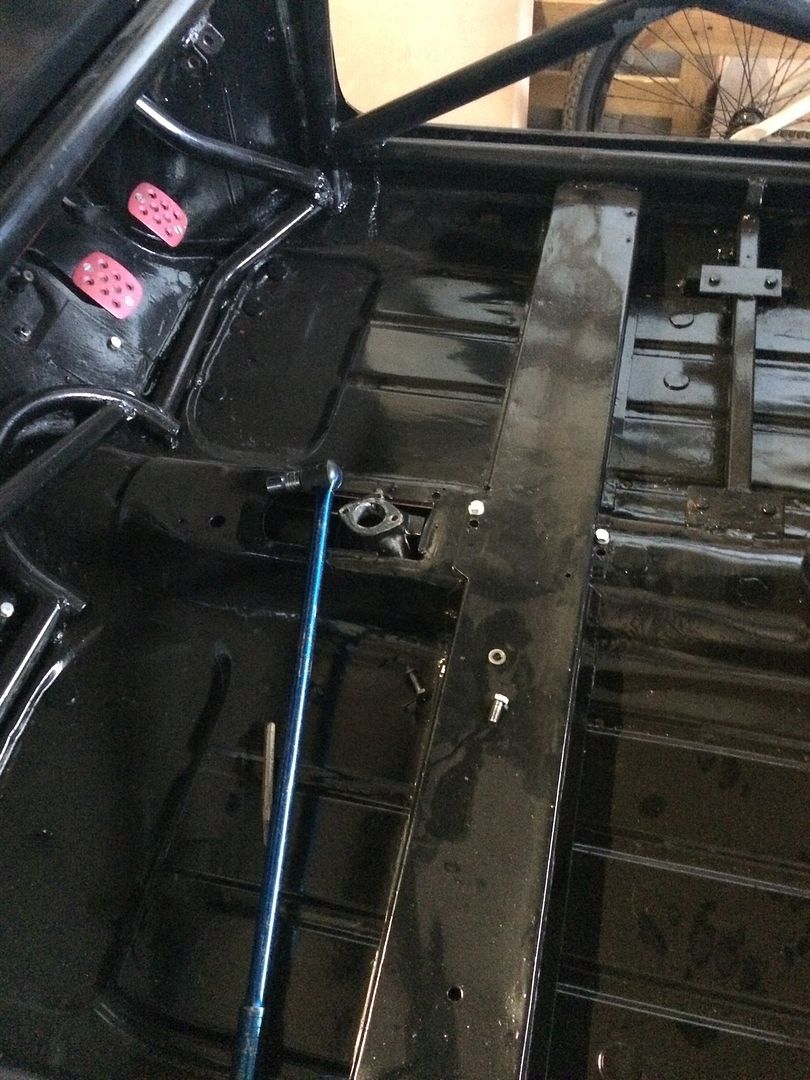

Gear lhouding attached and mounted. Silghtly odd in that it did not want to fit on the holes I made last time. Might have mounted it in a different hole on the bracket.

Posted 16 May 2015 - 06:30 PM

Looks like a superbly designed diffuser if you ask me.

Or maybe it's a blue print for a 3 column bridge?

Posted 16 May 2015 - 10:10 PM

Posted 23 May 2015 - 08:15 PM

Floors looking good! Are you planning to calculate the aero benefits of it or just by the seat of your pants?

Posted 23 May 2015 - 08:52 PM

Posted 23 May 2015 - 08:56 PM

Claculate? Not got the wind tunnel or the CAD model to run in the software.

But just using some basic rules and known behaviour. I should end up with a better result than before.

The front is kinda the hardest as it does need to be easy to remove but yet still work with the front air dam.

The rear and side will be simpler just requiring bent sheet alloy. The cost there is the bending and the welding after the cardboard models.

Gotta model it and run it through CFD, half the fun of it! ![]()

Posted 23 May 2015 - 09:27 PM

Gotta model it and run it through CFD, half the fun of it!Claculate? Not got the wind tunnel or the CAD model to run in the software.

But just using some basic rules and known behaviour. I should end up with a better result than before.

The front is kinda the hardest as it does need to be easy to remove but yet still work with the front air dam.

The rear and side will be simpler just requiring bent sheet alloy. The cost there is the bending and the welding after the cardboard models.

Posted 24 May 2015 - 05:27 PM

Very snazzy indeed.

I've always thought it'd be interesting to work up an aero kit and do back to back test with and without it at a practise day.

Posted 25 May 2015 - 06:54 PM

Looking good! Was wondering what alternator setup you using with the front mounted rad?

Projects →

Mini Saloons →

Mini Cooper Project - Finally StartsStarted by piphatch , 08 Jan 2025 |

|

|

||

Projects →

Mini Saloons →

1965 Austin Mini Restoration - Canadian Mk1Started by DoubleEh , 14 Nov 2022 |

|

|

||

Projects →

Mini Saloons →

Project Joe - 1991 Mini Mayfair 998Started by Eggers , 02 Jun 2022 |

|

|

||

Projects →

Mini Saloons →

Mpi Dashboad ProblemStarted by mikeprez , 22 Dec 2021 |

|

|

||

Projects →

Mini Saloons →

1978 Oew - Willy The MiniStarted by smalltreegrower , 11 Nov 2021 |

|

|

0 members, 1 guests, 0 anonymous users