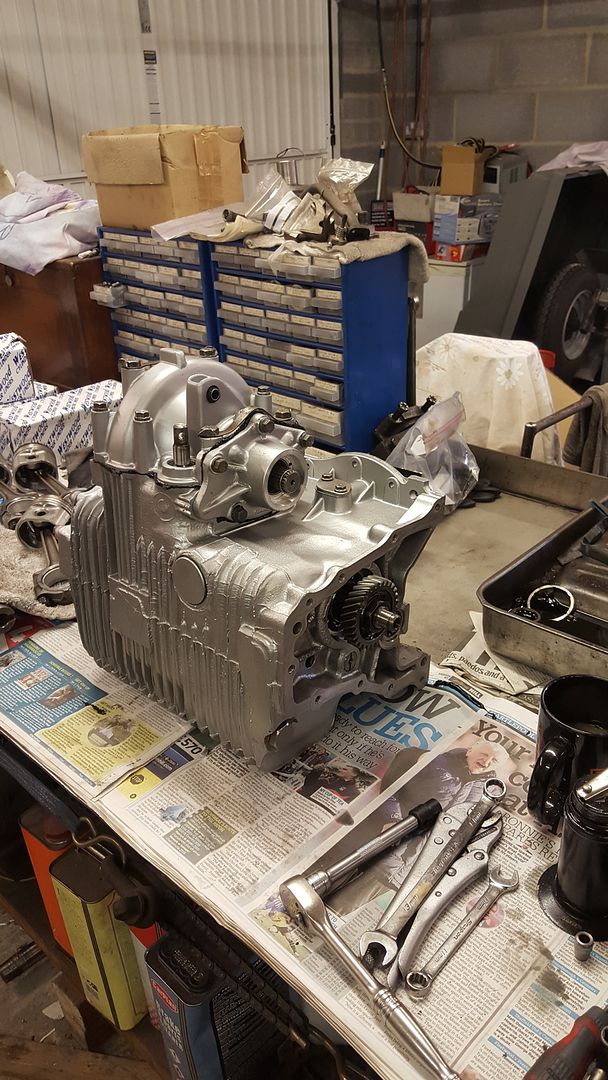

So the first engine club of the new year and the time has come to re-build the gear box.

The first decision was which final drive the gearbox would have. As I live in Milton Keynes and have a lot of 60 & 70 MPH speed limits on the roads the decision was to go for a 3.44:1 crown wheel and pinion as opposed to the 3.1:1 already installed and change the primary gear to an economy one. This means the engine will have a drop gear ratio of 0.9666:1 giving a final drive ratio of 3.32:1. This will give a good balance of acceleration/cruising RPM, at 70MPH the car should be doing around 3900RPM.

New crown wheel and pinion and primary gear.

First up was to remove the diff side plates followed by the diff case and diff. As I will be installing a new X-pin diff the existing unit was not inspected for wear. During the strip down three trays were used for the components, one for the casings/diff, one for gears/bolts/ect and one for all worn parts. The diff side plates were checked for play using a pot joint. One side was ok but the other had too much play and will be replaced. Next up the speedo drive and housing were removed and the gearbox placed on its end to allow the remaining oil to drain out (while I put the kettle on).

In the above picture the idler gear has also been removed. This was inspected and has worn on both shafts so will have to be replaced (see picture below).

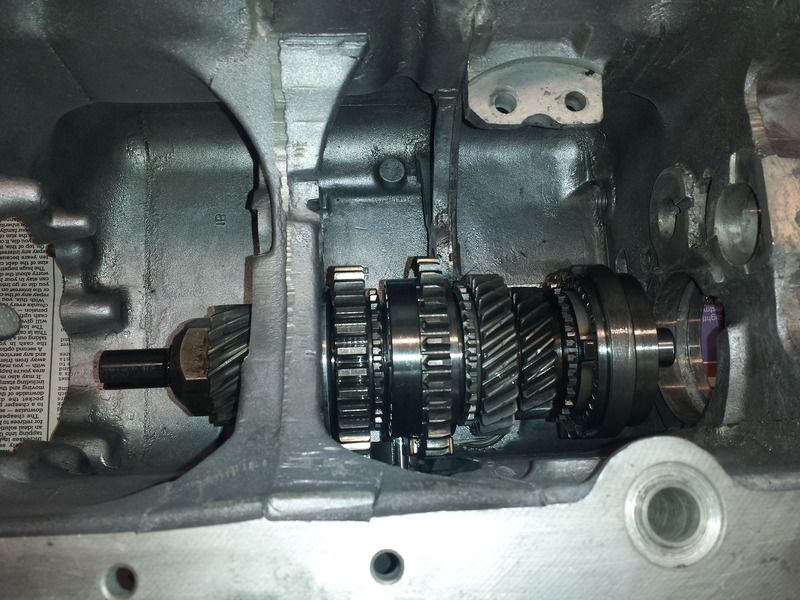

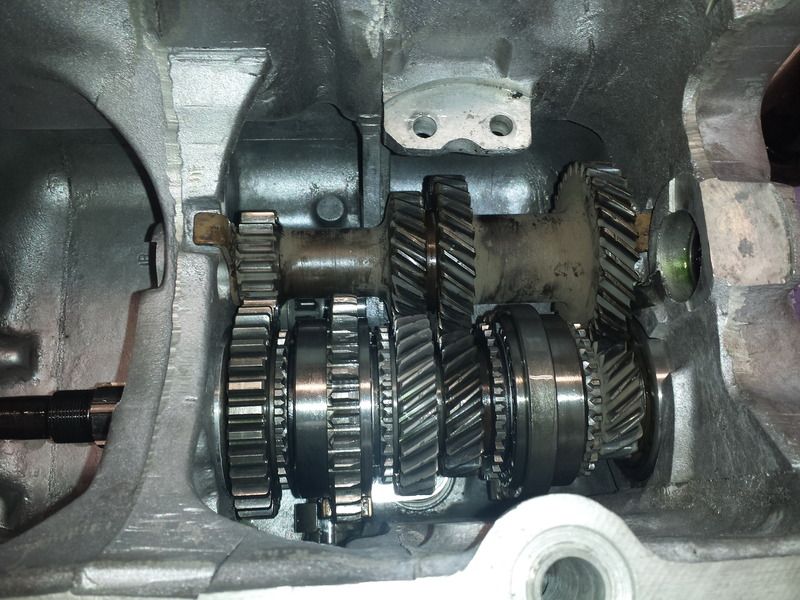

Next up was to remove the oil pick up pipe, this wont be getting re-used as a central oil pick up will be fitted. With this out the way the gear box was locked in first and fourth gear by pushing the 1st/2nd synchro hub to the left and 3rd/4th synchro hub to the right (first disengaging the gear selector). With this done the input gear circlip was removed followed by the bearing rollers and cage. The bearing centre could then be prised off using two tyre leavers. Each roller was inspected for wear and then reassembled. Next up the lock tabs were knocked back and the input gear removed followed my the main shaft nut and bearing retainer plate. With this done the layshaft could be pushed out allowing the gears to be rolled up and out of the box. The reverse gear could then also be removed along with the oil strainer. Using the tyre leavers again the input gear was removed from the third motion shaft. The two main bearings was then drifted out which allowed the main gears to be removed (making sure to hole both ends of the gears on the shaft as they are removed to avoid parts of the syncro hubs ending up all over the place).

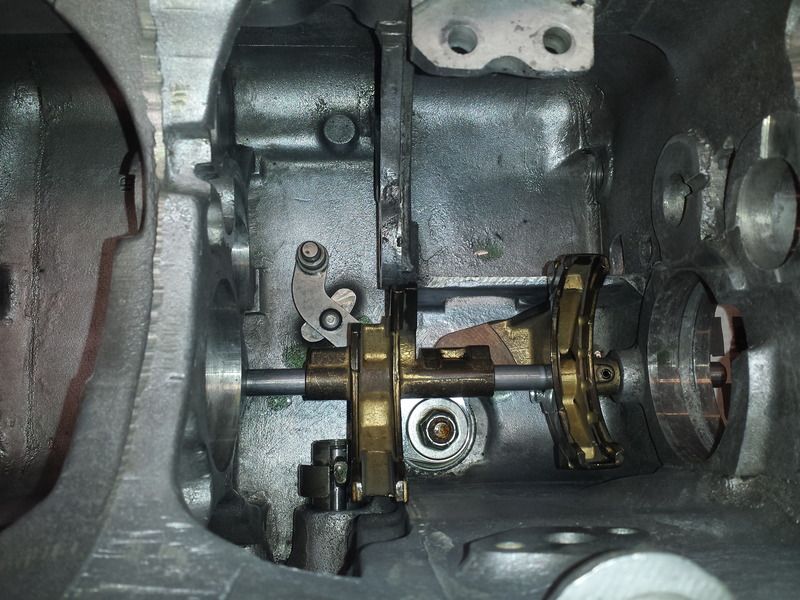

This just left the gear selector roll pin to be drifted out and the shaft and forks to be removed (being carful not to let the forks slide too far to the left and bend the shaft). After this the rest of the selector mechanism was removed.

The last part to remove from the box was the idler gear. The case was heated around the bearing using a propane torch and the bearing was then knocked out using a socket.

Empty case ready for cleaning

Gearbox components ready for cleaning

Casings and old diff

With everything apart it was time to clean down all the tools and inspect the parts for wear. The gearbox case was all fine with all threads intact (more checks will be done once all clean). It was then onto removing the gears from the third motion shaft. Upon removing the gears the second gear idler and 1st/2nd syncro hub both had too much wear and will have to be replaced.

Tray of attrition

So at this time for the rebuild I will be using the following parts:

- A+ gearbox rebuild kit less diff parts

- 1st/2nd syncro hub (2nd hand)

- 2nd gear idler (2nd hand)

- Diff side plate

- Centre oil pick up pipe

- Idler gear (2nd hand)

- Mini Spares X-pin diff

- Diff bearings

- Syncro springs

- 2nd hand 3.44:1 crown wheel and pinion

- Diff crown wheel bush

- 2nd hand economy primary gear

- Primary gear front and rear bushes

- New genuine baulk rings