Current stage-

Build thread -

The mini is in the building

After many, many, many years of neglect, perhaps TEN, the mini is at long last warm and snug in my garage.

The plan is for a full strip down, weld-a-thon, and then paint. Followed by a sensible engine choice of the 998 variety, but who no's, only time will tell.

Here are some pics.

The first stage is to strip the mini down to bare shell........

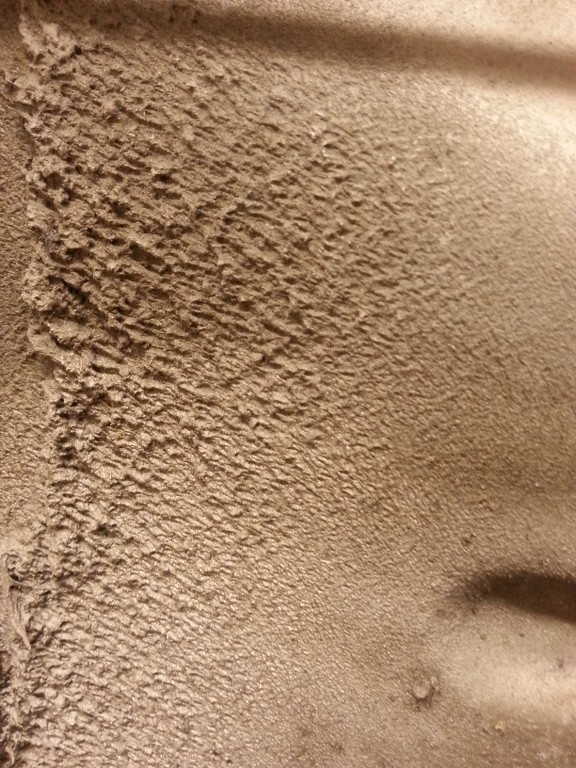

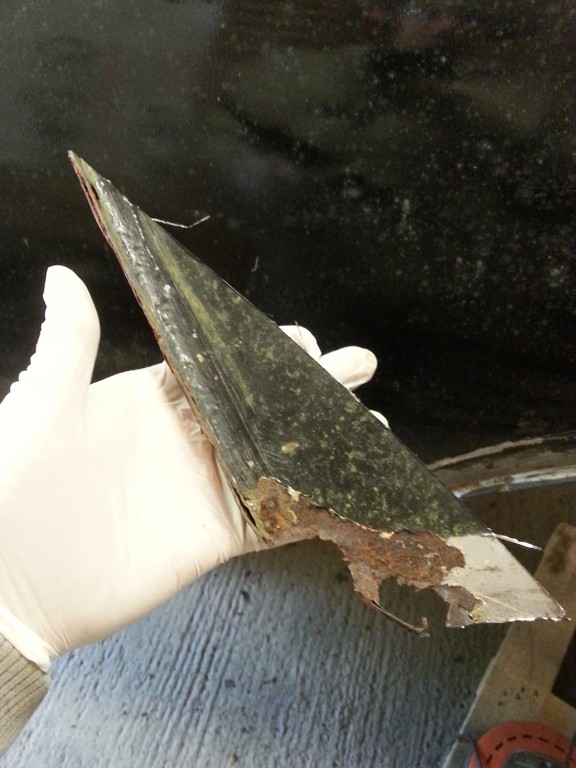

and then get poking with the trusty rust finding device (RFD) aka the screwdriver

so........ after finding all this rust what does any sane man do but buy a welder, a tank of argon, some 1mm cutting discs and a cheeky flap disc of course....

One small problem, I don't no how to weld ![]()

Stage two.... Welding

Lets see now, electric plus argon apparently equates to welds... good stuff. Lets see if I can make things stick together.

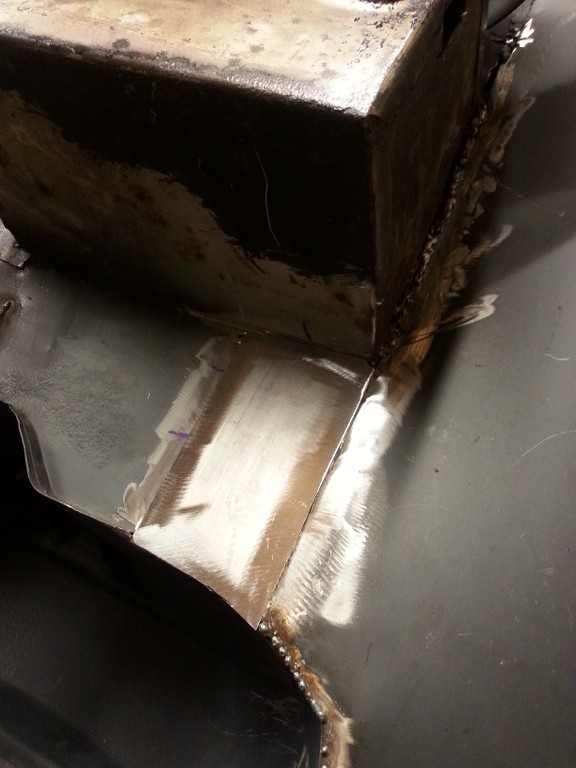

dodgy oversill purchased many years ago, cut in half and cleaned up ready for tack welds. Im experimenting with my butt welds.

cheeky few tacks, not bad for only 1hr play time with this beast.

Time to read up on a few things........ http://www.mig-weldi...uk/tutorial.htm

Right sooo, the trick is to pulse the weld, lets try this......

Not too bad for only round two, lets see the penetration

Getting there, must remember to hold it in position for a fraction longer.

Time to grind this bad boy down and see what were left with.

Im happy with that. Time to see if I can replicate this on the real thing.

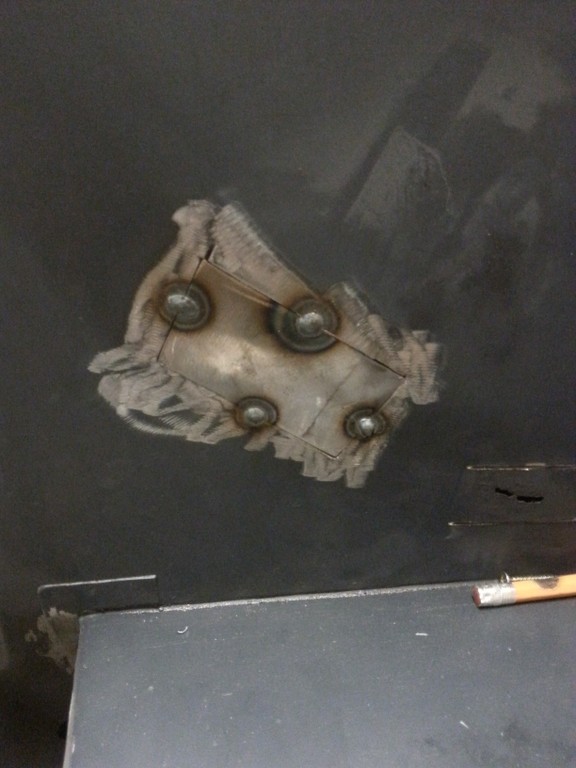

For obvious reasons I didn't want to jump ahead of my whooping 1Hr weld time so thought I would start with a simple job, blanking off the air intake hole in the driver wheel arch.

Offending flange removed

Time to make a template with some card and then cut it out of some new metal

Some fettling later...... a good fit

followed by those cheeky spot welds again, and checked for penetration

Next stage was to pulse weld between the tacks, making sure to leave time for the metal to cool between welding sessions, overkill perhaps, but im preparing my skills for a full butt weld in the boot !!!

Inside penetration, could be better

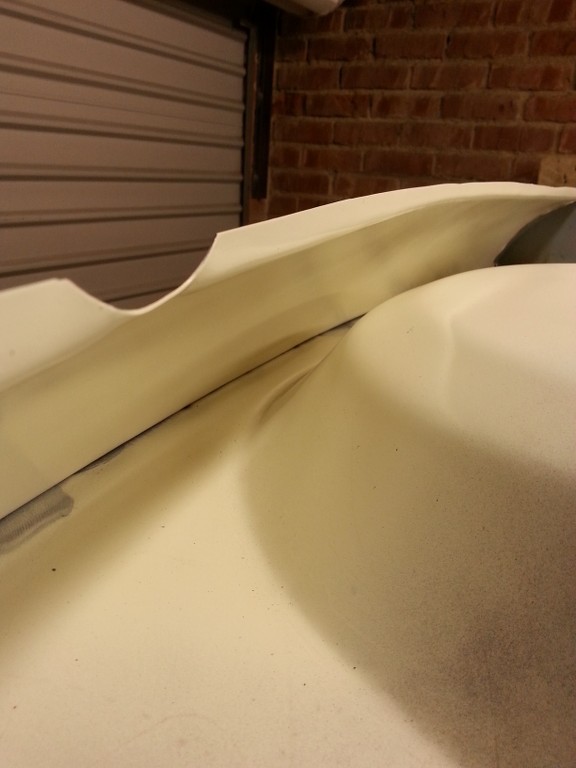

Then it was time to grind her back with my new favourite toy, the flap disc ala angle grinder.

some job.

And that's all folks, stay tuned for more learning curves.

The next stage is to 'aquire' some box section and build a rotating spit. Anyone have a 4m or longer scaffold pole, the straight pole type with no clamps on the ends?

edit: having just looked at this post my pics are very small, I will do larger ones next time. click on the pic for a bigger view and to be taken to my imageshack account.

All the best, David

Edited by bluemini17, 22 November 2017 - 11:12 PM.