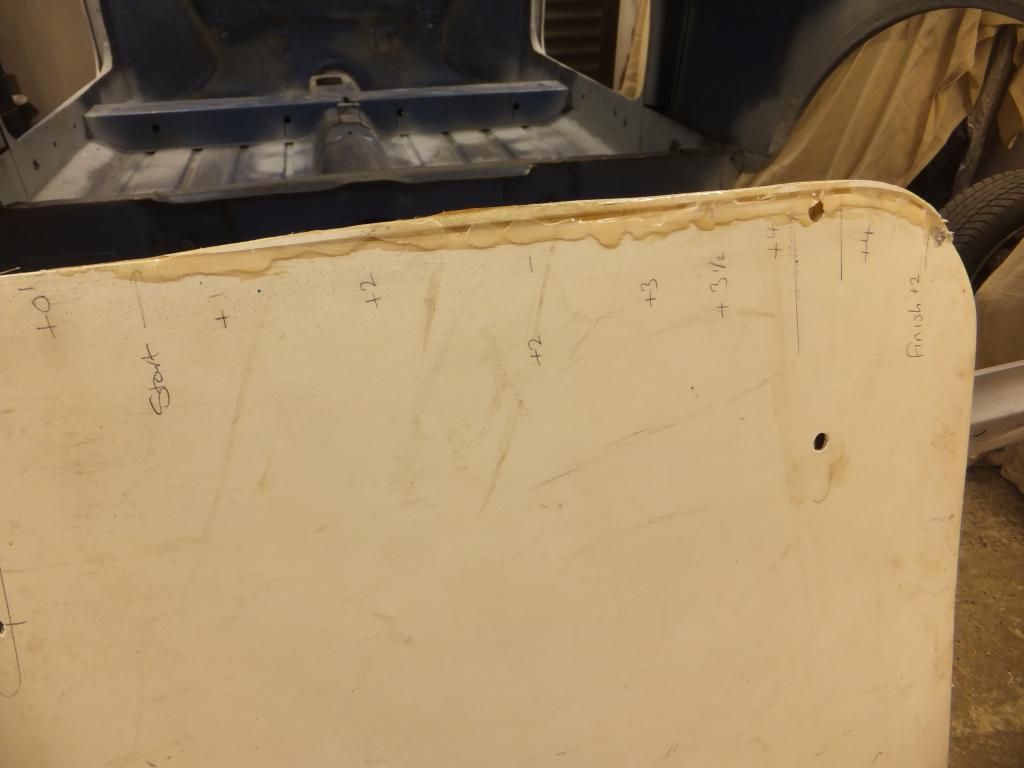

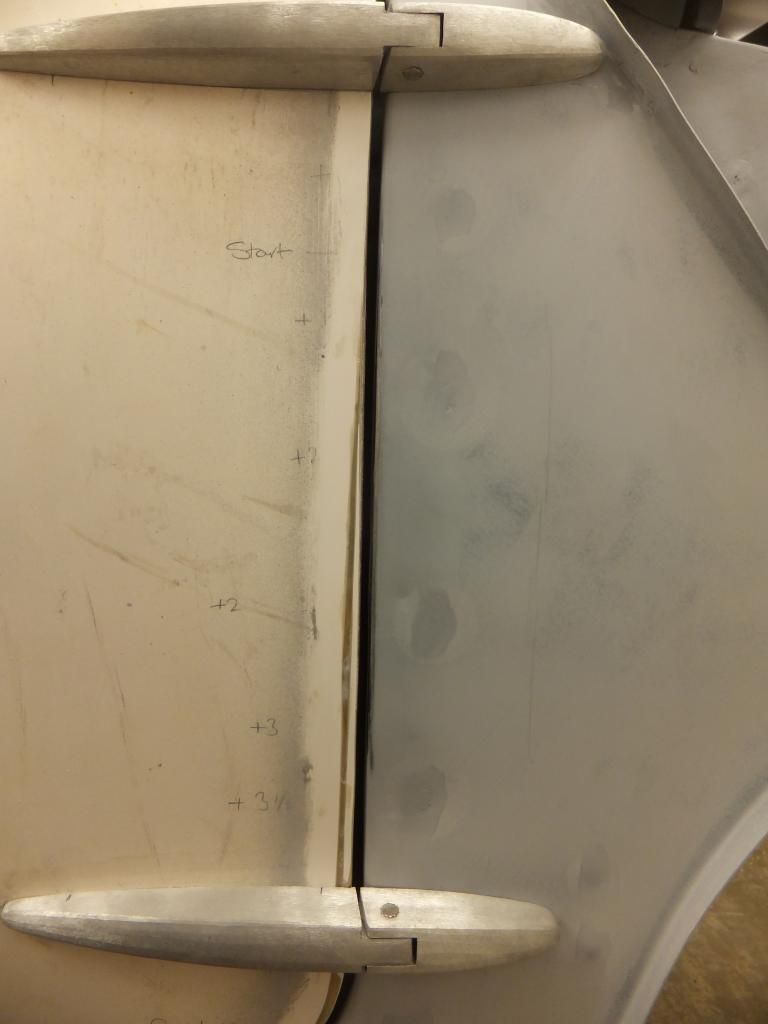

Mk1 A panel and hinges offered up on N/S and fitted. Took my time getting all the gaps right and am fairly happy with the result, albeit these doors are a bit of a pig to fit right, took plenty of trimming and sanding and being mk3 doors I have to modify the edge that meets the A panels substantially. (ask me if I would use them again once I'm done!)

Taking a lightweight approach and in an effort not to pile in layers of mild steel like the original inner panels which would down the line cause potential rust problems I fabricated some simple channel hinge reinforcement pieces.

Using Jenolite I treated all the suspect areas in the engine bay and the seams and a couple other places on the car, the shell is mostly good as I only rebuilt it 6 years or so ago.

Engine bay in Primer, I have been rubbing/sanding through to bare metal and using a Epoxy primer with anti corrosion properties. I'm told its good stuff, not too expensive and it goes on great!

One finished, one to go, got to be easier right?..?

That's all the photos for now, I was a bit more confident second time round and to cut a story short....I trimmed the second door too much, 4mm too much. So its currently in the garage having had the piece I cut off fibreglassed back on. First time using fibreglass so we will see how this holds out, it certainly looks the part but will soon tell when I start trimming it back again hopefully tomorrow evening :)